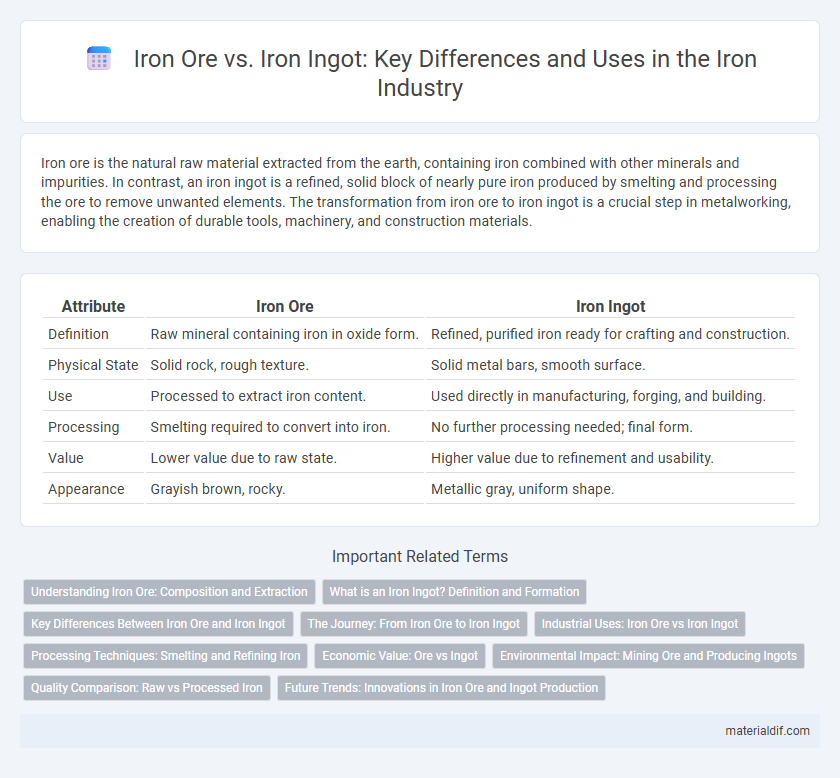

Iron ore is the natural raw material extracted from the earth, containing iron combined with other minerals and impurities. In contrast, an iron ingot is a refined, solid block of nearly pure iron produced by smelting and processing the ore to remove unwanted elements. The transformation from iron ore to iron ingot is a crucial step in metalworking, enabling the creation of durable tools, machinery, and construction materials.

Table of Comparison

| Attribute | Iron Ore | Iron Ingot |

|---|---|---|

| Definition | Raw mineral containing iron in oxide form. | Refined, purified iron ready for crafting and construction. |

| Physical State | Solid rock, rough texture. | Solid metal bars, smooth surface. |

| Use | Processed to extract iron content. | Used directly in manufacturing, forging, and building. |

| Processing | Smelting required to convert into iron. | No further processing needed; final form. |

| Value | Lower value due to raw state. | Higher value due to refinement and usability. |

| Appearance | Grayish brown, rocky. | Metallic gray, uniform shape. |

Understanding Iron Ore: Composition and Extraction

Iron ore primarily consists of iron oxides such as hematite (Fe2O3) and magnetite (Fe3O4), which are mined from the Earth's crust. The extraction process involves crushing, grinding, and magnetic separation to concentrate the ore, followed by smelting in blast furnaces where carbon reduces the oxides to produce molten iron. This molten iron is then cast into iron ingots, which serve as a raw material for steelmaking and other metallurgical processes.

What is an Iron Ingot? Definition and Formation

An iron ingot is a solid block of refined iron produced by smelting iron ore at high temperatures to remove impurities. This process involves melting the ore in a furnace, allowing molten iron to be poured into molds where it solidifies into ingots. Iron ingots serve as a primary raw material for manufacturing steel and various iron-based products in industrial applications.

Key Differences Between Iron Ore and Iron Ingot

Iron ore is the raw mineral extracted from the earth containing iron combined with oxygen and other elements, requiring smelting to extract pure iron. An iron ingot is a refined, solid block of nearly pure iron produced after melting and pouring the purified metal into molds. The key differences between iron ore and iron ingots lie in their composition, processing requirements, and usability; ore is unprocessed and impure, whereas ingots are processed, standardized, and ready for manufacturing applications.

The Journey: From Iron Ore to Iron Ingot

Iron ore undergoes a refining process that involves crushing, smelting, and purification to extract usable metal. High-temperature furnaces reduce the ore to molten iron, separating impurities and producing a solidified iron ingot. This transformation enhances the metal's malleability and prepares it for diverse industrial applications.

Industrial Uses: Iron Ore vs Iron Ingot

Iron ore serves as the primary raw material extracted from the earth containing valuable iron minerals, which undergo smelting to produce iron ingots. Iron ingots, also known as iron bars, provide a refined, malleable form utilized extensively in manufacturing fundamental industrial components, machinery parts, and construction materials. Industrial applications rely on iron ingots for their consistent purity and mechanical properties, whereas iron ore is essential in the initial stages of metallurgy and steel production.

Processing Techniques: Smelting and Refining Iron

Iron ore undergoes smelting, a high-temperature process where it is heated with a reducing agent like coke in a blast furnace to extract molten iron. This molten iron is then refined to remove impurities such as carbon, sulfur, and phosphorus, improving its quality and creating usable iron ingots. Refining techniques like basic oxygen steelmaking or electric arc furnaces further enhance the purity and mechanical properties of the ingots for industrial applications.

Economic Value: Ore vs Ingot

Iron ore holds significant economic value as the essential raw material extracted from the earth, fueling the mining sector and global trade with millions of tons transported annually. Iron ingots, produced through smelting and refining iron ore, command higher market prices due to their enhanced purity and utility in manufacturing steel and other iron-based products. The value difference between raw iron ore and processed iron ingots reflects the added industrial processing costs, increased material quality, and greater demand in construction and automotive industries worldwide.

Environmental Impact: Mining Ore and Producing Ingots

Mining iron ore generates significant environmental impacts including habitat disruption, soil erosion, and water contamination from tailings. Producing iron ingots from ore demands high energy consumption and emits large quantities of CO2, contributing to climate change. Implementing advanced technologies and recycling scrap metal can reduce the overall ecological footprint of iron production.

Quality Comparison: Raw vs Processed Iron

Iron ore contains impurities such as silica, sulfur, and phosphorus that reduce its quality and limit its direct use in manufacturing. Iron ingots, produced through smelting and refining, have higher purity levels and improved structural integrity, making them essential for construction, automotive, and industrial applications. The transformation from raw iron ore to processed iron ingots enhances mechanical properties, corrosion resistance, and overall material durability.

Future Trends: Innovations in Iron Ore and Ingot Production

Innovations in iron ore processing emphasize enhanced efficiency through advanced beneficiation technologies and sustainable extraction methods, reducing environmental impact while maximizing yield. Iron ingot production is increasingly adopting electric arc furnace (EAF) technology and additive manufacturing to improve metal quality and customization, catering to emerging industrial needs. Future trends highlight integration of digital monitoring and AI-driven optimization to streamline production workflows and ensure consistent material performance in steel manufacturing.

Iron Ore vs Iron Ingot Infographic

materialdif.com

materialdif.com