Powder metallurgy offers superior control over microstructure and composition compared to traditional casting, enabling the production of iron components with enhanced mechanical properties and reduced defects. This process minimizes material waste and allows for near-net shape manufacturing, which improves dimensional accuracy and reduces post-processing costs. Traditional casting remains advantageous for large, complex shapes but often results in coarser grain structures and higher porosity, affecting the overall strength and durability of iron parts.

Table of Comparison

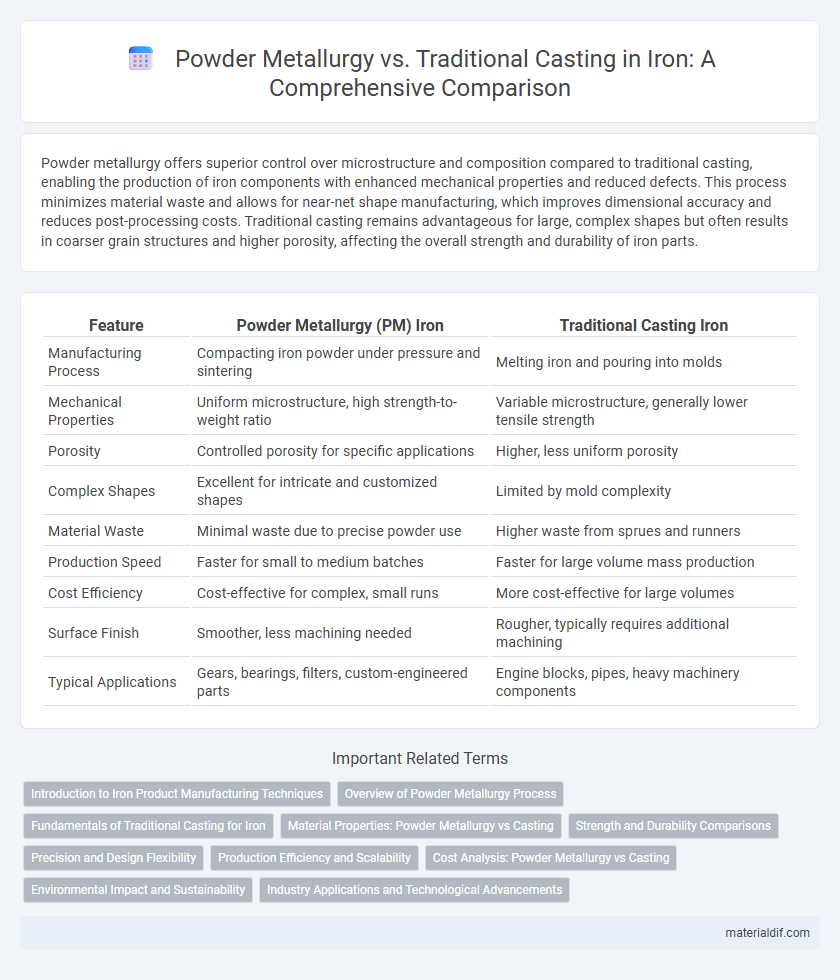

| Feature | Powder Metallurgy (PM) Iron | Traditional Casting Iron |

|---|---|---|

| Manufacturing Process | Compacting iron powder under pressure and sintering | Melting iron and pouring into molds |

| Mechanical Properties | Uniform microstructure, high strength-to-weight ratio | Variable microstructure, generally lower tensile strength |

| Porosity | Controlled porosity for specific applications | Higher, less uniform porosity |

| Complex Shapes | Excellent for intricate and customized shapes | Limited by mold complexity |

| Material Waste | Minimal waste due to precise powder use | Higher waste from sprues and runners |

| Production Speed | Faster for small to medium batches | Faster for large volume mass production |

| Cost Efficiency | Cost-effective for complex, small runs | More cost-effective for large volumes |

| Surface Finish | Smoother, less machining needed | Rougher, typically requires additional machining |

| Typical Applications | Gears, bearings, filters, custom-engineered parts | Engine blocks, pipes, heavy machinery components |

Introduction to Iron Product Manufacturing Techniques

Powder metallurgy offers superior control over the microstructure and composition of iron products compared to traditional casting, enabling the production of components with enhanced mechanical properties and reduced defects. Traditional casting involves melting and pouring molten iron into molds, which can lead to issues such as porosity and segregation, whereas powder metallurgy compacts and sinters fine iron powders to achieve near-net shape parts with minimal waste. This advanced technique allows for precise tailoring of iron product characteristics, crucial for automotive, aerospace, and industrial applications.

