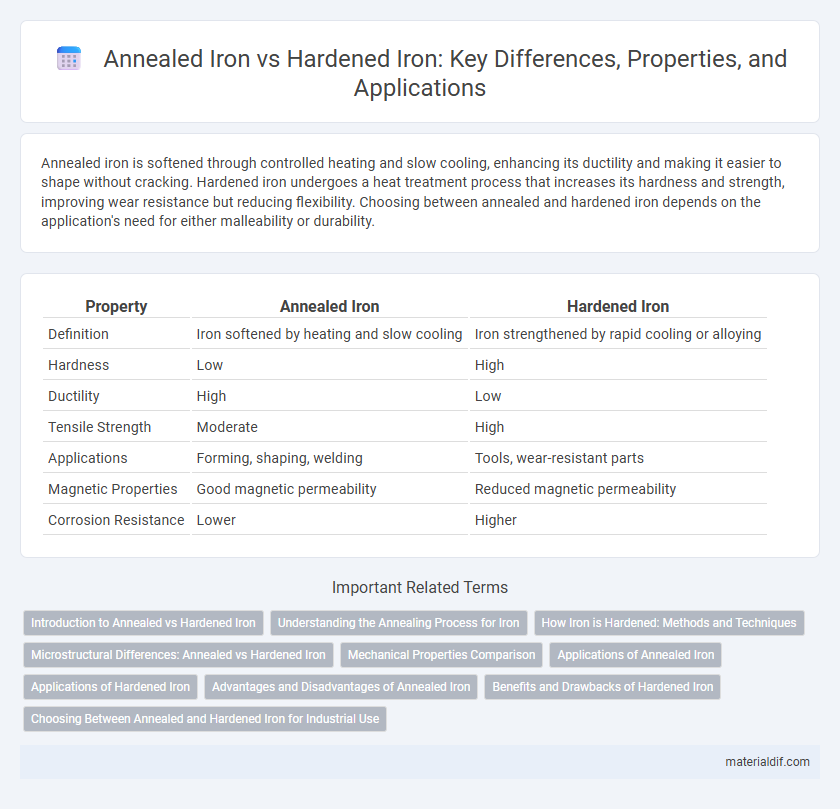

Annealed iron is softened through controlled heating and slow cooling, enhancing its ductility and making it easier to shape without cracking. Hardened iron undergoes a heat treatment process that increases its hardness and strength, improving wear resistance but reducing flexibility. Choosing between annealed and hardened iron depends on the application's need for either malleability or durability.

Table of Comparison

| Property | Annealed Iron | Hardened Iron |

|---|---|---|

| Definition | Iron softened by heating and slow cooling | Iron strengthened by rapid cooling or alloying |

| Hardness | Low | High |

| Ductility | High | Low |

| Tensile Strength | Moderate | High |

| Applications | Forming, shaping, welding | Tools, wear-resistant parts |

| Magnetic Properties | Good magnetic permeability | Reduced magnetic permeability |

| Corrosion Resistance | Lower | Higher |

Introduction to Annealed vs Hardened Iron

Annealed iron undergoes a heat treatment process to increase its ductility and reduce hardness, making it more malleable and easier to shape. Hardened iron is subjected to controlled cooling to increase its strength and wear resistance, resulting in a tougher, less flexible material. Understanding the differences in stress relief and mechanical properties helps optimize material selection for industrial applications.

Understanding the Annealing Process for Iron

Annealed iron undergoes a controlled heating and slow cooling process that relieves internal stresses, resulting in increased ductility and reduced hardness. This heat treatment allows the iron's crystal structure to reorganize, improving its machinability and making it easier to shape or form. In contrast, hardened iron experiences rapid cooling after heating, leading to a brittle structure optimized for strength but less suited for further processing.

How Iron is Hardened: Methods and Techniques

Hardened iron is produced through heat treatment methods such as quenching and tempering, which involve heating the iron to high temperatures followed by rapid cooling to increase its hardness and durability. Techniques like carburizing and nitriding introduce carbon or nitrogen into the iron surface to enhance wear resistance and strength without compromising core toughness. These processes alter the microstructure of iron, transforming softer phases into harder ones such as martensite, making hardened iron ideal for industrial applications requiring high mechanical performance.

Microstructural Differences: Annealed vs Hardened Iron

Annealed iron exhibits a coarse pearlitic or ferritic microstructure with evenly distributed carbon atoms, resulting in enhanced ductility and reduced hardness. Hardened iron undergoes rapid cooling processes like quenching, leading to the formation of martensitic or bainitic microstructures characterized by increased dislocation density and trapped carbon atoms, which substantially increase strength and hardness. These microstructural differences directly influence mechanical properties, making annealed iron suitable for forming and machining, while hardened iron excels in wear resistance and structural applications.

Mechanical Properties Comparison

Annealed iron exhibits lower tensile strength and higher ductility compared to hardened iron, making it more malleable and easier to shape without cracking. Hardened iron undergoes heat treatment that increases its hardness and tensile strength, resulting in improved wear resistance and reduced deformation under mechanical stress. The mechanical properties difference is key for selecting materials in applications demanding either flexibility or high strength and durability.

Applications of Annealed Iron

Annealed iron is primarily used in applications requiring high malleability and ductility, such as automotive body panels, wire manufacturing, and metal forming processes. Its softened structure allows for easy shaping and welding, making it ideal for crafting complex components and artistic metalwork. Due to its resistance to cracking during deformation, annealed iron is favored in industries where precision and flexibility are crucial.

Applications of Hardened Iron

Hardened iron, known for its enhanced strength and wear resistance, is widely used in industrial machinery components, automotive parts, and heavy-duty tools requiring durability under high stress. Its applications include gears, crankshafts, and cutting tools where resistance to deformation and abrasion is critical for performance. The material's superior hardness and fatigue resistance make it ideal for manufacturing parts exposed to repetitive mechanical loads and harsh operating environments.

Advantages and Disadvantages of Annealed Iron

Annealed iron offers superior ductility and malleability compared to hardened iron, making it easier to shape and weld for manufacturing processes. Its lower hardness reduces brittleness, minimizing the risk of cracking under tensile stress but limits its wear resistance and structural strength in heavy-duty applications. This trade-off makes annealed iron ideal for components requiring flexibility and machining, while hardened iron is preferred for durability and abrasion resistance.

Benefits and Drawbacks of Hardened Iron

Hardened iron offers superior strength and wear resistance compared to annealed iron, making it ideal for applications requiring durability and toughness, such as machinery parts and tools. Its increased hardness can, however, lead to brittleness, reducing its impact resistance and making it more prone to cracking under sudden stress. While annealed iron is softer and more ductile, hardened iron's enhanced mechanical properties provide significant benefits in heavy-duty environments despite its limited flexibility.

Choosing Between Annealed and Hardened Iron for Industrial Use

Annealed iron offers enhanced ductility and machinability due to its softened microstructure, making it ideal for processes requiring bending or shaping in industrial applications. Hardened iron provides superior strength and wear resistance, suitable for components subjected to heavy loads and abrasive environments. Selecting between annealed and hardened iron depends on balancing the need for flexibility versus durability in manufacturing processes.

Annealed Iron vs Hardened Iron Infographic

materialdif.com

materialdif.com