Gray iron exhibits superior machinability and excellent vibration damping due to its flake graphite microstructure, making it ideal for engine blocks and machinery bases. White iron contains a hard, carbide-rich structure that provides exceptional wear resistance and strength, commonly used in abrasive environments like grinding mills and pump parts. The distinct microstructures of gray and white iron result in markedly different mechanical properties tailored to specific industrial applications.

Table of Comparison

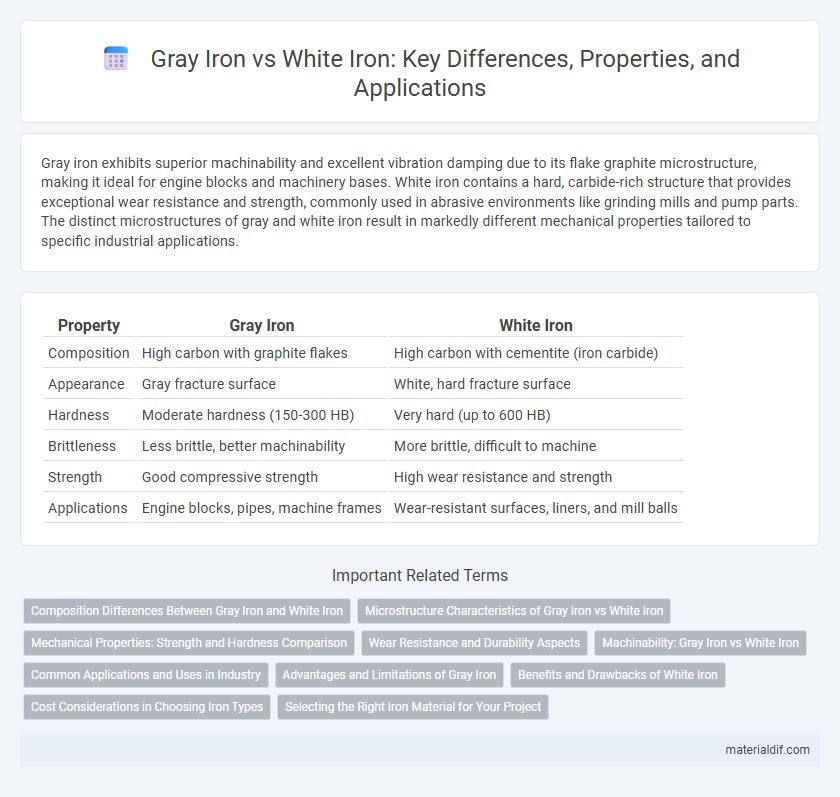

| Property | Gray Iron | White Iron |

|---|---|---|

| Composition | High carbon with graphite flakes | High carbon with cementite (iron carbide) |

| Appearance | Gray fracture surface | White, hard fracture surface |

| Hardness | Moderate hardness (150-300 HB) | Very hard (up to 600 HB) |

| Brittleness | Less brittle, better machinability | More brittle, difficult to machine |

| Strength | Good compressive strength | High wear resistance and strength |

| Applications | Engine blocks, pipes, machine frames | Wear-resistant surfaces, liners, and mill balls |

Composition Differences Between Gray Iron and White Iron

Gray iron contains 2.5-4% carbon primarily in the form of graphite flakes, which enhances its machinability and vibration damping properties. White iron has a similar carbon content range but features carbon combined as iron carbide (cementite), resulting in a hard and brittle microstructure. The difference in carbon morphology directly influences the mechanical behavior and applications of these cast irons.

Microstructure Characteristics of Gray Iron vs White Iron

Gray iron features a microstructure characterized by flake graphite within a pearlitic or ferritic matrix, which enhances its machinability and vibration damping properties. White iron contains cementite (Fe3C) forming a hard, brittle matrix with a lack of free graphite, resulting in high hardness and abrasion resistance. The distinct microstructural differences between gray and white iron directly influence their mechanical properties and industrial applications.

Mechanical Properties: Strength and Hardness Comparison

Gray iron exhibits lower tensile strength, typically around 20,000 to 60,000 psi, due to its graphite flake microstructure, which enhances damping but reduces hardness. White iron demonstrates higher hardness, often exceeding 500 Brinell Hardness Number (BHN), attributed to its cementite-rich microstructure, providing superior wear resistance but brittleness. The toughness of gray iron outperforms white iron, making it preferable for applications requiring vibration damping and machinability rather than extreme hardness.

Wear Resistance and Durability Aspects

Gray iron exhibits excellent wear resistance due to its graphite flakes that provide self-lubricating properties and shock absorption, making it highly durable in applications with abrasive conditions. White iron, characterized by its hard, crystalline carbides, offers superior wear resistance against impact and abrasion but tends to be more brittle, reducing its overall durability under dynamic stresses. The choice between gray and white iron depends on balancing wear resistance needs with the required toughness and durability for specific industrial uses.

Machinability: Gray Iron vs White Iron

Gray iron offers superior machinability compared to white iron due to its graphite microstructure, which acts as a natural lubricant and reduces tool wear. White iron's hard and brittle cementite phases increase tool wear and make machining difficult and less efficient. The machinability index for gray iron is typically two to three times higher than that of white iron.

Common Applications and Uses in Industry

Gray iron is widely used in automotive engine blocks, pipes, and machinery bases due to its excellent vibration damping and machinability. White iron, with its hardness and abrasion resistance, is preferred for wear-resistant surfaces like crusher liners, shot-blasting equipment, and grinding mills. Industries leverage gray iron for structural components and white iron for high-impact, wear-intensive applications.

Advantages and Limitations of Gray Iron

Gray iron offers excellent machinability and vibration damping due to its graphite flake structure, making it ideal for automotive engine blocks and machinery bases. It has good thermal conductivity and wear resistance but lower tensile strength and brittleness compared to white iron, limiting its use in high-stress or impact applications. The porous graphite in gray iron also enhances lubrication, reducing friction in moving parts.

Benefits and Drawbacks of White Iron

White iron offers exceptional hardness and wear resistance due to its high carbon content that forms cementite, making it ideal for applications involving abrasive materials. However, its brittleness results in poor impact resistance and low ductility, limiting its use in situations requiring toughness. Despite superior wear properties, white iron is challenging to machine and prone to cracking under mechanical stress.

Cost Considerations in Choosing Iron Types

Gray iron generally offers lower production costs due to its simpler casting process and higher machinability, making it a cost-effective choice for large-scale manufacturing. White iron, characterized by its harder and more wear-resistant surface, typically incurs higher expenses in casting and machining, increasing overall production costs. Selecting between gray and white iron hinges on balancing upfront material and processing costs with the desired durability and wear resistance for specific industrial applications.

Selecting the Right Iron Material for Your Project

Gray iron offers excellent machinability and vibration damping, making it ideal for automotive engine blocks and machinery bases. White iron, characterized by its hardness and abrasion resistance, is preferred for wear-resistant applications such as crushers and grinding mills. Selecting the right iron material depends on balancing durability needs with cost efficiency and machinability for your project's specific requirements.

Gray Iron vs White Iron Infographic

materialdif.com

materialdif.com