Alloyed iron combines pure iron with other elements like carbon, chromium, or nickel to enhance strength, corrosion resistance, and durability, making it ideal for construction and manufacturing. Pure iron, in contrast, offers high magnetic permeability and excellent ductility but lacks the hardness and wear resistance required for many industrial applications. Choosing between alloyed iron and pure iron depends on the specific performance requirements such as tensile strength and environmental exposure.

Table of Comparison

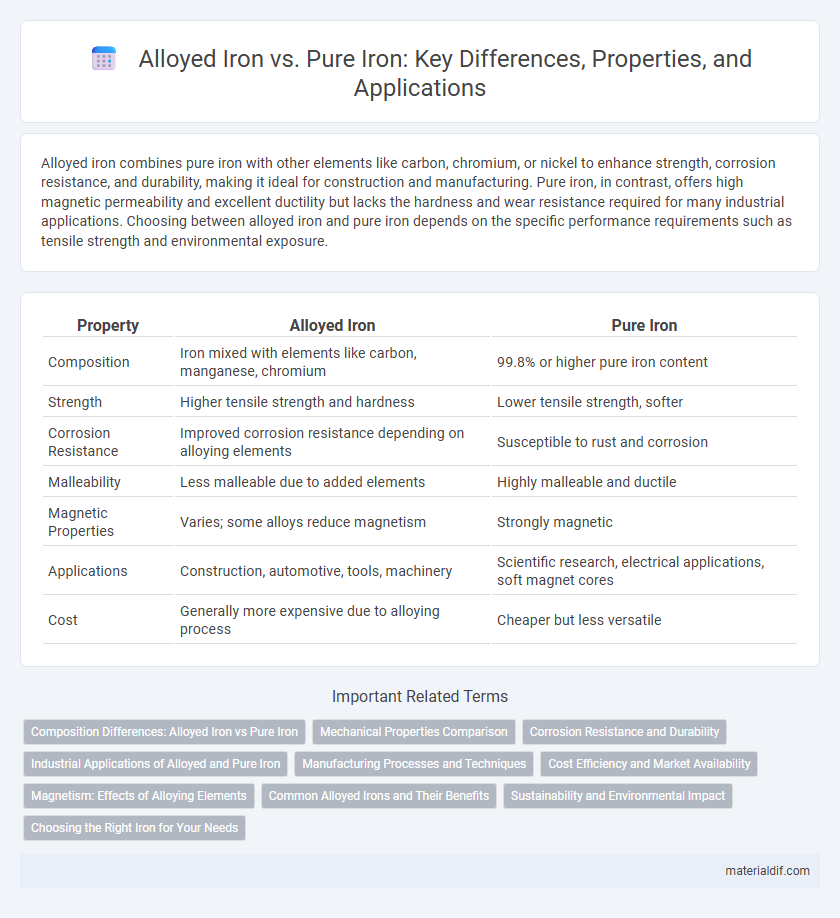

| Property | Alloyed Iron | Pure Iron |

|---|---|---|

| Composition | Iron mixed with elements like carbon, manganese, chromium | 99.8% or higher pure iron content |

| Strength | Higher tensile strength and hardness | Lower tensile strength, softer |

| Corrosion Resistance | Improved corrosion resistance depending on alloying elements | Susceptible to rust and corrosion |

| Malleability | Less malleable due to added elements | Highly malleable and ductile |

| Magnetic Properties | Varies; some alloys reduce magnetism | Strongly magnetic |

| Applications | Construction, automotive, tools, machinery | Scientific research, electrical applications, soft magnet cores |

| Cost | Generally more expensive due to alloying process | Cheaper but less versatile |

Composition Differences: Alloyed Iron vs Pure Iron

Alloyed iron contains a mixture of elements such as carbon, manganese, chromium, and nickel, which significantly enhance its mechanical properties and corrosion resistance compared to pure iron. Pure iron is composed almost entirely of iron atoms with minimal impurities, resulting in a softer and more ductile metal with lower strength. The addition of alloying elements in alloyed iron creates a complex microstructure that improves hardness, tensile strength, and overall durability for industrial applications.

