Forging iron components involves shaping heated metal under high pressure, resulting in superior strength and durability compared to casting. Casting iron requires melting the metal and pouring it into molds, which allows for complex shapes but can introduce weaknesses like porosity and uneven grain structures. Forged parts are preferred for critical applications demanding high mechanical performance, while cast components are often chosen for intricate designs and cost-effectiveness.

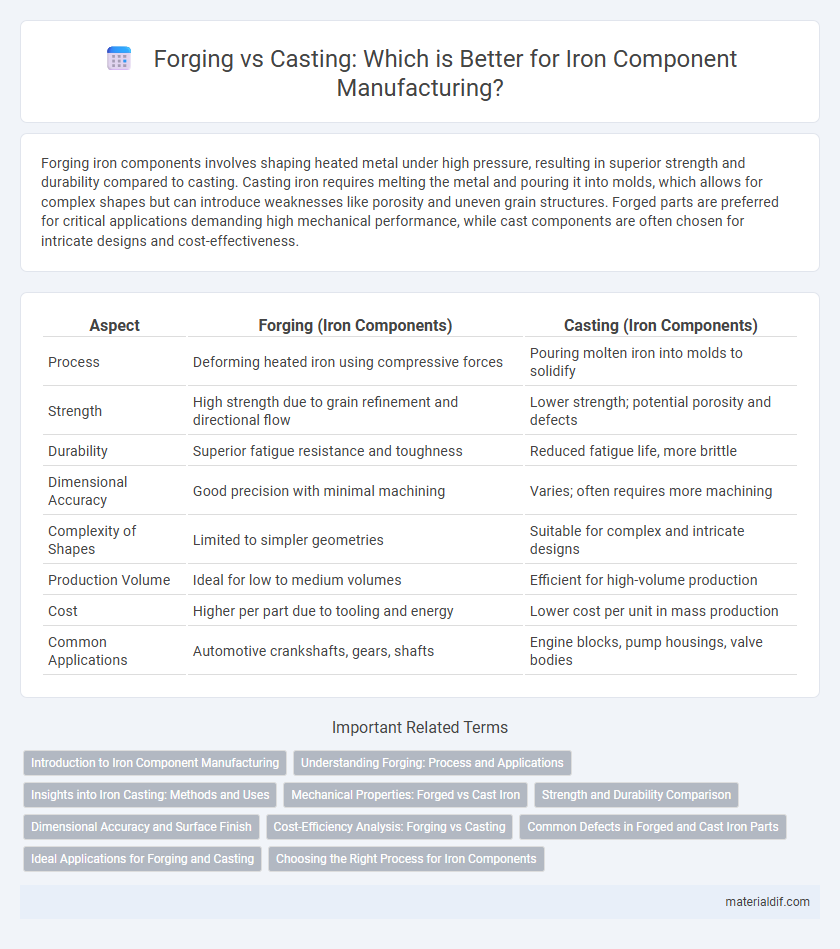

Table of Comparison

| Aspect | Forging (Iron Components) | Casting (Iron Components) |

|---|---|---|

| Process | Deforming heated iron using compressive forces | Pouring molten iron into molds to solidify |

| Strength | High strength due to grain refinement and directional flow | Lower strength; potential porosity and defects |

| Durability | Superior fatigue resistance and toughness | Reduced fatigue life, more brittle |

| Dimensional Accuracy | Good precision with minimal machining | Varies; often requires more machining |

| Complexity of Shapes | Limited to simpler geometries | Suitable for complex and intricate designs |

| Production Volume | Ideal for low to medium volumes | Efficient for high-volume production |

| Cost | Higher per part due to tooling and energy | Lower cost per unit in mass production |

| Common Applications | Automotive crankshafts, gears, shafts | Engine blocks, pump housings, valve bodies |

Introduction to Iron Component Manufacturing

Forging and casting are two primary manufacturing methods used to create iron components, each offering distinct mechanical properties and design flexibility. Forging involves shaping iron under high pressure, resulting in enhanced strength and fatigue resistance due to refined grain structures. Casting melts iron into molds, allowing complex geometries but often producing components with variable microstructures and potential porosity.

