Iron ore is a naturally occurring mineral from which metallic iron is extracted, containing iron oxides such as hematite and magnetite. Pig iron is the intermediate product obtained by smelting iron ore in a blast furnace, characterized by a high carbon content that makes it brittle and unsuitable for direct use. The primary difference lies in their form and composition; iron ore is raw material, while pig iron serves as the base for producing steel and other iron products.

Table of Comparison

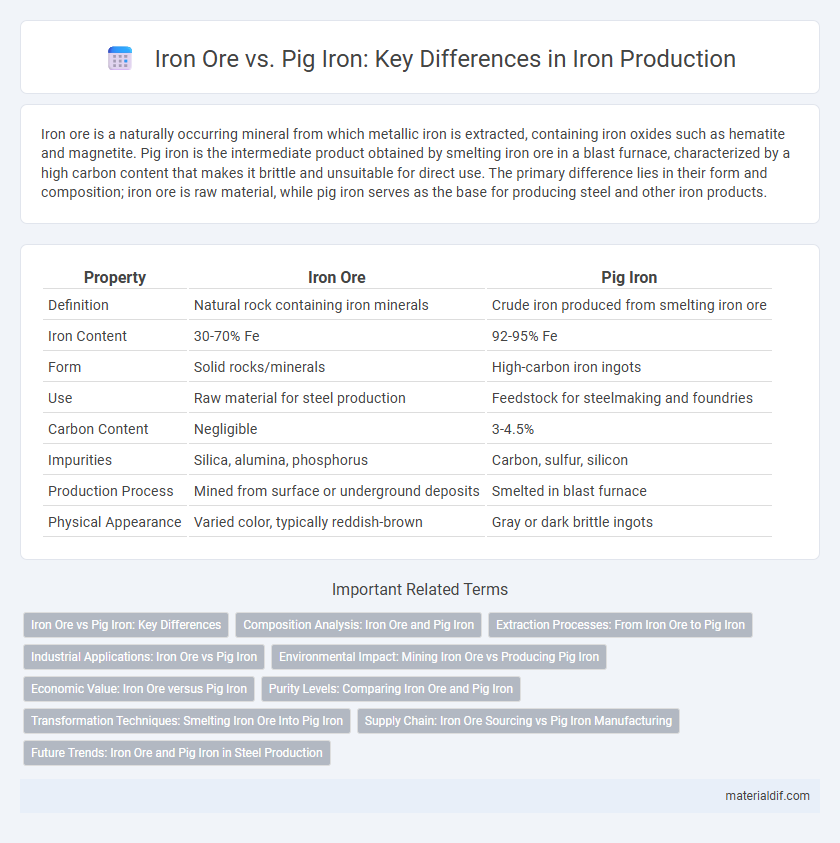

| Property | Iron Ore | Pig Iron |

|---|---|---|

| Definition | Natural rock containing iron minerals | Crude iron produced from smelting iron ore |

| Iron Content | 30-70% Fe | 92-95% Fe |

| Form | Solid rocks/minerals | High-carbon iron ingots |

| Use | Raw material for steel production | Feedstock for steelmaking and foundries |

| Carbon Content | Negligible | 3-4.5% |

| Impurities | Silica, alumina, phosphorus | Carbon, sulfur, silicon |

| Production Process | Mined from surface or underground deposits | Smelted in blast furnace |

| Physical Appearance | Varied color, typically reddish-brown | Gray or dark brittle ingots |

Iron Ore vs Pig Iron: Key Differences

Iron ore is a naturally occurring mineral from which iron is extracted, primarily composed of iron oxides such as hematite and magnetite. Pig iron is the intermediate product obtained by smelting iron ore in a blast furnace, containing about 3-4% carbon along with impurities like silicon, manganese, and sulfur. The key differences lie in their composition and purpose: iron ore is the raw material, while pig iron serves as the base for producing steel and wrought iron through subsequent refining processes.

Composition Analysis: Iron Ore and Pig Iron

Iron ore primarily consists of iron oxides such as hematite (Fe2O3) and magnetite (Fe3O4), with varying amounts of silica, alumina, and other impurities. Pig iron contains around 90-95% iron, combined with 3-4.5% carbon, along with silicon, manganese, sulfur, and phosphorus as minor constituents. The composition differences reflect the transformation from raw mineral in iron ore to a more refined, carbon-rich intermediate material in pig iron used for steelmaking.

