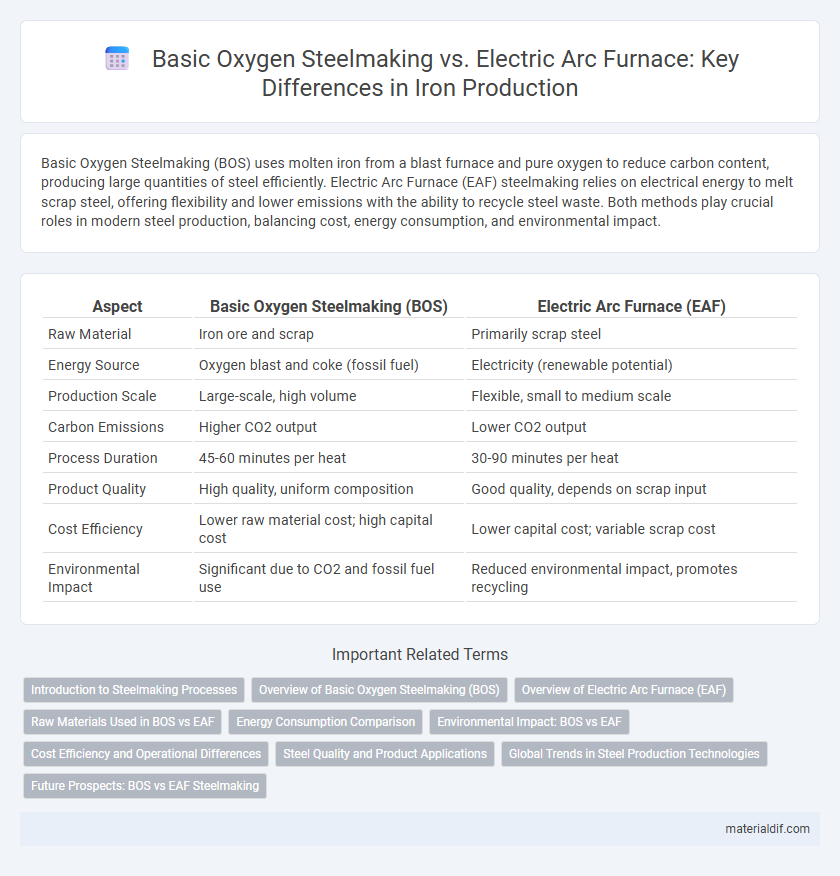

Basic Oxygen Steelmaking (BOS) uses molten iron from a blast furnace and pure oxygen to reduce carbon content, producing large quantities of steel efficiently. Electric Arc Furnace (EAF) steelmaking relies on electrical energy to melt scrap steel, offering flexibility and lower emissions with the ability to recycle steel waste. Both methods play crucial roles in modern steel production, balancing cost, energy consumption, and environmental impact.

Table of Comparison

| Aspect | Basic Oxygen Steelmaking (BOS) | Electric Arc Furnace (EAF) |

|---|---|---|

| Raw Material | Iron ore and scrap | Primarily scrap steel |

| Energy Source | Oxygen blast and coke (fossil fuel) | Electricity (renewable potential) |

| Production Scale | Large-scale, high volume | Flexible, small to medium scale |

| Carbon Emissions | Higher CO2 output | Lower CO2 output |

| Process Duration | 45-60 minutes per heat | 30-90 minutes per heat |

| Product Quality | High quality, uniform composition | Good quality, depends on scrap input |

| Cost Efficiency | Lower raw material cost; high capital cost | Lower capital cost; variable scrap cost |

| Environmental Impact | Significant due to CO2 and fossil fuel use | Reduced environmental impact, promotes recycling |

Introduction to Steelmaking Processes

Basic Oxygen Steelmaking (BOS) and Electric Arc Furnace (EAF) are two primary steelmaking processes that significantly influence iron refining methods. BOS utilizes molten iron from blast furnaces and introduces oxygen to reduce carbon content, producing large volumes of steel efficiently. In contrast, EAF melts scrap steel or direct reduced iron using electric arcs, offering flexibility and lower carbon emissions, making it ideal for recycling and specialty steel production.

