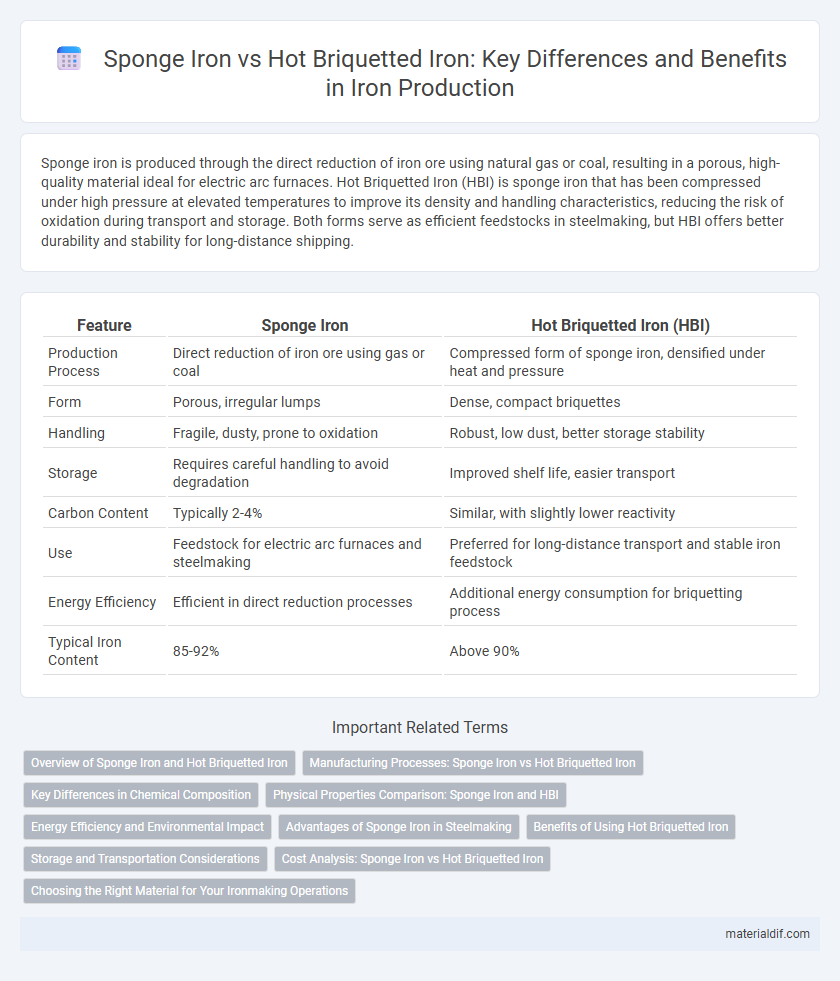

Sponge iron is produced through the direct reduction of iron ore using natural gas or coal, resulting in a porous, high-quality material ideal for electric arc furnaces. Hot Briquetted Iron (HBI) is sponge iron that has been compressed under high pressure at elevated temperatures to improve its density and handling characteristics, reducing the risk of oxidation during transport and storage. Both forms serve as efficient feedstocks in steelmaking, but HBI offers better durability and stability for long-distance shipping.

Table of Comparison

| Feature | Sponge Iron | Hot Briquetted Iron (HBI) |

|---|---|---|

| Production Process | Direct reduction of iron ore using gas or coal | Compressed form of sponge iron, densified under heat and pressure |

| Form | Porous, irregular lumps | Dense, compact briquettes |

| Handling | Fragile, dusty, prone to oxidation | Robust, low dust, better storage stability |

| Storage | Requires careful handling to avoid degradation | Improved shelf life, easier transport |

| Carbon Content | Typically 2-4% | Similar, with slightly lower reactivity |

| Use | Feedstock for electric arc furnaces and steelmaking | Preferred for long-distance transport and stable iron feedstock |

| Energy Efficiency | Efficient in direct reduction processes | Additional energy consumption for briquetting process |

| Typical Iron Content | 85-92% | Above 90% |

Overview of Sponge Iron and Hot Briquetted Iron

Sponge iron, also known as direct reduced iron (DRI), is produced by reducing iron ore in its solid state using a reducing gas or carbon-based material, resulting in a porous, high-purity iron product ideal for electric arc furnace steelmaking. Hot Briquetted Iron (HBI) is compacted sponge iron formed under high pressure and temperature into dense briquettes, enhancing its transportation safety and storage stability while maintaining metallurgical quality. Both materials serve as efficient iron sources in steel production, with HBI offering improved handling characteristics compared to loose sponge iron.