Mechanical Properties Comparison

Alloyed iron exhibits enhanced mechanical properties compared to pure iron, including higher tensile strength, improved hardness, and better wear resistance due to the presence of elements like carbon, chromium, and nickel. Pure iron, while exhibiting excellent ductility and magnetic properties, is relatively soft and prone to deformation under stress. The incorporation of alloying elements significantly increases the iron's ability to withstand mechanical loads and extend its service life in industrial applications.

Corrosion Resistance and Durability

Alloyed iron exhibits enhanced corrosion resistance compared to pure iron due to the presence of elements such as chromium, nickel, and molybdenum, which form a protective oxide layer that inhibits rust formation. The durability of alloyed iron surpasses that of pure iron because the alloying elements improve mechanical properties, resistance to wear, and environmental degradation. These characteristics make alloyed iron a preferred choice in harsh or corrosive environments where long-term structural integrity is critical.

Industrial Applications of Alloyed and Pure Iron

Alloyed iron, such as steel and cast iron, offers enhanced strength, corrosion resistance, and durability, making it ideal for automotive, construction, and heavy machinery applications. Pure iron, while softer and more ductile, serves as a crucial raw material in manufacturing magnets, electrical components, and various chemical industries due to its high magnetic permeability and chemical reactivity. Industrial applications heavily favor alloyed iron when structural integrity and wear resistance are critical, while pure iron remains valuable for specialized uses requiring high purity and magnetic properties.

Manufacturing Processes and Techniques

Alloyed iron is produced by combining pure iron with elements such as carbon, chromium, or nickel through processes like casting, forging, and powder metallurgy to enhance its mechanical properties and corrosion resistance. Pure iron manufacturing primarily involves smelting followed by refining methods such as electrolysis or hydrogen reduction to achieve high purity with minimal impurities. Advanced techniques like vacuum induction melting and controlled atmosphere heat treatment are employed to precisely tailor the microstructure and performance characteristics of both alloyed and pure iron products.

Cost Efficiency and Market Availability

Alloyed iron, containing elements like carbon and chromium, offers increased strength and corrosion resistance, making it more cost-efficient in long-term applications despite higher initial costs. Pure iron has lower material costs and simpler processing but lacks durability, leading to higher maintenance expenses and limited industrial use. Market availability favors alloyed iron due to its widespread demand in construction, automotive, and manufacturing sectors, whereas pure iron remains niche with restricted commercial distribution.

Magnetism: Effects of Alloying Elements

Alloyed iron exhibits altered magnetic properties compared to pure iron due to the presence of alloying elements like carbon, nickel, and chromium, which disrupt the iron's crystal lattice and affect electron spin alignment. Pure iron is highly magnetic with a strong ferromagnetic response, whereas alloying elements can reduce magnetization by introducing non-magnetic phases or causing magnetic domain distortion. The specific magnetic behavior depends on the type and concentration of alloying elements, impacting applications in electromagnetic devices and industrial magnetic materials.

Common Alloyed Irons and Their Benefits

Common alloyed irons include steel variants such as carbon steel, stainless steel, and tool steel, each enhanced with elements like carbon, chromium, and vanadium to improve strength, corrosion resistance, and hardness. These alloying elements enable alloyed irons to outperform pure iron in durability and applications requiring specific mechanical properties. As a result, alloyed irons are preferred in construction, automotive manufacturing, and tool production for their superior performance and longevity.

Sustainability and Environmental Impact

Alloyed iron, containing elements such as carbon, chromium, and nickel, offers enhanced durability and corrosion resistance, reducing the frequency of replacement and associated resource consumption compared to pure iron. The manufacturing process of alloyed iron can be more energy-intensive and may involve toxic additives, but its extended lifespan contributes to lower overall environmental impact through reduced waste generation. Pure iron, although simpler to recycle and less chemically complex, corrodes faster, necessitating more frequent production cycles that increase raw material extraction and greenhouse gas emissions.

Choosing the Right Iron for Your Needs

Alloyed iron contains elements like carbon, chromium, and nickel that enhance strength, corrosion resistance, and hardness, making it ideal for construction and manufacturing applications requiring durability. Pure iron, with its high ductility and magnetic properties, is best suited for applications needing excellent malleability and magnetic performance, such as electromagnets and transformers. Selecting the appropriate type depends on the mechanical properties required, environmental exposure, and specific use cases.

Alloyed Iron vs Pure Iron Infographic

materialdif.com

materialdif.com