Powder metallurgy offers superior control over the microstructure and composition of iron components, resulting in enhanced mechanical properties and reduced material waste compared to traditional iron casting. Iron casting, however, allows for the production of larger and more complex geometries, making it suitable for heavy-duty applications and mass production. Selecting between powder metallurgy and iron casting depends on the specific requirements for precision, strength, and manufacturing volume.

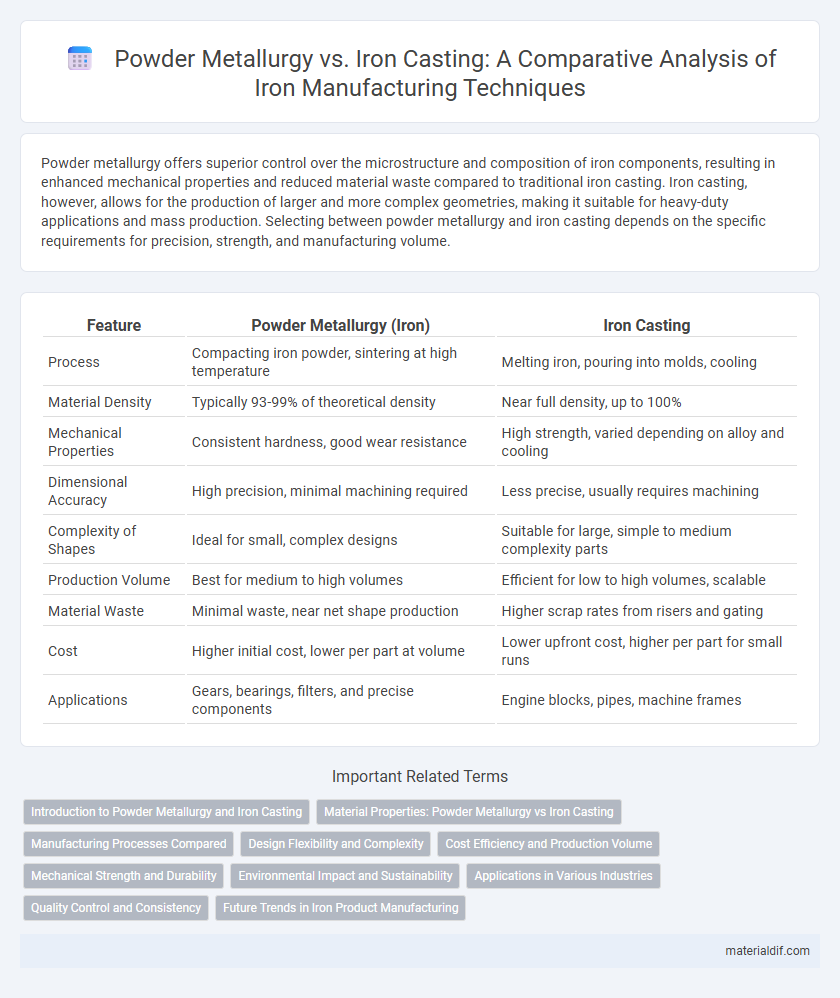

Table of Comparison

| Feature | Powder Metallurgy (Iron) | Iron Casting |

|---|---|---|

| Process | Compacting iron powder, sintering at high temperature | Melting iron, pouring into molds, cooling |

| Material Density | Typically 93-99% of theoretical density | Near full density, up to 100% |

| Mechanical Properties | Consistent hardness, good wear resistance | High strength, varied depending on alloy and cooling |

| Dimensional Accuracy | High precision, minimal machining required | Less precise, usually requires machining |

| Complexity of Shapes | Ideal for small, complex designs | Suitable for large, simple to medium complexity parts |

| Production Volume | Best for medium to high volumes | Efficient for low to high volumes, scalable |

| Material Waste | Minimal waste, near net shape production | Higher scrap rates from risers and gating |

| Cost | Higher initial cost, lower per part at volume | Lower upfront cost, higher per part for small runs |

| Applications | Gears, bearings, filters, and precise components | Engine blocks, pipes, machine frames |

Introduction to Powder Metallurgy and Iron Casting

Powder metallurgy involves compacting fine iron powders into desired shapes and sintering them at high temperatures to achieve solid parts with controlled microstructures and minimal waste. Iron casting entails melting iron and pouring it into molds to create complex shapes, offering high mechanical strength but often requiring additional machining. Both processes serve different manufacturing needs, with powder metallurgy excelling in precision and material utilization, while iron casting is preferred for larger, intricate components.