Manufacturing Processes: Sponge Iron vs Hot Briquetted Iron

Sponge Iron is produced through direct reduction of iron ore using reducing gases or coal-based processes, resulting in porous, metallic iron. Hot Briquetted Iron (HBI) is derived by compressing sponge iron at high temperatures into dense, compact briquettes, enhancing its transportation and storage properties. The manufacturing difference lies in the direct reduction method for sponge iron and the subsequent hot briquetting step that transforms it into HBI for improved handling.

Key Differences in Chemical Composition

Sponge iron primarily consists of direct reduced iron with minimal carbon content, typically below 0.2%, which preserves its sponge-like porous structure. Hot Briquetted Iron (HBI) undergoes compaction at elevated temperatures, resulting in a denser product with slightly higher carbon content, often around 1-2%, due to partial carburization during the briquetting process. These variations in chemical composition significantly influence their metallurgical properties and suitability for different steelmaking applications.

Physical Properties Comparison: Sponge Iron and HBI

Sponge iron exhibits a porous, sponge-like structure with a higher surface area and lower density, making it more reactive and suitable for direct reduction processes. Hot Briquetted Iron (HBI) is a compacted, denser form of sponge iron with improved physical strength, reduced dust, and enhanced handling characteristics, facilitating safer transport and storage. The denser nature of HBI leads to lower oxidation rates during shipment, providing superior durability compared to loose sponge iron.

Energy Efficiency and Environmental Impact

Sponge iron production typically consumes more energy and releases higher carbon emissions compared to Hot Briquetted Iron (HBI), which undergoes a compacting process that improves transportation efficiency and reduces dust emissions. HBI's densification results in lower energy losses during handling and steelmaking, making it a more environmentally sustainable choice. Adopting HBI can significantly reduce the carbon footprint in ironmaking by enhancing energy savings and minimizing pollution.

Advantages of Sponge Iron in Steelmaking

Sponge iron offers significant advantages in steelmaking due to its high purity and low sulfur content, which improves the quality of the final steel product. Its porous structure allows for efficient melting and reduced energy consumption compared to Hot Briquetted Iron (HBI). Additionally, sponge iron's lower cost and easier handling contribute to more flexible and economical steel production processes.

Benefits of Using Hot Briquetted Iron

Hot Briquetted Iron (HBI) offers superior benefits in ironmaking compared to Sponge Iron due to its higher density and lower reactivity, enhancing transportation safety and reducing oxidation losses. The compact form of HBI minimizes storage space requirements and improves handling efficiency in steel production facilities. Using HBI leads to more consistent metallurgical properties and reduces impurities, contributing to higher-quality steel output.

Storage and Transportation Considerations

Sponge Iron features a porous and brittle structure requiring careful handling to prevent oxidation and degradation during storage, often necessitating sealed or covered environments with minimal moisture exposure. Hot Briquetted Iron (HBI), being densely compacted and conditioned at elevated temperatures, offers enhanced resistance to oxidation and easier transportation, reducing spillage and dust generation. These properties make HBI preferable for long-distance shipping and extended storage periods compared to sponge iron.

Cost Analysis: Sponge Iron vs Hot Briquetted Iron

Sponge iron manufacturing incurs lower raw material costs due to direct reduction of iron ore without the need for briquetting, resulting in more economical production for steelmakers. Hot Briquetted Iron (HBI) commands a premium price owing to its higher density and enhanced transportability, which reduces shipping expenses and material losses during handling. Overall, the decision between sponge iron and HBI hinges on balancing lower initial production costs against the advantages of improved logistics and storage offered by HBI.

Choosing the Right Material for Your Ironmaking Operations

Sponge Iron offers high purity and consistent size, ideal for electric arc furnace operations requiring efficient melting and reduced impurity levels. Hot Briquetted Iron (HBI) provides excellent density and ease of handling, making it suitable for long-distance transportation and blending in blast furnaces. Selecting between Sponge Iron and HBI depends on factors such as operational scale, transportation logistics, and specific metallurgical requirements of the ironmaking process.

Sponge Iron vs Hot Briquetted Iron Infographic

materialdif.com

materialdif.com