Forged iron is produced by heating and hammering iron into shape, resulting in a dense, strong material with enhanced toughness and durability. Cast iron is made by melting iron and pouring it into molds, which creates a brittle but hard and wear-resistant product suitable for heavy-duty applications. The choice between forged and cast iron depends on the need for tensile strength versus compressive strength and resistance to impact.

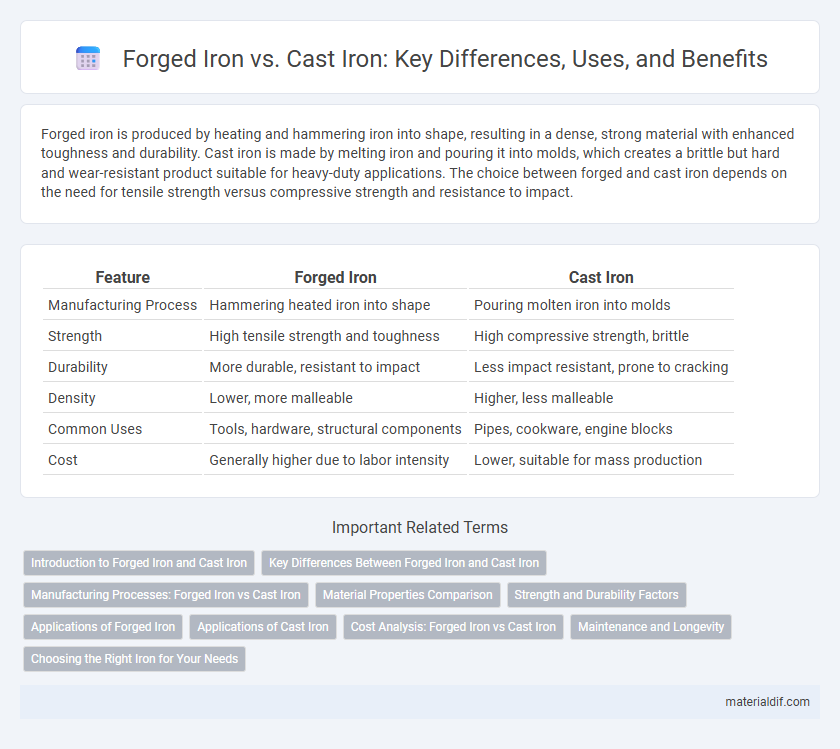

Table of Comparison

| Feature | Forged Iron | Cast Iron |

|---|---|---|

| Manufacturing Process | Hammering heated iron into shape | Pouring molten iron into molds |

| Strength | High tensile strength and toughness | High compressive strength, brittle |

| Durability | More durable, resistant to impact | Less impact resistant, prone to cracking |

| Density | Lower, more malleable | Higher, less malleable |

| Common Uses | Tools, hardware, structural components | Pipes, cookware, engine blocks |

| Cost | Generally higher due to labor intensity | Lower, suitable for mass production |

Introduction to Forged Iron and Cast Iron

Forged iron is created by heating and hammering iron into shape, resulting in a dense, strong, and malleable material often used in tools and decorative items due to its superior toughness. Cast iron, produced by pouring molten iron into molds, is characterized by its excellent compressive strength, high carbon content, and brittleness, making it ideal for cookware, pipes, and machinery parts. The fundamental difference lies in the manufacturing process, where forging improves grain structure and durability, while casting allows for complex shapes but produces a more brittle final product.

Key Differences Between Forged Iron and Cast Iron

Forged iron is produced by heating and hammering metal, resulting in a denser and stronger material with enhanced malleability and toughness, ideal for tools and high-stress applications. Cast iron is made by melting iron and pouring it into molds, yielding a brittle but hard material with excellent compressive strength, commonly used in pipes, cookware, and machinery parts. The key differences lie in their manufacturing processes, structural properties, and applications, with forged iron offering superior tensile strength and ductility compared to the more brittle and castable nature of cast iron.

Manufacturing Processes: Forged Iron vs Cast Iron

Forged iron is produced through a hot working process where heated iron is hammered or pressed into shape, resulting in a denser and more durable material with aligned grain structures. Cast iron is created by melting iron and pouring it into molds, allowing for complex shapes but often producing a more brittle and porous final product due to rapid cooling. The manufacturing process of forged iron enhances its tensile strength and ductility, whereas cast iron's process favors intricate design with reduced mechanical resilience.

Material Properties Comparison

Forged iron exhibits superior tensile strength and ductility due to its refined grain structure achieved through hammering or pressing, making it ideal for high-stress applications. Cast iron, characterized by its high carbon content and brittle nature, offers excellent compressive strength and wear resistance but is prone to cracking under tension. The microstructural differences result in forged iron being more malleable and impact-resistant, whereas cast iron provides enhanced rigidity and thermal conductivity.

Strength and Durability Factors

Forged iron exhibits superior strength and durability due to its manufacturing process, which involves hammering and shaping the metal while hot, aligning its grain structure and reducing internal defects. Cast iron, created by pouring molten metal into molds, tends to be more brittle and less impact-resistant because of its higher carbon content and coarse microstructure. The enhanced toughness and fatigue resistance of forged iron make it ideal for applications requiring robust mechanical performance.

Applications of Forged Iron

Forged iron exhibits superior strength and durability due to its dense grain structure, making it ideal for high-stress applications such as automotive components, industrial machinery, and tool manufacturing. Its enhanced toughness and resistance to impact allow forged iron to perform reliably under dynamic loads and harsh operating conditions. The material's ability to maintain structural integrity under heavy fatigue cycles positions it as a preferred choice in critical engineering applications.

Applications of Cast Iron

Cast iron's high compressive strength and excellent wear resistance make it ideal for heavy-duty applications such as engine blocks, pipes, and cookware. Its ability to absorb vibrations and retain heat is widely utilized in machinery bases and stoves, improving operational stability and efficiency. The material's affordability and ease of casting complex shapes drive its extensive use in automotive components and infrastructure projects.

Cost Analysis: Forged Iron vs Cast Iron

Forged iron typically incurs higher production costs due to the labor-intensive shaping process and the need for specialized equipment, which results in superior strength and durability. Cast iron offers a more cost-effective option because it is produced by pouring molten iron into molds, enabling mass production with lower material and manufacturing expenses. Evaluating long-term value, forged iron's enhanced mechanical properties often justify its initial higher cost in applications requiring toughness and impact resistance.

Maintenance and Longevity

Forged iron exhibits superior durability and easier maintenance due to its dense grain structure, which resists cracking and corrosion over time, making it ideal for items requiring high strength and longevity. Cast iron, while heavier and more brittle, demands regular seasoning and careful handling to prevent rust and chipping, which can limit its lifespan if neglected. Choosing forged iron provides longer-lasting performance with less frequent upkeep compared to cast iron's vulnerability to surface damage and maintenance needs.

Choosing the Right Iron for Your Needs

Forged iron offers superior strength and durability due to its manufacturing process, making it ideal for tools and structural components requiring high impact resistance. Cast iron provides excellent heat retention and is better suited for cookware and decorative items where complex shapes are needed. Selecting between forged and cast iron depends on prioritizing mechanical strength versus heat distribution and design flexibility.

Forged Iron vs Cast Iron Infographic

materialdif.com

materialdif.com