Material Properties: Powder Metallurgy vs Iron Casting

Powder metallurgy produces iron components with superior uniformity and fine microstructure, resulting in enhanced mechanical properties such as higher tensile strength and wear resistance compared to traditional iron casting. Iron casting often contains larger grains and porosity, which can lead to decreased toughness and fatigue resistance. The controlled particle size distribution in powder metallurgy enables tailored material properties that are difficult to achieve through conventional casting methods.

Manufacturing Processes Compared

Powder metallurgy involves pressing and sintering iron powders to produce components with precise dimensions and minimal waste, offering superior material utilization and uniform microstructure compared to iron casting. Iron casting melts iron to pour into molds, enabling complex shapes but often resulting in porosity and requiring additional machining for dimensional accuracy. Manufacturing efficiency in powder metallurgy typically exceeds that of casting due to reduced finishing needs and enhanced mechanical properties tailored through controlled powder compositions.

Design Flexibility and Complexity

Powder metallurgy offers superior design flexibility and allows for the production of intricate iron components with precise tolerances and complex geometries that are difficult to achieve through traditional iron casting methods. The process enables the creation of porous or graded structures, optimizing material properties for specific applications without the need for extensive machining or tooling changes. In contrast, iron casting is limited by mold design constraints and typically results in heavier components with less detailed features and reduced geometric complexity.

Cost Efficiency and Production Volume

Powder metallurgy offers higher material utilization and lower waste generation than iron casting, making it more cost-efficient for small to medium production volumes with complex geometries. Iron casting is more economical for high production volumes due to lower per-unit costs despite higher material waste and longer cycle times. Choosing between powder metallurgy and iron casting depends on balancing initial tooling costs, production volume, and required mechanical properties.

Mechanical Strength and Durability

Powder metallurgy produces iron components with superior mechanical strength due to fine, uniform microstructures and minimal porosity, enhancing wear resistance and fatigue life. Iron casting, while cost-effective for complex shapes, often exhibits lower tensile strength and durability because of inherent defects such as shrinkage cavities and coarse grain structures. Advanced heat treatments further improve powder metallurgy parts, making them ideal for high-performance and load-bearing applications.

Environmental Impact and Sustainability

Powder metallurgy of iron generates significantly less waste and reduces energy consumption by using near-net shape manufacturing, leading to lower greenhouse gas emissions compared to traditional iron casting. Iron casting involves melting large quantities of metal, resulting in higher carbon dioxide output and increased use of non-renewable energy sources. Sustainable iron powder production enables material recycling and minimal scrap, aligning with green manufacturing principles and reducing overall environmental impact.

Applications in Various Industries

Powder metallurgy offers superior precision and material efficiency in producing complex iron components for aerospace, automotive, and medical industries, enabling lightweight and high-performance parts. Iron casting excels in manufacturing large, heavy-duty components for construction, machinery, and infrastructure due to its strength and durability. Both methods serve critical industrial applications, with powder metallurgy favored for intricate designs and iron casting preferred for robust structural parts.

Quality Control and Consistency

Powder metallurgy offers superior quality control and consistency in iron production due to precise particle size distribution and controlled sintering processes, resulting in uniform microstructures and mechanical properties. In contrast, iron casting often faces variability from molten metal cooling rates and mold conditions, leading to inconsistencies like porosity and segregation. These differences make powder metallurgy ideal for high-performance parts requiring tight tolerances and reliable mechanical integrity.

Future Trends in Iron Product Manufacturing

Advancements in powder metallurgy are driving future trends in iron product manufacturing by enabling precise control over microstructure and composition, leading to enhanced mechanical properties and reduced material waste compared to traditional iron casting methods. Emerging additive manufacturing techniques integrated with powder metallurgy offer increased design flexibility and production efficiency for complex iron components in automotive and aerospace industries. Iron casting remains relevant for large-scale, cost-effective production, but its evolution increasingly incorporates automation and advanced simulation tools to improve quality and reduce defects.

Powder Metallurgy vs Iron Casting Infographic

materialdif.com

materialdif.com