Iron annealing involves heating the metal to a specific temperature and allowing it to cool slowly, resulting in increased ductility and reduced hardness. Iron tempering, on the other hand, is a heat treatment process performed after quenching to reduce brittleness while maintaining adequate hardness and toughness. Both processes enhance the mechanical properties of iron but serve distinct purposes in metalworking and manufacturing.

Table of Comparison

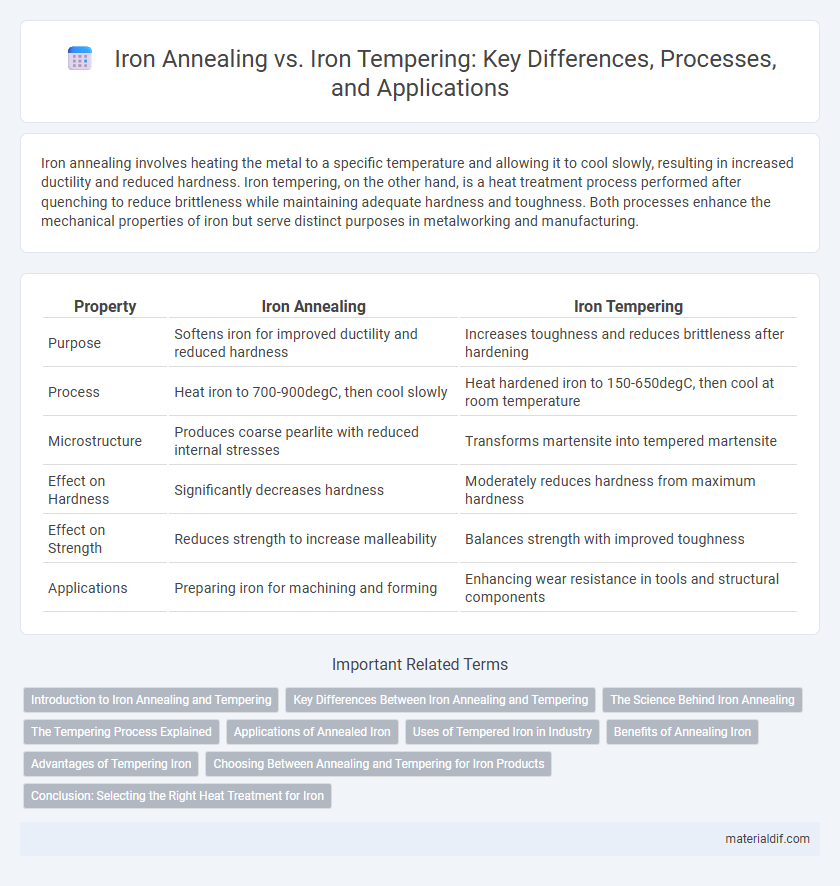

| Property | Iron Annealing | Iron Tempering |

|---|---|---|

| Purpose | Softens iron for improved ductility and reduced hardness | Increases toughness and reduces brittleness after hardening |

| Process | Heat iron to 700-900degC, then cool slowly | Heat hardened iron to 150-650degC, then cool at room temperature |

| Microstructure | Produces coarse pearlite with reduced internal stresses | Transforms martensite into tempered martensite |

| Effect on Hardness | Significantly decreases hardness | Moderately reduces hardness from maximum hardness |

| Effect on Strength | Reduces strength to increase malleability | Balances strength with improved toughness |

| Applications | Preparing iron for machining and forming | Enhancing wear resistance in tools and structural components |

Introduction to Iron Annealing and Tempering

Iron annealing involves heating the metal to a specific temperature and then cooling it slowly to soften the iron, improve its ductility, and relieve internal stresses. Tempering follows quenching, where the iron is reheated to a lower temperature and then cooled to reduce brittleness while maintaining hardness and strength. Both processes are essential heat treatments that tailor the mechanical properties of iron for various industrial applications.

Key Differences Between Iron Annealing and Tempering

Iron annealing involves heating the metal to a specific temperature and then cooling it slowly to soften the material, relieve internal stresses, and improve ductility. In contrast, iron tempering heats the metal below its critical point followed by controlled cooling to increase toughness and reduce brittleness without significantly softening the iron. Key differences include the temperature ranges used, cooling methods, and resulting mechanical properties such as hardness, strength, and flexibility.

The Science Behind Iron Annealing

Iron annealing involves heating the metal to a specific temperature, typically between 650degC and 700degC, and then allowing it to cool slowly to alter its microstructure, reducing hardness and increasing ductility. This process promotes the formation of pearlite and ferrite phases, relieving internal stresses and enhancing machinability. In contrast, iron tempering reheats quenched iron below its critical temperature to fine-tune hardness and toughness without significantly changing its microstructure.

The Tempering Process Explained

The tempering process involves heating iron to a temperature below its critical point, typically between 150degC and 650degC, then cooling it slowly to reduce brittleness while maintaining hardness. This controlled heat treatment alters the microstructure by relieving internal stresses and promoting the formation of tempered martensite, enhancing toughness and ductility. Compared to annealing, tempering produces a balance of strength and flexibility crucial for tools and machinery components.

Applications of Annealed Iron

Annealed iron exhibits enhanced ductility and reduced hardness, making it ideal for applications requiring extensive metal shaping, such as automotive components, structural frameworks, and intricate metalworking. The annealing process improves machinability and minimizes brittleness, allowing for precision fabrication in manufacturing equipment and tools. This softness also promotes superior electrical conductivity and corrosion resistance in electrical and architectural uses.

Uses of Tempered Iron in Industry

Tempered iron is widely used in industries requiring enhanced toughness and wear resistance, such as automotive manufacturing for gears, crankshafts, and suspension components. Its improved mechanical properties make it ideal for heavy machinery parts, tools, and structural applications where durability under stress is critical. The tempering process optimizes iron's hardness while maintaining flexibility, ensuring longer service life and reliability in industrial environments.

Benefits of Annealing Iron

Annealing iron improves its ductility and reduces internal stresses, making the metal more workable and less brittle during machining or forging processes. This heat treatment process refines the grain structure, resulting in enhanced toughness and a uniform microstructure. Compared to tempering, annealing offers superior benefits in restoring iron's softness and improving its malleability for subsequent fabrication steps.

Advantages of Tempering Iron

Tempering iron enhances its toughness and reduces brittleness by carefully reheating and cooling the metal after hardening, resulting in improved durability and resistance to cracking. This process refines the internal microstructure, balancing hardness with flexibility, which is crucial for applications requiring both strength and resilience. Compared to annealing, tempering provides superior mechanical properties that extend the lifespan of iron tools and components under stress.

Choosing Between Annealing and Tempering for Iron Products

Choosing between annealing and tempering for iron products depends on the desired mechanical properties and application requirements. Annealing softens iron by heating it to a specific temperature and cooling it slowly, improving ductility and reducing hardness, ideal for machining and forming processes. Tempering, performed after quenching, enhances toughness by reducing brittleness while maintaining hardness, making it suitable for tools and structural components needing impact resistance.

Conclusion: Selecting the Right Heat Treatment for Iron

Iron annealing enhances ductility and reduces hardness by heating the metal to a specific temperature and allowing it to cool slowly, making it ideal for shaping and machining processes. Iron tempering, performed by reheating quenched iron to a lower temperature, balances hardness and toughness, improving resistance to impact and wear. Selecting the right heat treatment depends on the desired mechanical properties and application requirements, with annealing suited for malleability and tempering for strength and durability.

Iron Annealing vs Iron Tempering Infographic

materialdif.com

materialdif.com