Galvanized iron offers robust corrosion resistance through a protective zinc coating, making it ideal for outdoor applications exposed to moisture. Stainless iron, an alloy containing chromium, provides superior durability and rust resistance without the need for additional coatings, perfect for environments demanding long-term strength and hygiene. Choosing between galvanized and stainless iron depends on the specific requirements for corrosion protection, maintenance, and cost-effectiveness.

Table of Comparison

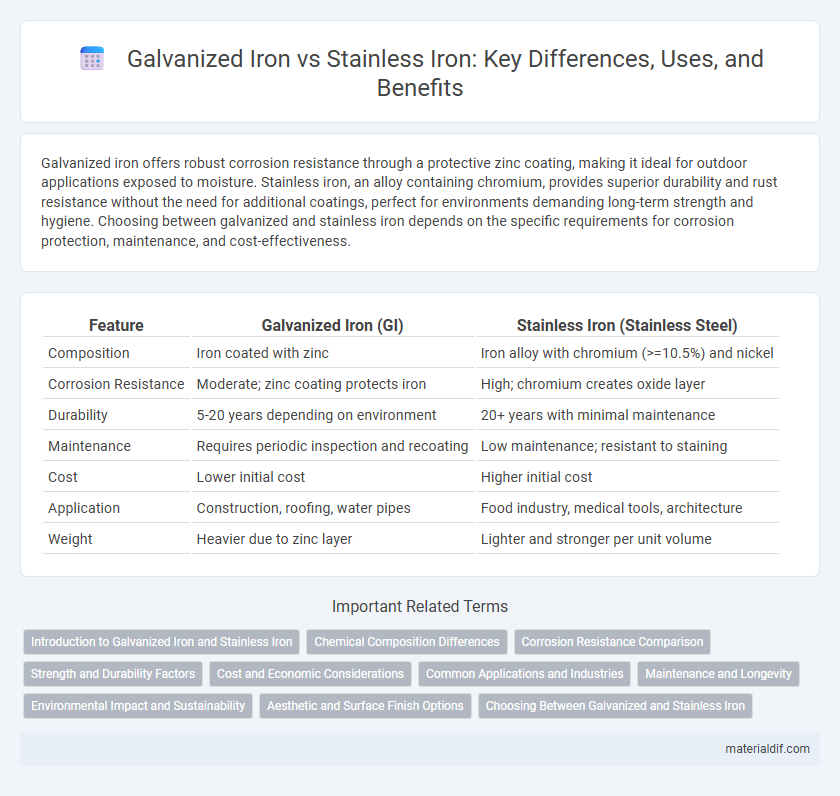

| Feature | Galvanized Iron (GI) | Stainless Iron (Stainless Steel) |

|---|---|---|

| Composition | Iron coated with zinc | Iron alloy with chromium (>=10.5%) and nickel |

| Corrosion Resistance | Moderate; zinc coating protects iron | High; chromium creates oxide layer |

| Durability | 5-20 years depending on environment | 20+ years with minimal maintenance |

| Maintenance | Requires periodic inspection and recoating | Low maintenance; resistant to staining |

| Cost | Lower initial cost | Higher initial cost |

| Application | Construction, roofing, water pipes | Food industry, medical tools, architecture |

| Weight | Heavier due to zinc layer | Lighter and stronger per unit volume |

Introduction to Galvanized Iron and Stainless Iron

Galvanized iron is steel coated with a layer of zinc to protect it from corrosion, making it ideal for outdoor and industrial applications. Stainless iron, commonly referred to as stainless steel, is an alloy containing chromium and nickel, providing exceptional resistance to rust and staining. Both materials offer durability, but galvanized iron prioritizes corrosion prevention through zinc coating, whereas stainless iron relies on its alloy composition for longevity.

Chemical Composition Differences

Galvanized iron consists of a carbon steel core coated in zinc to prevent rusting, typically containing 0.1-0.3% carbon along with trace elements such as manganese and phosphorus. Stainless iron, austenitic or ferritic stainless steel, includes at least 10.5% chromium which forms a passive oxide layer, and may contain varying amounts of nickel, molybdenum, and carbon below 0.08% to enhance corrosion resistance and strength. The primary chemical difference lies in the zinc coating of galvanized iron versus the chromium-rich alloy composition of stainless iron that inherently resists oxidation.

