Powder metallurgy offers superior control over the particle size and composition of iron, resulting in enhanced mechanical properties and reduced waste compared to traditional smelting. Unlike traditional smelting, which involves melting and refining iron ore at high temperatures, powder metallurgy compacts and sinters iron powders, allowing for precise microstructural engineering. This method also enables complex shapes to be produced with minimal machining and energy consumption, making it a more efficient and environmentally friendly alternative.

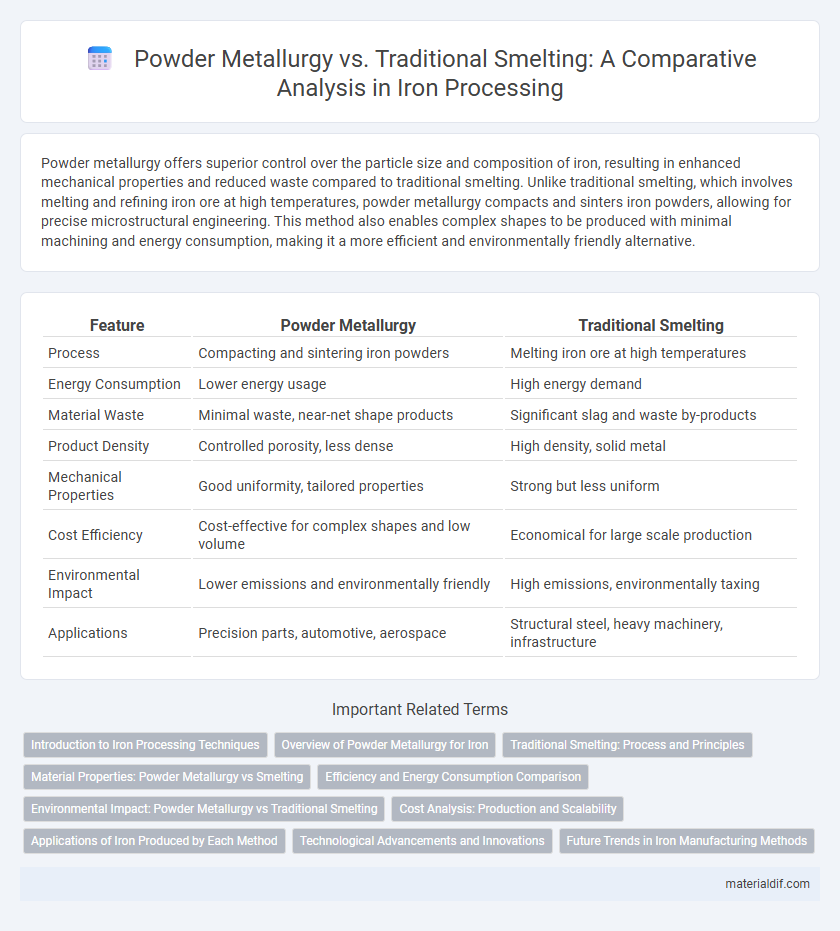

Table of Comparison

| Feature | Powder Metallurgy | Traditional Smelting |

|---|---|---|

| Process | Compacting and sintering iron powders | Melting iron ore at high temperatures |

| Energy Consumption | Lower energy usage | High energy demand |

| Material Waste | Minimal waste, near-net shape products | Significant slag and waste by-products |

| Product Density | Controlled porosity, less dense | High density, solid metal |

| Mechanical Properties | Good uniformity, tailored properties | Strong but less uniform |

| Cost Efficiency | Cost-effective for complex shapes and low volume | Economical for large scale production |

| Environmental Impact | Lower emissions and environmentally friendly | High emissions, environmentally taxing |

| Applications | Precision parts, automotive, aerospace | Structural steel, heavy machinery, infrastructure |

Introduction to Iron Processing Techniques

Powder metallurgy offers precise control over iron particle size and composition, enabling the production of complex shapes with minimal waste compared to traditional smelting, which relies on high-temperature reduction of iron ore to extract pure iron. Traditional smelting processes, such as blast furnace operation, produce large volumes of molten iron but involve significant energy consumption and emissions. Advances in powder metallurgy provide energy-efficient alternatives that enhance material properties and reduce environmental impact in iron processing techniques.

