Forged iron features enhanced strength and durability due to its dense, grain-aligned structure formed under high pressure, making it ideal for heavy-duty applications. Sintered iron is produced by compressing and heating iron powder without melting, resulting in a porous yet lightweight material best suited for components requiring precise shapes and moderate strength. Choosing between forged and sintered iron depends on the balance needed between mechanical strength and manufacturing complexity.

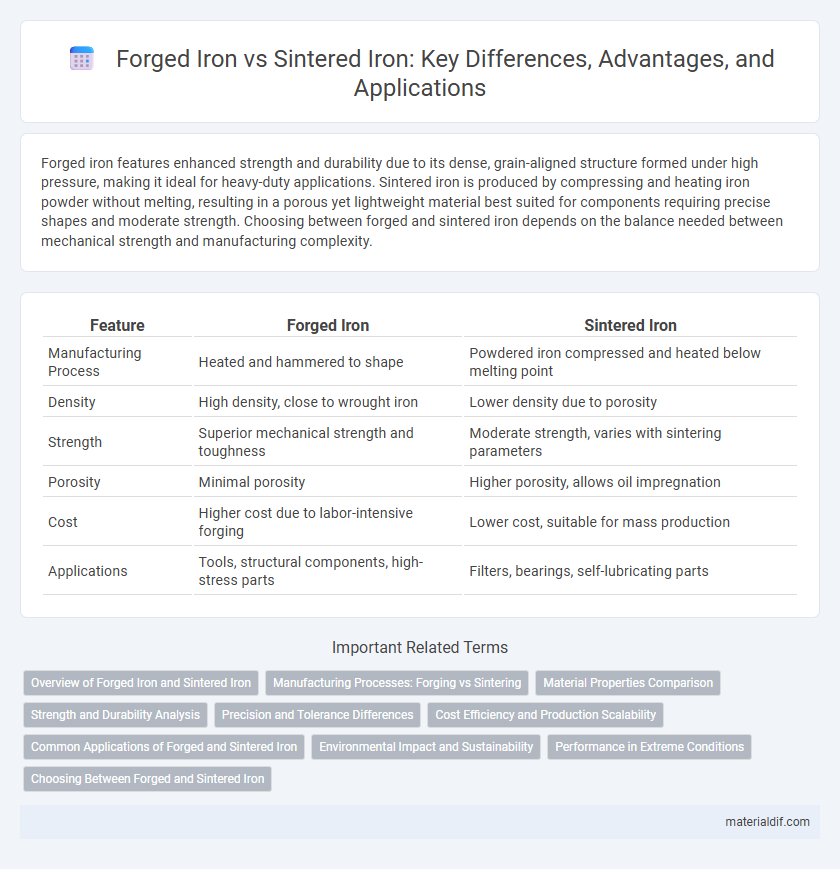

Table of Comparison

| Feature | Forged Iron | Sintered Iron |

|---|---|---|

| Manufacturing Process | Heated and hammered to shape | Powdered iron compressed and heated below melting point |

| Density | High density, close to wrought iron | Lower density due to porosity |

| Strength | Superior mechanical strength and toughness | Moderate strength, varies with sintering parameters |

| Porosity | Minimal porosity | Higher porosity, allows oil impregnation |

| Cost | Higher cost due to labor-intensive forging | Lower cost, suitable for mass production |

| Applications | Tools, structural components, high-stress parts | Filters, bearings, self-lubricating parts |

Overview of Forged Iron and Sintered Iron

Forged iron is produced by heating and hammering iron to shape, resulting in a dense, strong material with superior tensile strength and durability. Sintered iron is created by compacting iron powder and heating it below melting point, which allows for intricate shapes and efficient material use but typically has lower mechanical strength than forged iron. Each process affects the microstructure and properties, making forged iron ideal for heavy-duty applications while sintered iron suits precision components with complex geometries.

