Iron ore is the primary raw material extracted from the Earth's crust, containing iron minerals that require smelting to produce pure iron. Scrap iron consists of recycled metal from manufactured iron products, reducing the need for new mining and lowering environmental impact. Using scrap iron supports sustainable manufacturing by conserving natural resources and energy compared to processing iron ore.

Table of Comparison

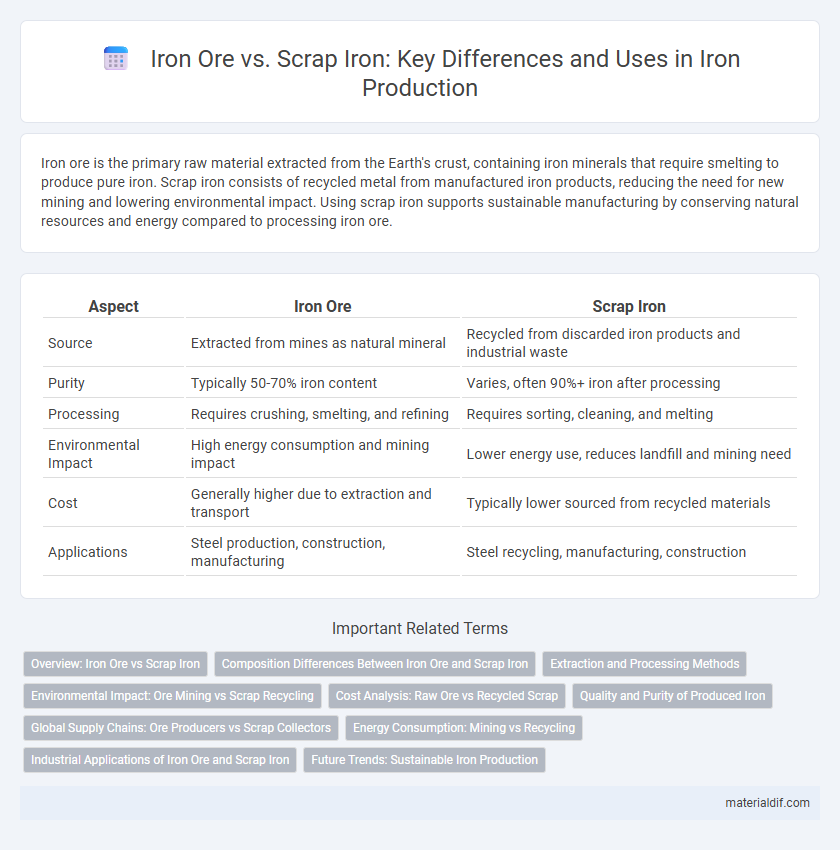

| Aspect | Iron Ore | Scrap Iron |

|---|---|---|

| Source | Extracted from mines as natural mineral | Recycled from discarded iron products and industrial waste |

| Purity | Typically 50-70% iron content | Varies, often 90%+ iron after processing |

| Processing | Requires crushing, smelting, and refining | Requires sorting, cleaning, and melting |

| Environmental Impact | High energy consumption and mining impact | Lower energy use, reduces landfill and mining need |

| Cost | Generally higher due to extraction and transport | Typically lower sourced from recycled materials |

| Applications | Steel production, construction, manufacturing | Steel recycling, manufacturing, construction |

Overview: Iron Ore vs Scrap Iron

Iron ore is the raw mineral extracted from the earth, primarily composed of iron oxides, serving as the fundamental source for iron production in steelmaking. Scrap iron consists of recycled metal materials collected from discarded iron products, offering a sustainable and cost-effective alternative for steel manufacturing. Utilizing scrap iron reduces the demand for mining iron ore, lowering environmental impact and energy consumption in the production process.

Composition Differences Between Iron Ore and Scrap Iron

Iron ore primarily consists of iron oxides such as hematite (Fe2O3) and magnetite (Fe3O4), containing varying amounts of impurities like silica, alumina, and sulfur. Scrap iron is composed of recycled pure iron or iron alloys, often mixed with traces of carbon, manganese, and other metals from its previous use in manufacturing. The key difference lies in ore requiring beneficiation to extract usable iron, whereas scrap iron is already metallic and ready for melting in steel production processes.