Overview of Powder Metallurgy for Iron

Powder metallurgy for iron involves compacting fine iron powders into desired shapes followed by sintering at high temperatures to create dense, near-net-shape components with superior mechanical properties. This process offers precise control over microstructure and composition, reducing material waste and energy consumption compared to traditional smelting. Powder metallurgy enables production of complex geometries and enhances material uniformity, making it ideal for high-performance industrial applications.

Traditional Smelting: Process and Principles

Traditional smelting of iron involves heating iron ore in a blast furnace to extract pure iron by reducing the ore with coke at high temperatures, typically around 1500degC. The process relies on chemical reactions where carbon monoxide reduces iron oxides to molten iron, separating impurities as slag. This method produces large quantities of iron but requires significant energy and raw materials compared to powder metallurgy techniques.

Material Properties: Powder Metallurgy vs Smelting

Powder metallurgy iron exhibits superior homogeneity and finer microstructure compared to traditionally smelted iron, resulting in enhanced mechanical properties such as increased tensile strength and wear resistance. The controlled particle size distribution in powder metallurgy allows for precise alloy composition and improved density, minimizing porosity typically found in smelted iron. Unlike smelting, which often leads to coarse grain formation and irregular impurities, powder metallurgy produces iron components with consistent hardness and better fatigue performance.

Efficiency and Energy Consumption Comparison

Powder metallurgy of iron offers superior efficiency by minimizing material waste and enabling near-net shape manufacturing, reducing the need for extensive machining compared to traditional smelting, which involves higher material loss through slag and scale formation. Energy consumption in powder metallurgy is lower due to the elimination of large-scale melting processes, relying instead on compacting and sintering at comparatively reduced temperatures. In contrast, traditional smelting demands substantial energy input to extract iron from ore via blast furnaces, resulting in higher carbon emissions and increased operational costs.

Environmental Impact: Powder Metallurgy vs Traditional Smelting

Powder metallurgy significantly reduces environmental impact compared to traditional smelting by minimizing energy consumption and lowering greenhouse gas emissions. Unlike traditional smelting, which releases large volumes of carbon dioxide and pollutants from ore reduction at high temperatures, powder metallurgy processes iron powders with less intensive heating and limited waste generation. This method also decreases the need for extensive raw material processing, resulting in less mining and reduced environmental degradation.

Cost Analysis: Production and Scalability

Powder metallurgy offers lower production costs for complex iron components by minimizing material waste and reducing machining time compared to traditional smelting, which requires extensive casting and forging processes. Scalability in powder metallurgy is advantageous for small- to medium-volume production runs due to its automated and energy-efficient processes, whereas traditional smelting benefits from economies of scale at large production volumes despite higher initial capital investment. The overall cost efficiency of powder metallurgy improves with the ability to produce near-net-shape parts, reducing downstream processing expenses significantly in iron manufacturing.

Applications of Iron Produced by Each Method

Iron produced via powder metallurgy excels in applications requiring precise mechanical properties and complex shapes, such as automotive components, aerospace parts, and medical implants. Traditional smelting iron is predominantly used in heavy industries like construction, shipbuilding, and machinery manufacturing due to its bulk production capacity and structural strength. Each method's iron serves distinct industrial sectors based on the material's density, porosity, and production scale.

Technological Advancements and Innovations

Powder metallurgy leverages advanced atomization and sintering technologies to produce iron components with precise control over microstructure and enhanced mechanical properties, surpassing traditional smelting in efficiency and material utilization. Innovations such as nanoscale powder production and additive manufacturing integration enable complex geometries and reduced waste, which conventional smelting methods cannot achieve. These technological advancements in powder metallurgy contribute to energy savings, improved product consistency, and sustainable iron manufacturing processes.

Future Trends in Iron Manufacturing Methods

Powder metallurgy is emerging as a key future trend in iron manufacturing due to its ability to produce complex shapes with minimal waste and superior material properties compared to traditional smelting. Advances in additive manufacturing and precise powder processing techniques enhance the efficiency and sustainability of iron production, reducing energy consumption and environmental impact. Research in nanoscale powder refinement and alloy development promises to optimize iron components for automotive and aerospace industries, driving innovation beyond the limitations of conventional smelting methods.

Powder Metallurgy vs Traditional Smelting Infographic

materialdif.com

materialdif.com