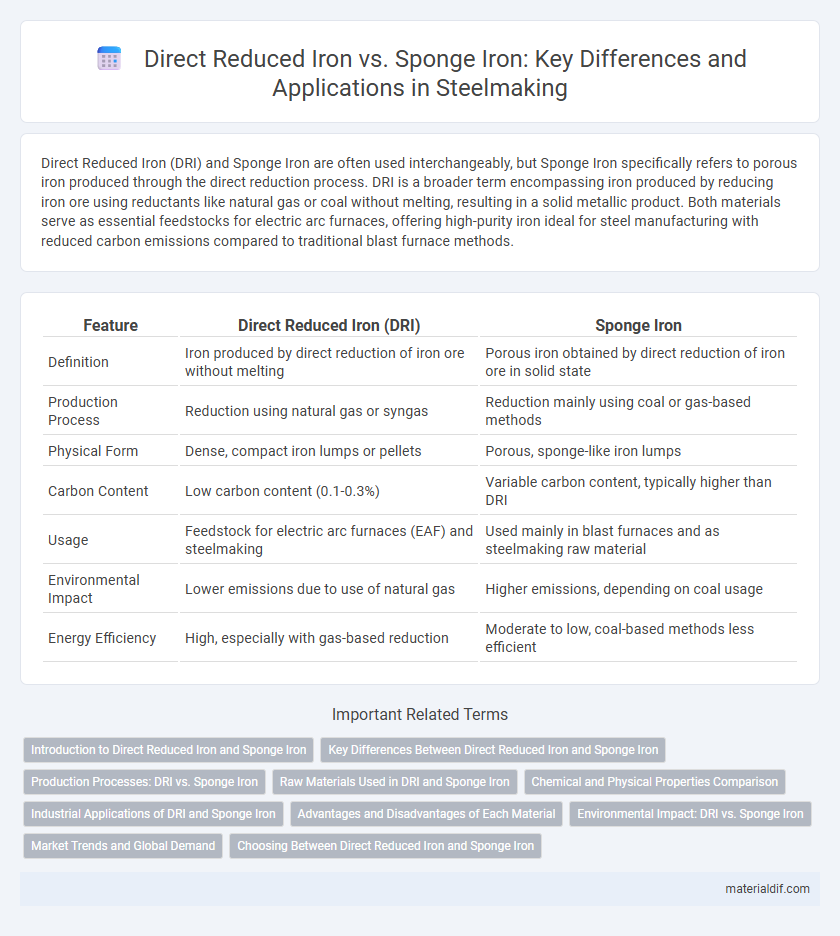

Direct Reduced Iron (DRI) and Sponge Iron are often used interchangeably, but Sponge Iron specifically refers to porous iron produced through the direct reduction process. DRI is a broader term encompassing iron produced by reducing iron ore using reductants like natural gas or coal without melting, resulting in a solid metallic product. Both materials serve as essential feedstocks for electric arc furnaces, offering high-purity iron ideal for steel manufacturing with reduced carbon emissions compared to traditional blast furnace methods.

Table of Comparison

| Feature | Direct Reduced Iron (DRI) | Sponge Iron |

|---|---|---|

| Definition | Iron produced by direct reduction of iron ore without melting | Porous iron obtained by direct reduction of iron ore in solid state |

| Production Process | Reduction using natural gas or syngas | Reduction mainly using coal or gas-based methods |

| Physical Form | Dense, compact iron lumps or pellets | Porous, sponge-like iron lumps |

| Carbon Content | Low carbon content (0.1-0.3%) | Variable carbon content, typically higher than DRI |

| Usage | Feedstock for electric arc furnaces (EAF) and steelmaking | Used mainly in blast furnaces and as steelmaking raw material |

| Environmental Impact | Lower emissions due to use of natural gas | Higher emissions, depending on coal usage |

| Energy Efficiency | High, especially with gas-based reduction | Moderate to low, coal-based methods less efficient |

Introduction to Direct Reduced Iron and Sponge Iron

Direct Reduced Iron (DRI) and Sponge Iron are both forms of iron produced by reducing iron ore in solid state without melting. DRI typically results from a reduction process using natural gas or coal-based methods, producing highly pure iron pellets with low residual carbon. Sponge Iron, often synonymous with DRI, is characterized by its porous, sponge-like texture formed after the reduction, which facilitates its use in electric arc furnace steelmaking.

Key Differences Between Direct Reduced Iron and Sponge Iron

Direct Reduced Iron (DRI) and Sponge Iron are often used interchangeably but differ mainly in production processes and physical properties; DRI is produced through a solid-state reduction of iron ore pellets or lumps using a reducing gas, while Sponge Iron results from direct reduction in solid form, retaining a porous, sponge-like structure. DRI typically has higher iron content and fewer impurities, making it more suitable for electric arc furnace steelmaking, whereas Sponge Iron may have higher residual gangue materials and varying metallization levels. Understanding these distinctions impacts their application in steel production and affects efficiency, product quality, and cost-effectiveness in metallurgy.