Overview of Basic Oxygen Steelmaking (BOS)

Basic Oxygen Steelmaking (BOS) is a primary method of steel production that converts molten iron from a blast furnace into steel by blowing high-purity oxygen through the molten iron, dramatically reducing carbon content. This process typically achieves high productivity with capacities ranging from 100 to 350 tons per heat and a cycle time of 30-60 minutes, making it suitable for mass steel production. BOS is favored for producing large volumes of flat steel products due to its efficiency and relatively low operating costs compared to Electric Arc Furnace (EAF) methods.

Overview of Electric Arc Furnace (EAF)

Electric Arc Furnace (EAF) technology uses electrical energy to melt scrap steel, enabling efficient and flexible steel production with lower carbon emissions compared to Basic Oxygen Steelmaking (BOS). EAFs support high recycling rates and allow for precise control over alloy composition, making them ideal for specialty and high-grade steel manufacturing. The process is characterized by shorter production cycles and reduced raw material dependency, enhancing sustainability in modern steel industries.

Raw Materials Used in BOS vs EAF

Basic Oxygen Steelmaking (BOS) primarily uses molten pig iron from blast furnaces combined with scrap steel and flux materials like limestone. Electric Arc Furnace (EAF) steelmaking predominantly relies on recycled steel scrap and direct reduced iron (DRI) with minimal use of virgin raw iron ore. The difference in raw materials directly impacts energy consumption, production flexibility, and the carbon footprint of each steelmaking process.

Energy Consumption Comparison

Basic Oxygen Steelmaking (BOS) consumes approximately 20-40 GJ per ton of steel, primarily relying on coke and coal, resulting in higher carbon emissions. Electric Arc Furnace (EAF) technology uses around 3-6 GJ per ton of steel by melting scrap steel with electric energy, offering significantly lower energy consumption and reduced environmental impact. The energy efficiency of EAF is enhanced by advancements in electric power sources and recycling processes, making it a more sustainable option for steel production.

Environmental Impact: BOS vs EAF

Basic Oxygen Steelmaking (BOS) produces higher CO2 emissions due to the use of carbon-rich raw materials and reliance on blast furnaces, contributing significantly to industrial greenhouse gases. Electric Arc Furnace (EAF) technology uses primarily recycled scrap steel and electricity, enabling lower direct carbon emissions and greater potential for integration with renewable energy sources. The environmental impact of EAF is generally reduced compared to BOS, making it a more sustainable option in steel production from a carbon footprint perspective.

Cost Efficiency and Operational Differences

Basic Oxygen Steelmaking (BOS) typically offers higher cost efficiency for large-scale production due to lower energy consumption per ton of steel compared to Electric Arc Furnace (EAF) processes, which rely heavily on electricity and scrap metal input. BOS operations require continuous, integrated infrastructure and raw materials such as iron ore and coke, while EAF allows greater operational flexibility with intermittent batch production and easier adaptation to varying scrap quality. The higher capital intensity and environmental controls in BOS contrast with EAF's advantages in reduced emissions and faster startup times, influencing operational cost structures and scalability.

Steel Quality and Product Applications

Basic Oxygen Steelmaking (BOS) produces high-quality steel with low impurities, ideal for large-scale applications in automotive and construction industries due to its consistency and tensile strength. Electric Arc Furnace (EAF) excels in recycling scrap steel with flexible production and lower energy consumption, yielding steel suitable for specialized, high-alloy products and customizable applications. Both methods yield distinct steel grades, where BOS is preferred for structural steel, while EAF targets niche markets requiring precise chemical compositions.

Global Trends in Steel Production Technologies

Global trends in steel production technologies reveal a shift towards Electric Arc Furnace (EAF) methods, driven by their lower carbon emissions and ability to recycle scrap steel efficiently. Basic Oxygen Steelmaking (BOS) remains dominant in regions rich in iron ore, particularly in emerging economies, due to its cost-effectiveness for large-scale production. The increasing adoption of EAF reflects industry efforts to meet sustainability targets while adapting to fluctuating raw material availability worldwide.

Future Prospects: BOS vs EAF Steelmaking

Electric Arc Furnace (EAF) steelmaking is gaining prominence due to its lower carbon emissions and flexibility in using scrap metal, aligning with global sustainability goals. Basic Oxygen Steelmaking (BOS) remains essential for processing large volumes of iron ore into steel but faces challenges in reducing its environmental impact. Future steel production increasingly favors EAF for decarbonization and circular economy integration, while advanced BOS technologies explore carbon capture and hydrogen use to maintain competitiveness.

Basic Oxygen Steelmaking vs Electric Arc Furnace Infographic

materialdif.com

materialdif.com