Extraction Processes: From Iron Ore to Pig Iron

Iron ore undergoes crushing, grinding, and magnetic separation to concentrate the ore before it is fed into a blast furnace. In the blast furnace, iron ore is reduced chemically by coke and limestone at high temperatures to produce molten pig iron. This pig iron contains 3-4.5% carbon and other impurities, making it a key intermediate product in steel manufacturing.

Industrial Applications: Iron Ore vs Pig Iron

Iron ore serves as the primary raw material in the steelmaking process, containing iron oxides that are extracted and refined. Pig iron, produced by smelting iron ore with coke and limestone in a blast furnace, acts as an intermediate product with a high carbon content used mainly for casting and further steel production. Industrial applications rely on iron ore for raw input in iron and steel manufacturing, while pig iron's role is critical for producing cast iron and as a feedstock in steelmaking facilities.

Environmental Impact: Mining Iron Ore vs Producing Pig Iron

Mining iron ore generates significant environmental impacts including habitat disruption, soil erosion, and water contamination due to the extraction process. Producing pig iron involves energy-intensive blast furnace operations that emit large amounts of carbon dioxide and other greenhouse gases. The combined effects of ore extraction and pig iron production contribute heavily to deforestation, air pollution, and increased carbon footprints within the iron and steel industry.

Economic Value: Iron Ore versus Pig Iron

Iron ore serves as the essential raw material for pig iron production, with its economic value largely influenced by ore grade, extraction costs, and global demand for steelmaking inputs. Pig iron holds greater economic value than raw iron ore as it is a semi-refined product ready for conversion into steel, thus commanding higher market prices due to its added processing and enhanced usability. Market fluctuations in iron ore prices directly impact pig iron costs, but pig iron's value reflects downstream processing efficiencies and its critical role in the steel industry supply chain.

Purity Levels: Comparing Iron Ore and Pig Iron

Iron ore typically contains 50-70% iron along with impurities such as silica, sulfur, and phosphorus, affecting its overall purity. Pig iron, produced by smelting iron ore in a blast furnace, has a higher iron content of around 92-95% but still contains carbon and other impurities like manganese and sulfur. The increased purity in pig iron makes it a more suitable raw material for further refining into steel.

Transformation Techniques: Smelting Iron Ore Into Pig Iron

Smelting iron ore into pig iron involves heating the ore in a blast furnace with coke and limestone, which reduces iron oxides to molten iron while removing impurities. The chemical reactions in the furnace convert iron ore (Fe2O3 or Fe3O4) into liquid pig iron containing about 3.5-4.5% carbon along with other elements such as sulfur, phosphorus, and silicon. This transformation technique is fundamental for producing pig iron as a raw material for steelmaking and foundry applications.

Supply Chain: Iron Ore Sourcing vs Pig Iron Manufacturing

Iron ore sourcing involves the extraction and transportation of raw iron ore from mining sites to processing plants, emphasizing logistics efficiency and quality control to meet steel industry demand. Pig iron manufacturing centers on smelting iron ore with coke and limestone in blast furnaces, transforming raw ore into a semi-finished product with high carbon content for downstream steel production. Supply chain management between these stages is critical to ensure timely delivery, cost optimization, and maintaining consistent quality standards across the iron and steel supply network.

Future Trends: Iron Ore and Pig Iron in Steel Production

Iron ore, the primary raw material for steel production, is expected to see increased demand driven by technological advancements in beneficiation and pelletizing, enhancing ore quality and yield. Pig iron, produced by smelting iron ore in blast furnaces, will continue to play a crucial role but faces pressure from alternative processes like electric arc furnaces that utilize recycled scrap for greener steelmaking. Future trends indicate a shift toward more sustainable and energy-efficient production methods, incorporating hydrogen-based reduction technologies and circular economy principles to reduce carbon emissions in steel manufacturing.

Iron Ore vs Pig Iron Infographic

materialdif.com

materialdif.com