Galvanized iron is coated with a layer of zinc to protect it from rust and corrosion, making it ideal for outdoor and industrial applications. Mild iron, also known as mild steel, lacks this protective coating, resulting in lower resistance to environmental damage but greater malleability and ease of welding. Choosing between galvanized iron and mild iron depends on the specific needs for durability versus workability in construction or manufacturing projects.

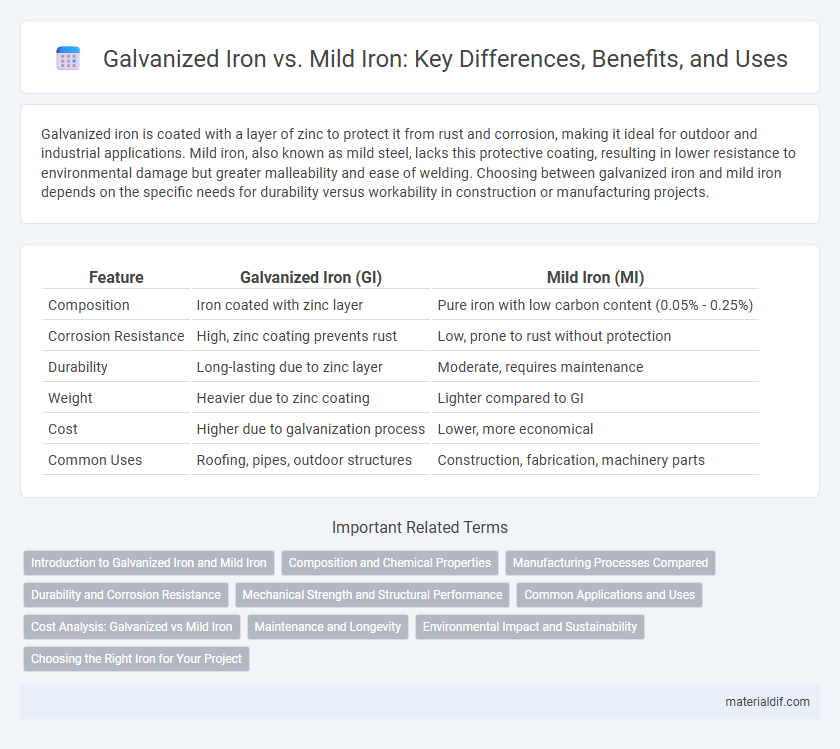

Table of Comparison

| Feature | Galvanized Iron (GI) | Mild Iron (MI) |

|---|---|---|

| Composition | Iron coated with zinc layer | Pure iron with low carbon content (0.05% - 0.25%) |

| Corrosion Resistance | High, zinc coating prevents rust | Low, prone to rust without protection |

| Durability | Long-lasting due to zinc layer | Moderate, requires maintenance |

| Weight | Heavier due to zinc coating | Lighter compared to GI |

| Cost | Higher due to galvanization process | Lower, more economical |

| Common Uses | Roofing, pipes, outdoor structures | Construction, fabrication, machinery parts |

Introduction to Galvanized Iron and Mild Iron

Galvanized iron is steel or iron coated with a protective layer of zinc to prevent rusting and enhance durability, making it ideal for outdoor and industrial applications. Mild iron, also known as mild steel, contains low carbon content, offering ductility, weldability, and moderate tensile strength for general construction and fabrication purposes. Understanding the structural differences between galvanized iron and mild iron helps in selecting the right material for corrosion resistance or mechanical performance.

Composition and Chemical Properties

Galvanized iron consists of mild steel coated with a layer of zinc to prevent corrosion, combining the ductility of mild iron with the corrosion resistance of zinc. Mild iron, primarily composed of iron with a carbon content of about 0.05%-0.25%, exhibits high malleability and tensile strength but lacks inherent resistance to rust. The zinc coating in galvanized iron undergoes sacrificial oxidation, forming a protective barrier that significantly enhances durability compared to untreated mild iron.

Manufacturing Processes Compared

Galvanized iron undergoes a manufacturing process where mild iron is coated with a layer of zinc through hot-dip galvanization or electro-galvanization, enhancing its corrosion resistance and durability. Mild iron, produced through the basic oxygen furnace or electric arc furnace methods, remains uncoated and more susceptible to rust in outdoor or humid environments. The zinc coating in galvanized iron provides superior protection against oxidation, extending the lifespan of structures and components compared to untreated mild iron.

Durability and Corrosion Resistance

Galvanized iron exhibits superior durability and corrosion resistance compared to mild iron due to its protective zinc coating that prevents rust formation. Mild iron, though strong and malleable, lacks this protective layer, making it more susceptible to corrosion when exposed to moisture and environmental elements. The zinc coating on galvanized iron extends its lifespan significantly, especially in outdoor and industrial applications.

Mechanical Strength and Structural Performance

Galvanized iron exhibits enhanced mechanical strength due to the protective zinc coating that prevents corrosion, preserving its structural integrity over time. Mild iron, while known for its ductility and ease of welding, often suffers from reduced strength and durability when exposed to environmental stressors. The superior corrosion resistance of galvanized iron translates into improved structural performance, making it more suitable for long-term construction and industrial applications.

Common Applications and Uses

Galvanized iron is primarily used in outdoor and industrial applications such as roofing, fencing, and water pipes due to its corrosion-resistant zinc coating, making it ideal for exposure to moisture and harsh environments. Mild iron, known for its malleability and strength, is commonly employed in construction frameworks, automotive parts, and manufacturing machinery where structural integrity and weldability are essential. Both materials serve distinct purposes based on their properties: galvanized iron for durability against rust and mild iron for versatile fabrication and mechanical strength.

Cost Analysis: Galvanized vs Mild Iron

Galvanized iron typically incurs higher upfront costs compared to mild iron due to the zinc coating process, which adds corrosion resistance and extends the material's lifespan. Mild iron is more economical initially but may require frequent maintenance and replacement, increasing long-term expenses. Cost analysis favors galvanized iron in projects demanding durability and reduced upkeep, despite its higher initial investment.

Maintenance and Longevity

Galvanized iron features a protective zinc coating that prevents rust and corrosion, significantly reducing maintenance efforts compared to mild iron. Mild iron requires regular painting and anti-rust treatments to extend its lifespan, as it is prone to oxidation. The longevity of galvanized iron typically exceeds 30 years outdoors, while untreated mild iron may deteriorate within 5 to 10 years under similar conditions.

Environmental Impact and Sustainability

Galvanized iron involves a zinc coating that protects against rust but raises environmental concerns due to zinc mining and coating processes releasing pollutants and heavy metals, impacting soil and water quality. Mild iron, being uncoated and more recyclable, tends to have a lower environmental footprint, reducing hazardous waste and facilitating sustainable reuse in construction and manufacturing. Choosing mild iron promotes circular economy practices, whereas galvanized iron requires careful waste management to mitigate long-term ecological damage.

Choosing the Right Iron for Your Project

Galvanized iron offers superior corrosion resistance due to its zinc coating, making it ideal for outdoor and moisture-prone projects, while mild iron is softer and easier to weld, suitable for indoor frameworks and decorative work. Consider the environmental exposure and mechanical requirements of your project to determine whether durability or flexibility is the priority. Selecting the right iron type ensures enhanced longevity and performance tailored to specific construction or manufacturing needs.

Galvanized Iron vs Mild Iron Infographic

materialdif.com

materialdif.com