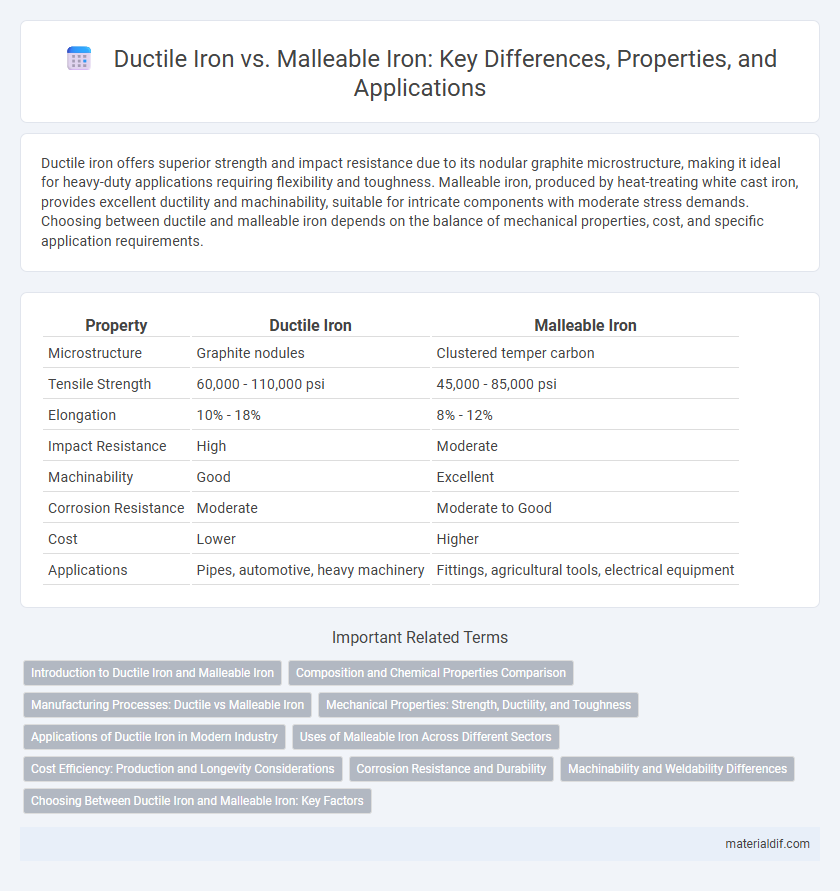

Ductile iron offers superior strength and impact resistance due to its nodular graphite microstructure, making it ideal for heavy-duty applications requiring flexibility and toughness. Malleable iron, produced by heat-treating white cast iron, provides excellent ductility and machinability, suitable for intricate components with moderate stress demands. Choosing between ductile and malleable iron depends on the balance of mechanical properties, cost, and specific application requirements.

Table of Comparison

| Property | Ductile Iron | Malleable Iron |

|---|---|---|

| Microstructure | Graphite nodules | Clustered temper carbon |

| Tensile Strength | 60,000 - 110,000 psi | 45,000 - 85,000 psi |

| Elongation | 10% - 18% | 8% - 12% |

| Impact Resistance | High | Moderate |

| Machinability | Good | Excellent |

| Corrosion Resistance | Moderate | Moderate to Good |

| Cost | Lower | Higher |

| Applications | Pipes, automotive, heavy machinery | Fittings, agricultural tools, electrical equipment |

Introduction to Ductile Iron and Malleable Iron

Ductile iron is a type of cast iron known for its enhanced ductility and tensile strength due to the formation of spherical graphite nodules within the iron matrix. Malleable iron, produced by heat-treating white cast iron, features temper carbon clusters that provide improved malleability and resistance to impact. Both materials serve distinct roles in industrial applications, with ductile iron preferred for components requiring high strength and flexibility, while malleable iron suits complex shapes needing good machinability and toughness.