Corrosion Resistance Comparison

Galvanized iron features a zinc coating that provides strong corrosion resistance by acting as a sacrificial anode, protecting the underlying metal from rust. Stainless iron, containing a high percentage of chromium (typically 10-30%), forms a passive oxide layer that offers superior and long-lasting corrosion resistance in harsh environments. While galvanized iron is ideal for outdoor and industrial applications with moderate exposure, stainless iron excels in chemical, marine, and high-moisture settings due to its enhanced durability against corrosion.

Strength and Durability Factors

Galvanized iron offers enhanced corrosion resistance due to its zinc coating, making it ideal for outdoor and humid environments where rust prevention is critical. Stainless iron, composed primarily of iron alloyed with chromium and nickel, provides superior strength and exceptional durability against oxidation, sustaining structural integrity under extreme conditions. The choice between galvanized and stainless iron depends on the balance of toughness, environmental exposure, and longevity requirements for construction or industrial applications.

Cost and Economic Considerations

Galvanized iron generally costs less upfront due to its zinc coating process that prevents rust and extends product lifespan, making it economical for budget-sensitive projects requiring corrosion resistance. Stainless iron, alloyed with chromium and nickel, carries a higher initial price but offers superior durability, reducing long-term maintenance and replacement expenses. Choosing between galvanized and stainless iron depends on the specific application's exposure to corrosive environments and the total cost of ownership over time.

Common Applications and Industries

Galvanized iron is extensively used in construction, automotive, and agriculture industries due to its corrosion resistance and cost-effectiveness, making it ideal for roofing, fencing, and water pipes. Stainless iron, known for its durability and resistance to rust and staining, is preferred in food processing, pharmaceutical, and chemical industries where hygiene and strength are critical. Both materials serve distinct roles, with galvanized iron dominating outdoor applications and stainless iron excelling in environments requiring high corrosion resistance and cleanliness.

Maintenance and Longevity

Galvanized iron offers excellent corrosion resistance due to its zinc coating, reducing maintenance needs and extending lifespan in outdoor or moist environments. Stainless iron, composed primarily of iron, chromium, and nickel, provides superior rust prevention with minimal upkeep, making it ideal for harsh or corrosive settings. Both materials boast long-term durability, but stainless iron generally requires less frequent maintenance, resulting in higher longevity over time.

Environmental Impact and Sustainability

Galvanized iron, coated with zinc to prevent corrosion, has a higher environmental footprint due to zinc mining and coating processes emitting greenhouse gases and generating hazardous waste. Stainless iron, primarily composed of iron, chromium, and nickel, offers greater durability and recyclability, reducing the need for frequent replacements and lowering its overall environmental impact. Choosing stainless iron supports sustainability efforts by minimizing resource extraction, improving lifecycle longevity, and enhancing recyclability compared to galvanized iron.

Aesthetic and Surface Finish Options

Galvanized iron offers a matte, rugged surface finish with a characteristic spangled pattern due to its zinc coating, providing robust corrosion resistance ideal for industrial and outdoor applications. Stainless iron, primarily referring to stainless steel, boasts a sleek, polished aesthetic available in various finishes such as brushed, mirror, and satin that enhance its visual appeal for architectural and decorative purposes. The surface finish options of stainless iron allow for greater customization with superior stain and rust resistance, making it preferred where both aesthetics and durability are critical.

Choosing Between Galvanized and Stainless Iron

Choosing between galvanized iron and stainless iron depends on exposure to environmental factors and maintenance requirements. Galvanized iron offers robust corrosion resistance through a zinc coating, ideal for outdoor or industrial applications, while stainless iron, composed of iron alloys with chromium, provides superior durability and rust resistance without additional coatings, suitable for high-humidity or chemical environments. Cost-effectiveness and longevity should be balanced against the specific use case, with galvanized iron generally more affordable and stainless iron offering extended lifespan and minimal upkeep.

Galvanized Iron vs Stainless Iron Infographic

materialdif.com

materialdif.com