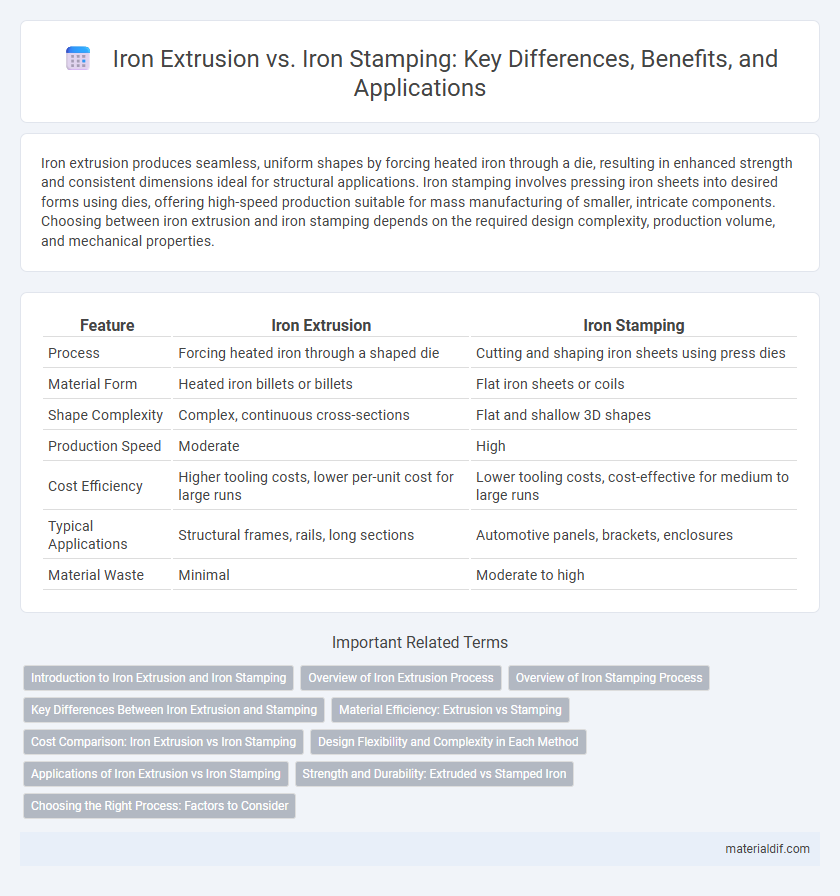

Iron extrusion produces seamless, uniform shapes by forcing heated iron through a die, resulting in enhanced strength and consistent dimensions ideal for structural applications. Iron stamping involves pressing iron sheets into desired forms using dies, offering high-speed production suitable for mass manufacturing of smaller, intricate components. Choosing between iron extrusion and iron stamping depends on the required design complexity, production volume, and mechanical properties.

Table of Comparison

| Feature | Iron Extrusion | Iron Stamping |

|---|---|---|

| Process | Forcing heated iron through a shaped die | Cutting and shaping iron sheets using press dies |

| Material Form | Heated iron billets or billets | Flat iron sheets or coils |

| Shape Complexity | Complex, continuous cross-sections | Flat and shallow 3D shapes |

| Production Speed | Moderate | High |

| Cost Efficiency | Higher tooling costs, lower per-unit cost for large runs | Lower tooling costs, cost-effective for medium to large runs |

| Typical Applications | Structural frames, rails, long sections | Automotive panels, brackets, enclosures |

| Material Waste | Minimal | Moderate to high |

Introduction to Iron Extrusion and Iron Stamping

Iron extrusion involves forcing heated iron through a die to create long, continuous shapes with uniform cross-sections, ideal for producing structural components and complex profiles. Iron stamping uses high-pressure presses to shape iron sheets or strips into precise parts by cutting, bending, or embossing, commonly applied in manufacturing automotive and appliance components. Both processes are essential in metal fabrication, with extrusion offering superior dimensional consistency and stamping providing high-speed production efficiency.