Manufacturing Processes: Forging vs Sintering

Forged iron undergoes a manufacturing process involving the heating and hammering of iron to shape it through plastic deformation, enhancing its strength and grain structure. Sintered iron is produced by compacting iron powder and heating it below its melting point to bond particles without fully liquefying, resulting in a porous but uniform microstructure. Forging yields dense, tough materials ideal for high-stress applications, while sintering allows complex shapes with controlled porosity for applications requiring wear resistance or lubrication retention.

Material Properties Comparison

Forged iron exhibits superior tensile strength and toughness compared to sintered iron due to its denser microstructure and grain alignment achieved through hammering or pressing at high temperatures. Sintered iron, produced by compacting and heating iron powder, often presents higher porosity, resulting in reduced mechanical strength and increased brittleness. Corrosion resistance in forged iron is generally enhanced because of its lower permeability and fewer internal voids, making it preferable for high-stress, durable applications.

Strength and Durability Analysis

Forged iron exhibits superior strength and durability due to its dense microstructure formed under high pressure, which enhances grain alignment and reduces internal defects. Sintered iron, produced through powder metallurgy, offers uniform material properties but tends to have lower tensile strength and fatigue resistance compared to forged iron. The enhanced mechanical properties of forged iron make it more suitable for high-stress applications requiring long-term durability.

Precision and Tolerance Differences

Forged iron exhibits superior grain structure and density, resulting in higher precision and tighter tolerances compared to sintered iron, which often has porosity variations affecting dimensional accuracy. Forging aligns the metal's internal fibers, enhancing strength and consistency for applications requiring exact measurements. In contrast, sintered iron's layer-by-layer production can lead to slight dimensional deviations, making it less ideal for components with critical tolerance requirements.

Cost Efficiency and Production Scalability

Forged iron offers superior mechanical strength and durability, making it ideal for applications requiring high load-bearing capacity, but its production involves higher costs due to labor-intensive processes and longer cycle times. Sintered iron provides cost efficiency through powder metallurgy, enabling mass production with lower material waste and shorter manufacturing cycles, which significantly enhances production scalability. Choosing between forged and sintered iron depends on balancing the need for performance against budget constraints and volume requirements in industrial manufacturing.

Common Applications of Forged and Sintered Iron

Forged iron is commonly utilized in automotive parts, construction tools, and heavy machinery components due to its superior strength and durability. Sintered iron finds widespread use in manufacturing complex-shaped components like gears, filters, and bushings, benefiting from its precision and material efficiency. Both materials serve critical roles in industries requiring specific mechanical properties and cost-effective production methods.

Environmental Impact and Sustainability

Forged iron production typically consumes more energy due to high-temperature processes, resulting in a larger carbon footprint compared to sintered iron, which uses lower temperatures and compacts powder without melting. Sintered iron supports sustainability by enabling the use of recycled metal powders, reducing raw material extraction and waste generation. Both methods contribute to the durability and longevity of iron products, but sintered iron offers a more environmentally friendly alternative through efficient material usage and lower emissions.

Performance in Extreme Conditions

Forged iron exhibits superior mechanical strength and impact resistance compared to sintered iron, making it more reliable in extreme temperature and high-stress environments. The dense grain structure achieved through forging enhances durability and reduces the risk of fractures under thermal cycling and heavy loads. Sintered iron, while cost-effective and good for uniform porosity, generally lacks the toughness needed for critical applications exposed to harsh conditions.

Choosing Between Forged and Sintered Iron

Forged iron offers superior strength and durability due to its dense grain structure formed under high pressure, making it ideal for heavy-duty applications requiring impact resistance. Sintered iron, produced through powdered metallurgy, allows for complex shapes and precise tolerances with better material utilization but typically has lower mechanical strength compared to forged counterparts. Choosing between forged and sintered iron depends on balancing performance requirements, production complexity, and cost efficiency in your specific engineering project.

Forged Iron vs Sintered Iron Infographic

materialdif.com

materialdif.com