Iron pipes are hollow cylindrical tubes mainly used for transporting fluids or gases, offering durability and corrosion resistance in plumbing and construction. Iron rods are solid, strong bars primarily utilized for reinforcement in concrete structures and metal fabrication due to their high tensile strength. Understanding the distinct applications and physical properties of iron pipes and rods ensures optimal material selection for construction and industrial projects.

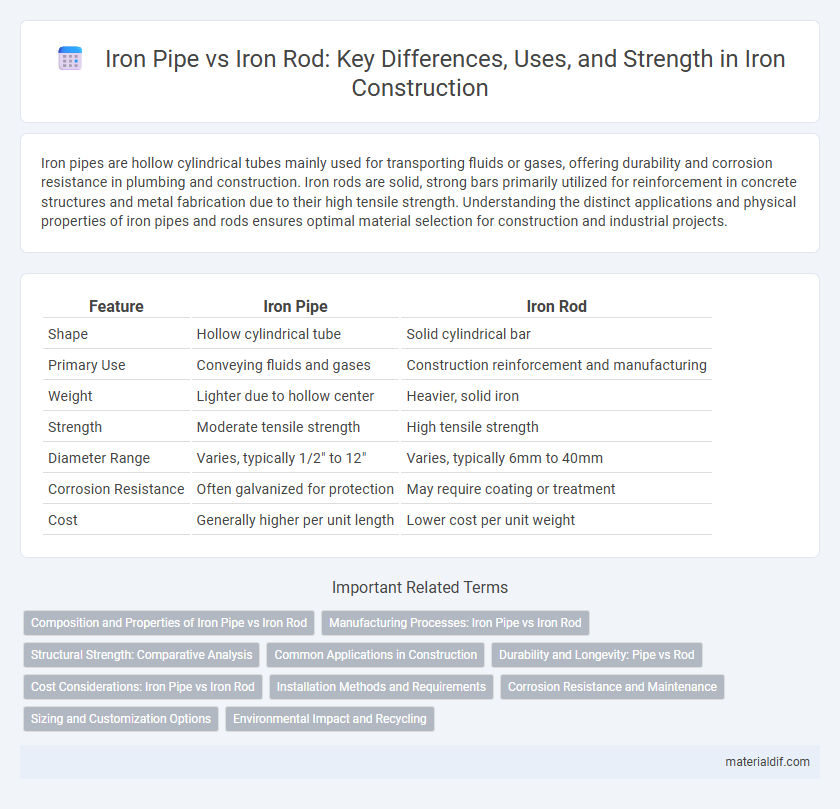

Table of Comparison

| Feature | Iron Pipe | Iron Rod |

|---|---|---|

| Shape | Hollow cylindrical tube | Solid cylindrical bar |

| Primary Use | Conveying fluids and gases | Construction reinforcement and manufacturing |

| Weight | Lighter due to hollow center | Heavier, solid iron |

| Strength | Moderate tensile strength | High tensile strength |

| Diameter Range | Varies, typically 1/2" to 12" | Varies, typically 6mm to 40mm |

| Corrosion Resistance | Often galvanized for protection | May require coating or treatment |

| Cost | Generally higher per unit length | Lower cost per unit weight |

Composition and Properties of Iron Pipe vs Iron Rod

Iron pipes are typically made from cast iron or ductile iron, featuring a hollow cylindrical shape that offers high tensile strength and resistance to corrosion, ideal for fluid transport. Iron rods, composed mainly of mild steel or wrought iron, provide solid, flexible, and durable structural support due to their uniform cross-section and enhanced malleability. The distinct compositions influence their mechanical properties, with pipes excelling in pressure resistance and rods in tensile strength and load-bearing capacity.

Manufacturing Processes: Iron Pipe vs Iron Rod

Iron pipes are typically manufactured through a process called centrifugal casting or welding, where molten iron is shaped into a hollow cylindrical form or welded from rolled iron sheets. Iron rods are generally produced by hot rolling or drawing, where solid billets are heated and deformed to achieve the desired solid cylindrical shape. The manufacturing differences result in iron pipes having a hollow structure suitable for fluid conduction, while iron rods maintain a solid form used in construction and reinforcement.

Structural Strength: Comparative Analysis

Iron pipes exhibit superior compression strength and are designed to withstand internal pressure, making them ideal for fluid transport and structural applications requiring hollow sections. Iron rods possess higher tensile strength and rigidity due to their solid cross-section, providing excellent support in frameworks subjected to bending and tension forces. The choice between iron pipe and iron rod depends on the load type, with pipes excelling in compressive loads and rods in tensile and bending scenarios.

Common Applications in Construction

Iron pipes are primarily used for plumbing, water supply systems, and structural support where fluid conveyance or hollow sections are required. Iron rods serve as reinforcement bars in concrete structures, providing tensile strength in foundations, slabs, and beams. Both materials are essential in construction, with pipes focusing on fluid transport and rods enhancing structural integrity.

Durability and Longevity: Pipe vs Rod

Iron pipes exhibit superior durability in fluid transport due to their hollow structure allowing resistance to internal pressure and corrosion, especially when coated or galvanized. Iron rods, being solid, offer greater tensile strength and longevity in structural applications by withstanding heavy loads and stress without deformation. The choice between iron pipe and iron rod depends on specific durability requirements, with pipes favored for longevity in plumbing and rods preferred for enduring structural integrity.

Cost Considerations: Iron Pipe vs Iron Rod

Iron pipes generally cost less than iron rods due to differences in manufacturing processes and material usage, with pipes being hollow and rods solid. The price of iron rods is typically higher because their solid structure requires more raw material, leading to increased weight and cost per unit length. When budgeting for construction or manufacturing projects, selecting iron pipes over iron rods can offer significant savings without compromising structural integrity in applications like plumbing or scaffolding.

Installation Methods and Requirements

Iron pipe installation requires threaded joints or welding to ensure leak-proof connections, often involving cutting, threading machines, and sealing compounds to meet plumbing or structural standards. Iron rod installation typically involves anchoring or embedding in concrete, using clamps, welding, or mechanical fasteners for reinforcement in construction frameworks. Both require precise measurements and adherence to building codes to maintain structural integrity and safety.

Corrosion Resistance and Maintenance

Iron pipes generally exhibit higher corrosion resistance due to protective coatings such as galvanization, which shield them from rust and extend their lifespan. In contrast, iron rods lack such coatings and require frequent maintenance like painting or applying anti-rust treatments to prevent surface degradation. Proper maintenance of iron rods is crucial to avoid structural weakening caused by corrosion, especially in outdoor or moist environments.

Sizing and Customization Options

Iron pipes are typically measured by their diameter and wall thickness, which are standardized for fluid transport applications, while iron rods are sized by their diameter and length for structural uses. Pipes offer limited customization beyond standard sizes and threading, whereas iron rods can be custom-cut, bent, and fabricated to specific dimensions and shapes. Choosing between iron pipes and rods depends on the precise sizing requirements and the flexibility needed for the intended project.

Environmental Impact and Recycling

Iron pipes and iron rods differ significantly in their environmental impact and recyclability due to their manufacturing processes and usage. Iron pipes, often coated with protective layers to resist corrosion, may involve chemical treatments that complicate recycling, whereas iron rods are typically solid and easier to recycle with lower environmental costs. Recycling both materials conserves natural resources and reduces energy consumption, but iron rods generally offer a more straightforward recycling process with minimal environmental hazards.

Iron Pipe vs Iron Rod Infographic

materialdif.com

materialdif.com