Production Processes: DRI vs. Sponge Iron

Direct Reduced Iron (DRI) is produced through the reduction of iron ore in solid-state using a reducing gas mixture of hydrogen and carbon monoxide, preserving the iron's metallic form without melting. Sponge Iron results from a similar solid-state reduction process but often emphasizes the porous, sponge-like structure formed as iron ore is reduced at lower temperatures. Both processes aim to produce high-purity iron suitable for steelmaking, but DRI prioritizes gas-based reduction while sponge iron production may include coal-based methods, affecting the final porosity and carbon content.

Raw Materials Used in DRI and Sponge Iron

Direct Reduced Iron (DRI) primarily uses iron ore pellets or lump iron ore combined with natural gas or coal as reducing agents, ensuring a high-quality iron product with low carbon content. Sponge iron, produced similarly, often utilizes iron ore fines and non-coking coal or charcoal, which can result in varying carbon content depending on the raw material purity. The choice of raw materials in both DRI and sponge iron production directly impacts the metallurgical properties and suitability for steelmaking processes.

Chemical and Physical Properties Comparison

Direct Reduced Iron (DRI) and Sponge Iron differ primarily in their chemical purity and physical structure; DRI exhibits higher metallic iron content, typically above 90%, with lower levels of impurities such as sulfur and phosphorus, enhancing its suitability for steelmaking. Physically, DRI has a dense, solid metallic form, whereas Sponge Iron features a porous, sponge-like texture resulting from its production process via reduction of iron ore in solid state. The higher density and lower impurity content in DRI contribute to improved melting efficiency and steel quality compared to Sponge Iron.

Industrial Applications of DRI and Sponge Iron

Direct Reduced Iron (DRI) and Sponge Iron are primarily used as high-quality feedstock in electric arc furnaces for steelmaking, offering lower impurities compared to scrap metal. Industrial applications of DRI focus on its efficiency in producing alloy steels and reducing carbon emissions during the steel production process. Sponge Iron, a less dense form of DRI, is favored in industries requiring a quick melting rate and is often used in foundries and as a raw material for manufacturing stainless steel.

Advantages and Disadvantages of Each Material

Direct Reduced Iron (DRI) offers high purity with low carbon content, making it ideal for electric arc furnace steelmaking and reducing the need for further refining; however, its production requires natural gas or other reducing gases, which can be costly and less accessible. Sponge Iron, a form of DRI characterized by its porous texture, provides efficient melting and is well-suited for scrap substitution, but it tends to be more brittle and susceptible to reoxidation during handling and storage. Both materials enhance steel quality by minimizing impurities compared to traditional scrap, yet their economic feasibility depends heavily on local raw material availability and energy costs.

Environmental Impact: DRI vs. Sponge Iron

Direct Reduced Iron (DRI) and Sponge Iron both contribute to iron production, but DRI generally exhibits a lower environmental footprint due to its efficient use of natural gas, resulting in reduced carbon dioxide emissions compared to the coal-based sponge iron process. Sponge Iron production often involves higher energy consumption and greater release of pollutants such as sulfur dioxide and particulate matter, negatively impacting air quality. By optimizing the DRI process with renewable energy inputs, steelmakers can significantly decrease greenhouse gas emissions and advance sustainable iron manufacturing.

Market Trends and Global Demand

Direct Reduced Iron (DRI) and Sponge Iron are key products in the iron market, with DRI use expanding due to its higher purity and suitability for electric arc furnaces in steelmaking. Market trends indicate growing demand for DRI in regions like the Middle East and India, driven by steel production growth and the shift toward environmentally sustainable processes. Global demand for Sponge Iron remains robust in developing economies, supported by cost-effective production methods and integration into primary steel manufacturing.

Choosing Between Direct Reduced Iron and Sponge Iron

Choosing between Direct Reduced Iron (DRI) and Sponge Iron depends on their production process and impurity levels; DRI is produced through a continuous gas-based reduction process yielding purer iron with lower carbon content, making it ideal for electric arc furnace steelmaking. Sponge Iron, often used interchangeably with DRI, can sometimes refer to iron with higher residual impurities due to solid fuel-based reduction, which may affect its suitability for certain steel grades. Evaluating the intended application, furnace type, and quality requirements helps in selecting the appropriate iron variant for efficient steel production.

Direct Reduced Iron vs Sponge Iron Infographic

materialdif.com

materialdif.com