Pig iron is the crude form of iron produced from smelting iron ore in a blast furnace, containing high carbon content and impurities that make it brittle and unsuitable for most applications. Steel iron is an alloy derived from pig iron through refining processes that reduce carbon content and add elements like manganese, improving strength, ductility, and corrosion resistance. The transformation from pig iron to steel iron enables versatile uses in construction, manufacturing, and automotive industries due to enhanced mechanical properties.

Table of Comparison

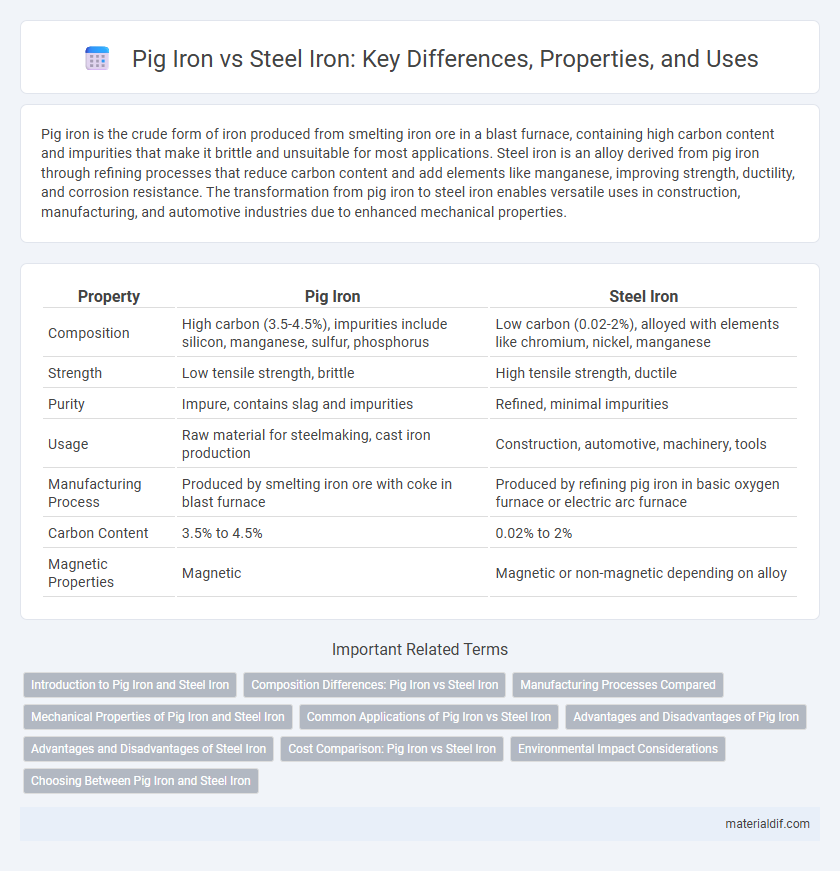

| Property | Pig Iron | Steel Iron |

|---|---|---|

| Composition | High carbon (3.5-4.5%), impurities include silicon, manganese, sulfur, phosphorus | Low carbon (0.02-2%), alloyed with elements like chromium, nickel, manganese |

| Strength | Low tensile strength, brittle | High tensile strength, ductile |

| Purity | Impure, contains slag and impurities | Refined, minimal impurities |

| Usage | Raw material for steelmaking, cast iron production | Construction, automotive, machinery, tools |

| Manufacturing Process | Produced by smelting iron ore with coke in blast furnace | Produced by refining pig iron in basic oxygen furnace or electric arc furnace |

| Carbon Content | 3.5% to 4.5% | 0.02% to 2% |

| Magnetic Properties | Magnetic | Magnetic or non-magnetic depending on alloy |

Introduction to Pig Iron and Steel Iron

Pig iron, a crude form of iron produced by smelting iron ore in a blast furnace, contains high carbon content, typically 3.5-4.5%, making it brittle and unsuitable for direct use in construction. Steel iron, derived from pig iron through refining processes such as basic oxygen steelmaking, has controlled carbon levels usually below 2%, providing enhanced strength, flexibility, and corrosion resistance. Understanding the distinction between pig iron and steel iron is crucial for applications in manufacturing, construction, and industrial engineering.

