Powder metallurgy involves producing iron components by pressing powdered metal into a desired shape before sintering, which uses heat below the melting point to bond particles. Sintering enhances the density and mechanical properties of the iron parts by facilitating atomic diffusion at elevated temperatures. This combination leads to improved strength, wear resistance, and dimensional accuracy compared to traditional casting methods.

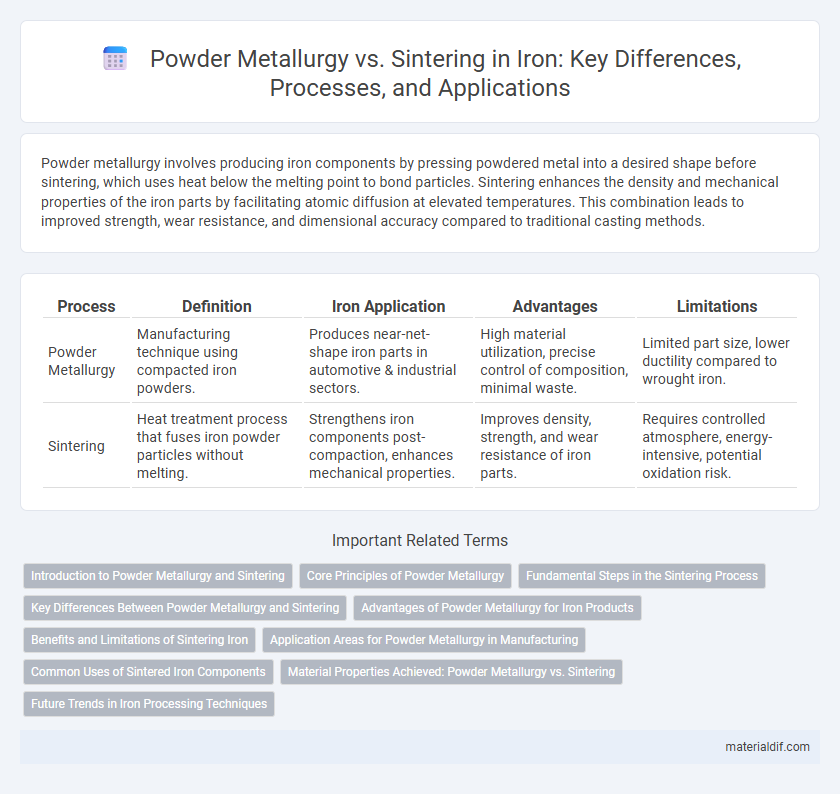

Table of Comparison

| Process | Definition | Iron Application | Advantages | Limitations |

|---|---|---|---|---|

| Powder Metallurgy | Manufacturing technique using compacted iron powders. | Produces near-net-shape iron parts in automotive & industrial sectors. | High material utilization, precise control of composition, minimal waste. | Limited part size, lower ductility compared to wrought iron. |

| Sintering | Heat treatment process that fuses iron powder particles without melting. | Strengthens iron components post-compaction, enhances mechanical properties. | Improves density, strength, and wear resistance of iron parts. | Requires controlled atmosphere, energy-intensive, potential oxidation risk. |

Introduction to Powder Metallurgy and Sintering

Powder metallurgy involves producing iron components by compacting fine iron powders and heating them below melting temperatures to form solid parts, optimizing microstructure and mechanical properties. Sintering, a critical step in powder metallurgy, binds iron particles through diffusion processes at elevated temperatures, enhancing density and strength without melting the material. This method enables precise control over material composition and porosity, crucial for advanced iron-based applications in automotive and industrial sectors.

Core Principles of Powder Metallurgy

Powder metallurgy revolves around producing metal components by compacting fine iron powders into desired shapes under high pressure, followed by heating below the melting point to bond particles. This process enhances material utilization, dimensional accuracy, and mechanical properties compared to traditional casting methods. Sintering, a critical stage in powder metallurgy, involves the controlled heating of iron powder compacts to facilitate diffusion and particle bonding, resulting in dense, strong iron composites.

Fundamental Steps in the Sintering Process

Sintering is a crucial step in powder metallurgy, involving the heating of compacted iron powders below their melting point to facilitate atomic diffusion and bonding. Fundamental steps include particle rearrangement, neck formation between iron particles, and densification through mass transport mechanisms like surface diffusion, grain boundary diffusion, and volume diffusion. This process enhances mechanical properties and structural integrity by reducing porosity and increasing the density of the iron component.

Key Differences Between Powder Metallurgy and Sintering

Powder metallurgy involves producing metal components by compressing metal powders into desired shapes before heating, while sintering specifically refers to the heating process that bonds particles without melting them fully. Powder metallurgy encompasses multiple steps, including powder preparation, compaction, sintering, and finishing, whereas sintering is a single thermal operation within this sequence. The primary difference lies in powder metallurgy being a comprehensive manufacturing technique, while sintering is a critical process step that consolidates the powders into solid iron parts.

Advantages of Powder Metallurgy for Iron Products

Powder metallurgy offers superior material utilization by minimizing waste and enabling precise control over iron product composition. This method enhances mechanical properties such as strength and wear resistance through uniform microstructure development. Complex shapes and intricate designs are achievable without extensive machining, reducing production costs and lead times.

Benefits and Limitations of Sintering Iron

Sintering iron in powder metallurgy enhances material density and mechanical properties by fusing powdered iron particles under controlled heat without melting, resulting in improved uniformity and reduced waste. Benefits include precise control over porosity and the ability to produce complex shapes with minimal machining, while limitations involve potential oxidation, dimensional shrinkage, and the need for consistent particle size distribution. Optimizing sintering parameters is critical to mitigate defects and maximize the strength and durability of iron components produced.

Application Areas for Powder Metallurgy in Manufacturing

Powder metallurgy is widely applied in manufacturing components for the automotive, aerospace, and tooling industries due to its precision and material efficiency in producing complex iron-based parts. This process enables the mass production of gears, bearings, filters, and structural components with enhanced mechanical properties and minimal waste. Sintering, a key step in powder metallurgy, solidifies powdered iron, improving toughness and durability essential for high-performance manufacturing applications.

Common Uses of Sintered Iron Components

Sintered iron components are widely used in automotive industries for manufacturing gears, bushings, and structural parts due to their excellent wear resistance and dimensional accuracy. Powder metallurgy enables precise control over material composition and porosity, achieving lightweight yet durable sintered iron products ideal for high-performance machinery. These applications benefit from sintering's ability to produce complex shapes with minimal machining, reducing manufacturing costs while maintaining mechanical strength.

Material Properties Achieved: Powder Metallurgy vs. Sintering

Powder metallurgy achieves enhanced material properties such as uniform microstructure, improved tensile strength, and excellent wear resistance due to precise control over powder particle size and composition. Sintering complements this by promoting particle bonding through controlled heating, resulting in increased density, mechanical integrity, and reduced porosity in iron components. Optimizing both processes leads to superior hardness, fatigue resistance, and corrosion resistance tailored for demanding industrial applications.

Future Trends in Iron Processing Techniques

Future trends in iron processing emphasize advancements in powder metallurgy with enhanced control over particle size distribution and alloy composition, leading to superior mechanical properties and reduced material waste. Innovative sintering techniques, such as spark plasma sintering and microwave sintering, enable faster densification at lower temperatures, improving energy efficiency and microstructural uniformity. Integration of additive manufacturing with powder metallurgy paves the way for complex iron components with optimized performance and sustainability in various industrial applications.

Powder Metallurgy vs Sintering Infographic

materialdif.com

materialdif.com