Overview of Iron Extrusion Process

Iron extrusion involves forcing heated iron billets through a die to create long, continuous shapes with uniform cross-sections, enhancing material strength and surface finish. This process allows for precise dimensional control and complex profiles, making it ideal for manufacturing structural components and intricate parts. Iron stamping, in contrast, primarily shapes flat sheets by cutting or pressing but lacks the continuous, seamless qualities of extruded iron products.

Overview of Iron Stamping Process

Iron stamping involves shaping iron sheets into specific forms using a stamping press and dies, allowing for high precision and repeatability in manufacturing complex parts. This process is ideal for producing large volumes of components with consistent dimensions and smooth finishes, commonly used in automotive and appliance industries. Compared to iron extrusion, stamping offers faster production times for thin and flat iron pieces but is less suitable for creating long, uniform profiles.

Key Differences Between Iron Extrusion and Stamping

Iron extrusion involves forcing heated iron through a die to create long shapes with a consistent cross-section, providing strong structural integrity and uniformity ideal for industrial applications. Iron stamping, on the other hand, uses high-pressure presses to shape or cut sheet iron into precise components quickly, making it suitable for mass production of smaller, detailed parts. Key differences include extrusion's capability for continuous profiles and greater strength versus stamping's efficiency in producing complex, flat shapes with fine details.

Material Efficiency: Extrusion vs Stamping

Iron extrusion offers superior material efficiency compared to iron stamping by minimizing waste through continuous shaping, resulting in nearly 90-95% yield of the raw material. Iron stamping, involving cutting and shaping from flat sheets, typically generates 30-40% scrap material due to blanking and trimming processes. Optimizing extrusion can reduce raw iron consumption and lower production costs, making it more sustainable for high-volume manufacturing.

Cost Comparison: Iron Extrusion vs Iron Stamping

Iron extrusion typically incurs higher initial equipment costs due to the need for specialized dies and presses, but offers lower per-unit costs in large production runs because of material savings and reduced waste. Iron stamping demands less upfront investment, making it cost-effective for small to medium batch sizes, though tooling wear and material scrap can increase expenses over time. Choosing between iron extrusion and stamping hinges on production volume, with extrusion favored for high volumes and stamping better suited for lower quantities to optimize cost efficiency.

Design Flexibility and Complexity in Each Method

Iron extrusion offers enhanced design flexibility by allowing the creation of continuous, complex cross-sectional profiles with consistent mechanical properties, ideal for intricate shapes and long lengths. Iron stamping excels in producing high-volume, precise, and detailed parts with intricate surface features but is limited in complexity by die design and the thickness of the metal. The choice depends on the complexity of the design: extrusion suits elongated, uniform sections, while stamping handles detailed, flat or shallow parts efficiently.

Applications of Iron Extrusion vs Iron Stamping

Iron extrusion is widely used in manufacturing structural components, automotive parts, and architectural frameworks due to its ability to produce complex, continuous profiles with high strength and durability. Iron stamping is preferred for high-volume production of detailed parts such as brackets, enclosures, and automotive body panels, where precision and cost-efficiency are critical. Both processes serve distinct industrial applications, with extrusion favoring long, uniform shapes and stamping excelling in producing intricate, flat components.

Strength and Durability: Extruded vs Stamped Iron

Extruded iron exhibits superior strength and durability compared to stamped iron due to its continuous grain flow and uniform cross-section, which minimize weak points and enhance mechanical properties. Stamped iron, created under high pressure from sheet metal, may develop internal stresses and micro-cracks, reducing its long-term structural integrity. Applications requiring heavy load-bearing and resistance to fatigue often prefer extruded iron for its robustness and consistent performance.

Choosing the Right Process: Factors to Consider

Choosing between iron extrusion and iron stamping depends on factors such as desired part complexity, production volume, and material properties. Iron extrusion suits creating long, uniform cross-sections with excellent mechanical strength, while iron stamping is ideal for producing intricate shapes quickly in high volumes. Cost efficiency, precision requirements, and surface finish also influence the selection of the optimal iron forming process.

Iron Extrusion vs Iron Stamping Infographic

materialdif.com

materialdif.com