Annealed iron undergoes a heat treatment process that softens the metal, enhancing its ductility and reducing internal stresses, which makes it easier to work with in manufacturing and forming applications. Non-annealed iron retains its original hardness and strength but is more brittle and prone to cracking under stress or impact. Choosing between annealed and non-annealed iron depends on the specific requirements for flexibility, strength, and durability in the intended use.

Table of Comparison

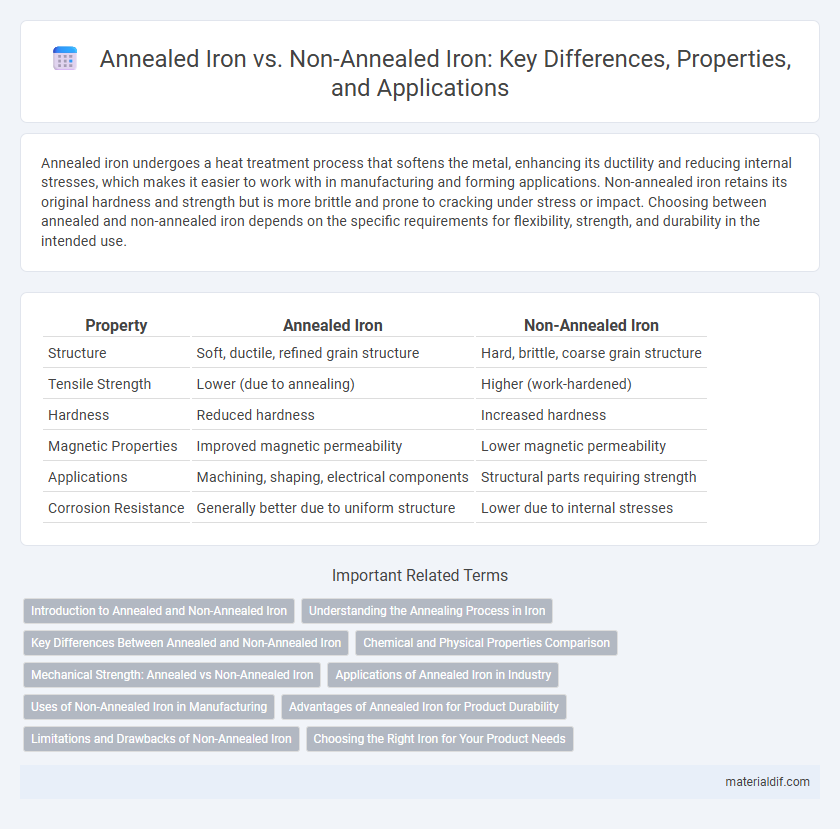

| Property | Annealed Iron | Non-Annealed Iron |

|---|---|---|

| Structure | Soft, ductile, refined grain structure | Hard, brittle, coarse grain structure |

| Tensile Strength | Lower (due to annealing) | Higher (work-hardened) |

| Hardness | Reduced hardness | Increased hardness |

| Magnetic Properties | Improved magnetic permeability | Lower magnetic permeability |

| Applications | Machining, shaping, electrical components | Structural parts requiring strength |

| Corrosion Resistance | Generally better due to uniform structure | Lower due to internal stresses |

Introduction to Annealed and Non-Annealed Iron

Annealed iron undergoes a heat treatment process that softens the metal, improving its ductility and reducing internal stresses, which makes it more malleable for shaping and forming. Non-annealed iron, also known as cold-worked or as-rolled iron, retains a harder, more brittle structure due to the absence of this heat treatment, resulting in higher tensile strength but lower flexibility. The annealing process significantly affects iron's mechanical properties, impacting its behavior in manufacturing and engineering applications.

Understanding the Annealing Process in Iron

Annealed iron undergoes a heat treatment process where the metal is heated to a specific temperature and then slowly cooled, relieving internal stresses and enhancing ductility. Non-annealed iron retains higher hardness and strength but is more prone to brittleness and cracking due to residual stresses from manufacturing. Understanding annealing is crucial for selecting iron materials with desired mechanical properties for applications requiring flexibility and improved machinability.

Key Differences Between Annealed and Non-Annealed Iron

Annealed iron undergoes a heat treatment process that softens the metal, enhancing its ductility and reducing internal stresses, making it easier to shape and work with. Non-annealed iron retains its original hardness and strength but is more brittle and prone to cracking during fabrication. The key differences lie in mechanical properties, with annealed iron offering improved malleability while non-annealed iron provides greater strength and wear resistance.

Chemical and Physical Properties Comparison

Annealed iron undergoes a heat treatment process that alters its microstructure, resulting in reduced hardness and increased ductility compared to non-annealed iron, which remains harder and more brittle due to retained internal stresses. Chemically, both annealed and non-annealed iron maintain the same composition primarily consisting of elemental iron (Fe) with minor carbon content, but annealing can improve resistance to oxidation by relieving lattice strains. Physically, annealed iron exhibits enhanced malleability and improved electrical conductivity, whereas non-annealed iron retains higher tensile strength and is less conductive due to dislocation density.

Mechanical Strength: Annealed vs Non-Annealed Iron

Annealed iron exhibits lower mechanical strength compared to non-annealed iron due to the relief of internal stresses and increased ductility achieved through the annealing process. Non-annealed iron retains higher hardness and tensile strength because it maintains its original microstructure with dislocations and internal stresses intact. This difference makes non-annealed iron more suitable for applications requiring greater mechanical strength and wear resistance.

Applications of Annealed Iron in Industry

Annealed iron, characterized by its improved ductility and reduced hardness due to controlled heat treatment, finds extensive applications in industries requiring malleable and formable materials. It is widely used in manufacturing automotive components, electrical appliances, and structural parts where shaping and welding are critical. The annealing process enhances iron's mechanical properties, making it ideal for fabrication in construction, machinery, and metalworking industries.

Uses of Non-Annealed Iron in Manufacturing

Non-annealed iron, characterized by its higher hardness and tensile strength, is widely used in manufacturing applications requiring durable and wear-resistant components such as cutting tools, springs, and structural parts. Its unsoftened structure provides enhanced mechanical properties ideal for high-stress environments and precision machinery. This form of iron is preferred in industries like automotive and construction where rigidity and strength are critical.

Advantages of Annealed Iron for Product Durability

Annealed iron undergoes a heat treatment process that reduces internal stresses and enhances its ductility, making it less prone to cracking or breaking under stress. This improved flexibility allows annealed iron to better absorb impacts and resist fatigue, significantly extending the lifespan of products. The uniform grain structure achieved through annealing also minimizes brittle failure, contributing to greater overall durability in industrial and construction applications.

Limitations and Drawbacks of Non-Annealed Iron

Non-annealed iron exhibits increased brittleness and higher internal stresses, making it more prone to cracking under mechanical strain. Its limited ductility reduces formability, restricting its use in applications requiring extensive shaping or bending. Furthermore, the lack of annealing treatment results in reduced magnetic softness, impairing performance in electromagnetic devices.

Choosing the Right Iron for Your Product Needs

Annealed iron undergoes controlled heating and slow cooling to enhance ductility, reduce hardness, and improve workability, making it ideal for applications requiring bending and shaping. Non-annealed iron retains higher hardness and strength but is more brittle, suitable for structural uses where rigidity is essential. Selecting the right iron depends on balancing flexibility and strength based on product design requirements and manufacturing processes.

Annealed Iron vs Non-Annealed Iron Infographic

materialdif.com

materialdif.com