Composition Differences: Pig Iron vs Steel Iron

Pig iron contains about 3.5-4.5% carbon, along with silicon, manganese, sulfur, and phosphorus impurities, making it brittle and unsuitable for structural use. Steel iron typically has a reduced carbon content, usually below 2%, and controlled amounts of alloying elements such as chromium, nickel, and molybdenum to improve strength and ductility. The critical difference lies in the carbon concentration and impurity levels, where steel undergoes refining processes to achieve desired mechanical properties.

Manufacturing Processes Compared

Pig iron is produced by smelting iron ore with a high-carbon fuel such as coke, using a blast furnace that yields a brittle, high-carbon content metal with impurities like sulfur and phosphorus. Steel iron undergoes further refinement through processes such as basic oxygen steelmaking or electric arc furnace methods, which reduce carbon content and remove impurities to produce a more ductile and stronger alloy. The key difference in manufacturing lies in the additional alloying and purification steps for steel to optimize mechanical properties and corrosion resistance compared to the raw, less purified pig iron.

Mechanical Properties of Pig Iron and Steel Iron

Pig iron exhibits high carbon content, typically 3.5-4.5%, resulting in brittleness and low tensile strength, making it unsuitable for structural applications. Steel iron, with carbon content less than 2%, demonstrates improved mechanical properties such as greater ductility, tensile strength, and toughness due to controlled carbon and alloying elements. The microstructure differences significantly influence hardness and machinability, where steel iron's balanced composition offers superior performance in construction and manufacturing industries.

Common Applications of Pig Iron vs Steel Iron

Pig iron is primarily used as a raw material in the production of steel, cast iron, and various iron-based alloys, serving as a critical intermediate in foundries and steel mills. Steel iron, known for its enhanced strength and ductility, finds extensive applications in construction, automotive manufacturing, machinery, and infrastructure projects due to its durability and versatility. The superior mechanical properties of steel iron make it the preferred choice for tools, structural components, and heavy-duty equipment, whereas pig iron's higher carbon content limits its direct applications mainly to further refining and alloying processes.

Advantages and Disadvantages of Pig Iron

Pig iron contains a high carbon content, making it brittle and unsuitable for direct use in construction, but it serves as a crucial intermediate product in steel manufacturing due to its ease of production from iron ore in blast furnaces. The primary advantage of pig iron lies in its cost-effectiveness and efficiency as a raw material for producing various steel grades through further processing. However, the disadvantages include its low malleability, hardness, and tendency to fracture, limiting its applicability without refining into steel.

Advantages and Disadvantages of Steel Iron

Steel iron offers higher tensile strength and improved corrosion resistance compared to pig iron, making it ideal for construction and manufacturing applications. Its alloying elements, such as carbon, manganese, and chromium, enhance durability but increase production costs and complexity. The trade-off includes better weldability and machinability against susceptibility to brittleness if improperly treated.

Cost Comparison: Pig Iron vs Steel Iron

Pig iron typically costs less than steel iron due to its lower processing requirements and higher impurity levels. Steel iron demands more refining and alloying treatments, increasing production expenses compared to pig iron. The price difference reflects steel's superior strength and versatility, justifying its higher cost for industrial applications.

Environmental Impact Considerations

Pig iron production releases higher amounts of carbon dioxide and other pollutants due to its energy-intensive smelting process, contributing significantly to air pollution and climate change. Steel iron, especially when produced using recycled scrap and electric arc furnaces, offers a lower environmental footprint by reducing raw material extraction and energy consumption. Emphasizing energy efficiency and recycling in steel iron manufacturing plays a crucial role in minimizing greenhouse gas emissions and conserving natural resources.

Choosing Between Pig Iron and Steel Iron

Choosing between pig iron and steel iron depends on the desired material properties and end-use applications. Pig iron, with its high carbon content (typically 3.5-4.5%), is brittle and primarily used as a raw material for producing steel and cast iron. Steel iron, characterized by lower carbon content (usually less than 2%) and added alloying elements, offers superior strength, ductility, and corrosion resistance, making it suitable for construction, automotive, and machinery industries.

Pig Iron vs Steel Iron Infographic

materialdif.com

materialdif.com