Composition and Chemical Properties Comparison

Ductile iron contains spheroidal graphite particles that enhance its tensile strength and ductility, primarily composed of iron with 3-4% carbon, 1.7-3% silicon, and trace amounts of manganese, magnesium, and other elements. Malleable iron differs with its annealed structure consisting of temper carbon in nodular form, typically containing 2.5-3.5% carbon, 1.5-2.5% silicon, and small amounts of manganese and sulfur to improve malleability and toughness. The chemical composition variations directly influence their microstructures, resulting in ductile iron offering superior elongation and impact resistance compared to the more brittle, yet workable, malleable iron.

Manufacturing Processes: Ductile vs Malleable Iron

Ductile iron is produced through a spheroidizing process where magnesium or cerium is added to molten iron, creating graphite nodules that enhance toughness and ductility. Malleable iron undergoes prolonged annealing heat treatment to transform white iron into tempered carbon clusters, improving flexibility and impact resistance. The manufacturing difference results in ductile iron having superior tensile strength, while malleable iron offers better machinability for complex parts.

Mechanical Properties: Strength, Ductility, and Toughness

Ductile iron exhibits higher tensile strength, typically ranging from 60,000 to 120,000 psi, compared to malleable iron's 40,000 to 70,000 psi, making it suitable for applications requiring superior load-bearing capacity. Its ductility is enhanced by spheroidal graphite structures, providing elongation values between 10% and 20%, whereas malleable iron's tempering process results in similarly good but generally lower ductility around 8% to 15%. Toughness in ductile iron, driven by its microstructure, surpasses malleable iron, offering better resistance to impact and fatigue stresses, which ensures longer service life in dynamic conditions.

Applications of Ductile Iron in Modern Industry

Ductile iron is widely employed in modern industry for manufacturing automotive components, such as crankshafts and gears, due to its superior tensile strength and impact resistance. Applications extend to water and sewage pipes, where its corrosion resistance and durability improve infrastructure longevity. Its ability to withstand high pressure and mechanical stress makes it ideal for heavy-duty machinery parts and construction equipment frames.

Uses of Malleable Iron Across Different Sectors

Malleable iron is widely used in the construction, automotive, and agricultural sectors due to its excellent tensile strength and impact resistance. Its ability to withstand high stress makes it ideal for manufacturing pipe fittings, brackets, and heavy machinery components. The versatility of malleable iron enables it to perform effectively in applications requiring durability and flexibility in harsh environments.

Cost Efficiency: Production and Longevity Considerations

Ductile iron offers superior cost efficiency in production due to its faster casting process and reduced machining requirements compared to malleable iron. Its enhanced tensile strength and impact resistance contribute to longer service life, minimizing replacement frequencies and maintenance expenses. Malleable iron, while typically cheaper per pound, often incurs higher overall lifecycle costs due to increased brittleness and susceptibility to fatigue failures.

Corrosion Resistance and Durability

Ductile iron offers superior corrosion resistance due to its compact graphite nodules and dense microstructure, which reduces the likelihood of rust formation compared to malleable iron. Malleable iron, while strong and impact-resistant, tends to have lower corrosion resistance because of its irregular graphite clusters that can create localized weaknesses. The enhanced durability of ductile iron makes it ideal for harsh environments where prolonged exposure to moisture and chemicals occurs, ensuring longer service life.

Machinability and Weldability Differences

Ductile iron offers superior machinability due to its spherical graphite structure, which reduces tool wear and enhances cutting speed compared to malleable iron's irregular graphite shape. Malleable iron, while less machinable, provides better weldability with fewer risks of cracking or brittleness during heat treatment processes. The differences in graphite morphology directly influence mechanical properties, making ductile iron preferable for complex machining and malleable iron suitable for welded assemblies requiring toughness.

Choosing Between Ductile Iron and Malleable Iron: Key Factors

Ductile iron offers superior tensile strength and impact resistance due to its spherical graphite structure, making it ideal for high-stress applications like automotive components and heavy machinery. Malleable iron, characterized by its tempered carbon content and nodular graphite, provides excellent ductility and machinability, suited for intricate shapes and smaller parts such as pipe fittings and tools. Key factors in choosing between these two include load requirements, operating environment, and desired mechanical properties, with ductile iron favored for toughness and malleable iron preferred for flexibility and ease of fabrication.

Ductile Iron vs Malleable Iron Infographic

materialdif.com

materialdif.com