Overview of Powder Metallurgy Process

The powder metallurgy process for iron involves compacting fine iron powders into desired shapes followed by sintering at high temperatures to bond particles and achieve mechanical strength. This method allows precise control over microstructure, density, and composition, resulting in improved material properties such as enhanced wear resistance and reduced porosity compared to traditional casting. Powder metallurgy also enables near-net shape manufacturing, minimizing material waste and machining costs while providing uniformity in complex geometries.

Fundamentals of Traditional Casting for Iron

Traditional casting of iron involves melting raw iron and pouring it into molds to solidify, relying on gravity and cooling rates to shape the final product. Key fundamentals include mold material selection, typically sand or metal molds, and controlling the cooling process to prevent defects such as porosity and shrinkage. The method allows for large, complex shapes but requires careful management of thermal contractions and solidification patterns to ensure structural integrity and dimensional accuracy.

Material Properties: Powder Metallurgy vs Casting

Powder metallurgy produces iron components with finer microstructures, resulting in superior mechanical properties such as higher tensile strength, wear resistance, and fatigue endurance compared to traditional casting. The controlled particle size and uniform distribution of alloying elements in powder metallurgy reduce porosity and improve dimensional accuracy. In contrast, casting often leads to coarser grains and greater internal defects, which can compromise the material's structural integrity and performance.

Strength and Durability Comparisons

Powder metallurgy iron exhibits superior strength and durability compared to traditional casting due to its fine, uniform microstructure and reduced porosity. The controlled particle size and sintering process in powder metallurgy result in enhanced mechanical properties, including higher tensile strength and improved wear resistance. Traditional casting often leads to coarse grains and defects like shrinkage porosity, which can compromise the material's overall strength and longevity.

Precision and Design Flexibility

Powder metallurgy offers superior precision and tighter dimensional tolerances compared to traditional casting, enabling complex iron components with intricate geometries to be produced consistently. This method allows enhanced design flexibility by facilitating near-net shape manufacturing, reducing material waste and machining requirements. Traditional casting, while effective for large and simple shapes, often requires extensive post-processing and may exhibit inherent defects affecting both precision and customization.

Production Efficiency and Scalability

Powder metallurgy offers superior production efficiency for iron components by minimizing material waste and enabling near-net shape manufacturing, reducing machining costs. Its scalability is enhanced through consistent batch processing and ease of automation, allowing rapid adaptation to volume changes. Traditional casting, while suitable for large, complex shapes, often involves longer cycle times and higher scrap rates, limiting its efficiency and flexibility in mass production.

Cost Analysis: Powder Metallurgy vs Casting

Powder metallurgy offers cost advantages over traditional casting by minimizing material waste and reducing energy consumption during production. Although initial tooling expenses for powder metallurgy can be higher, the process enables precise control over iron powder compaction and sintering, leading to lower machining costs. In contrast, traditional casting involves significant post-casting machining and larger energy use, increasing overall expenses despite lower initial mold costs.

Environmental Impact and Sustainability

Powder metallurgy of iron significantly reduces material waste and energy consumption compared to traditional casting, promoting eco-friendly production. This method minimizes emissions and lowers the carbon footprint by requiring less melting and machining, thus conserving natural resources. Enhanced recycling potential and precise control over alloy composition further contribute to the sustainability advantages of powder metallurgy in iron manufacturing.

Industry Applications and Technological Advancements

Powder metallurgy of iron offers precise control over microstructure and composition, enabling superior mechanical properties suited for automotive and aerospace components. Traditional casting remains prevalent in heavy machinery and construction due to its cost-efficiency and ability to produce large, complex iron parts. Advances in powder metallurgy, including additive manufacturing and sintering technologies, have enhanced production speed and material uniformity, expanding its applications in high-performance industrial sectors.

Powder Metallurgy vs Traditional Casting Infographic

materialdif.com

materialdif.com