Understanding Forging: Process and Applications

Forging iron involves shaping the metal by applying compressive forces using a hammer or press, which refines the grain structure and enhances the mechanical properties for superior strength and toughness. Common applications include manufacturing high-stress components such as crankshafts, gears, and connecting rods, where durability and fatigue resistance are critical. The forging process produces components with fewer defects, improved impact resistance, and better load-bearing capacity compared to casting.

Insights into Iron Casting: Methods and Uses

Iron casting involves pouring molten iron into molds to create complex shapes with excellent dimensional accuracy and surface finish. Common casting methods include sand casting, investment casting, and die casting, each offering distinct benefits for producing components such as engine blocks, pipes, and machine parts. This process enables the manufacture of intricate designs and large-scale components that are difficult or costly to achieve through forging, making casting essential for diverse industrial applications.

Mechanical Properties: Forged vs Cast Iron

Forged iron components exhibit superior mechanical properties compared to cast iron, including higher tensile strength, improved toughness, and greater fatigue resistance due to the refined grain structure achieved through forging. Cast iron, while easier to produce, typically has higher brittleness and lower impact resistance because of its graphite microstructure and inherent porosity. These differences make forged iron ideal for critical applications requiring durability and resilience under dynamic loads.

Strength and Durability Comparison

Forged iron components exhibit superior strength due to grain structure alignment achieved through plastic deformation under high pressure, resulting in enhanced toughness and fatigue resistance. Cast iron components, while offering complex shapes and cost-effective production, typically contain porosity and material inconsistencies that reduce overall durability and impact resistance. The forging process produces denser, more uniform microstructures that withstand cyclic stresses better than the brittle nature of cast iron, making forged parts preferable for high-stress applications.

Dimensional Accuracy and Surface Finish

Forging iron components achieves superior dimensional accuracy due to precise control over deformation, resulting in consistent and uniform microstructure. Surface finishes in forged iron parts are generally smoother with fewer defects compared to casting, which often requires post-processing to correct rough textures and imperfections. Casting iron components can exhibit dimensional variability caused by shrinkage and mold design limitations, impacting overall tolerance and surface quality.

Cost-Efficiency Analysis: Forging vs Casting

Forging iron components typically involves higher initial tooling costs but results in superior mechanical properties and reduced material waste, making it more cost-efficient for high-strength applications and large production volumes. Casting incurs lower upfront costs and allows complex shapes to be produced economically in smaller batches, but it often leads to increased post-processing expenses due to porosity and dimensional inaccuracies. Evaluating cost-efficiency requires balancing production scale, material performance requirements, and long-term durability between forging and casting methodologies.

Common Defects in Forged and Cast Iron Parts

Forged iron components often exhibit defects such as laps, folds, and internal cracks due to improper die filling and excessive deformation, affecting mechanical strength. Cast iron parts frequently face issues like porosity, shrinkage cavities, and inclusions because of uneven cooling and gas entrapment during solidification. Understanding these common defects is crucial for optimizing manufacturing processes and ensuring the structural integrity of iron components in industrial applications.

Ideal Applications for Forging and Casting

Forging iron components is ideal for applications requiring high strength, toughness, and fatigue resistance, such as automotive crankshafts, aerospace parts, and heavy machinery. Casting suits complex shapes and large iron parts with intricate geometries, commonly used in engine blocks, pump housings, and decorative architectural elements. Engineers select forging for enhanced mechanical properties and casting for design flexibility and cost-efficiency in mass production.

Choosing the Right Process for Iron Components

Forging iron components enhances mechanical strength and grain structure by applying compressive forces, making it ideal for high-stress applications where durability is critical. Casting offers greater design flexibility and cost-efficiency for complex shapes and large production runs, but may result in lower tensile strength and potential porosity. Selecting the right process depends on the required mechanical properties, component geometry, and production volume for optimal performance and cost-effectiveness.

Forging vs Casting (Iron Components) Infographic

materialdif.com

materialdif.com