Extraction and Processing Methods

Iron ore extraction primarily involves mining techniques such as open-pit and underground mining to retrieve iron-rich minerals like hematite and magnetite from the earth. Processing of iron ore includes crushing, grinding, magnetic separation, and smelting in blast furnaces to produce pig iron. Scrap iron, sourced from recycled metal, undergoes collection, sorting, and shredding before being melted in electric arc furnaces, a process requiring less energy and emitting fewer pollutants compared to ore smelting.

Environmental Impact: Ore Mining vs Scrap Recycling

Iron ore mining significantly impacts the environment due to habitat destruction, soil erosion, and high energy consumption, contributing to greenhouse gas emissions and water pollution. Scrap iron recycling reduces environmental burden by lowering the need for mining, decreasing energy use by up to 75%, and minimizing carbon emissions and waste generation. The recycling process supports sustainable resource management and reduces landfill dependency compared to ore extraction.

Cost Analysis: Raw Ore vs Recycled Scrap

Iron ore extraction incurs higher costs due to mining, transportation, and beneficiation processes, with average expenses ranging from $50 to $120 per ton depending on location and ore grade. Recycled scrap iron offers significant cost savings, typically priced between $200 and $350 per ton but requiring lower energy inputs and reducing environmental impact, making it economically favorable in steel production. The cost gap is influenced by fluctuating market demand, scrap availability, and regulations affecting emissions and resource usage.

Quality and Purity of Produced Iron

Iron ore generally produces higher purity iron due to its natural mineral composition, containing iron oxides that are directly reduced in blast furnaces. Scrap iron quality varies significantly based on its source and contamination levels, often requiring extensive sorting and treatment to achieve comparable purity. Industrial processes favor iron ore for applications demanding consistent high-grade iron, while scrap iron suits cost-sensitive uses with moderate purity requirements.

Global Supply Chains: Ore Producers vs Scrap Collectors

Iron ore dominates global supply chains as the primary raw material for steel production, with major producers like Australia, Brazil, and India exporting millions of tons annually to steel mills worldwide. Scrap iron plays a crucial role in circular economies, sourced by scrap collectors and recyclers to reduce reliance on virgin ore and lower production costs in electric arc furnace steelmaking. The interplay between ore producers and scrap collectors shapes supply chain resilience, pricing dynamics, and sustainability outcomes in the global iron and steel industry.

Energy Consumption: Mining vs Recycling

Recycling scrap iron consumes up to 75% less energy compared to mining and processing iron ore, significantly reducing greenhouse gas emissions. Mining iron ore involves energy-intensive extraction, transportation, and smelting processes, which account for the majority of the sector's carbon footprint. Utilizing recycled scrap iron not only conserves natural resources but also lowers operational costs and environmental impact in steel production.

Industrial Applications of Iron Ore and Scrap Iron

Iron ore serves as the primary raw material in steel manufacturing, supplying essential iron content for producing new steel products used in construction, automotive, and heavy machinery industries. Scrap iron, derived from recycled steel and iron products, plays a crucial role in reducing production costs and environmental impact by being melted and remolded in electric arc furnaces for secondary steelmaking. Industrial applications prioritize iron ore for large-scale steel production due to its high purity and availability, while scrap iron offers a sustainable, energy-efficient alternative for manufacturing structural components and tools.

Future Trends: Sustainable Iron Production

Future trends in sustainable iron production emphasize increasing the use of scrap iron due to its lower environmental impact compared to iron ore mining. Recycling scrap iron reduces carbon emissions, energy consumption, and the depletion of natural resources, aligning with global climate goals. Advances in electric arc furnace technology further enhance the efficiency and sustainability of scrap-based iron manufacturing.

Iron Ore vs Scrap Iron Infographic

materialdif.com

materialdif.com