Forging iron involves heating the metal until it becomes malleable and then shaping it using hammering or pressing, resulting in stronger and more durable iron products. Stamping iron, on the other hand, uses high-pressure dies to cut or form the metal without heating, allowing for faster production but often yielding less robust pieces. Choosing forging over stamping enhances structural integrity, making it ideal for applications requiring toughness and longevity.

Table of Comparison

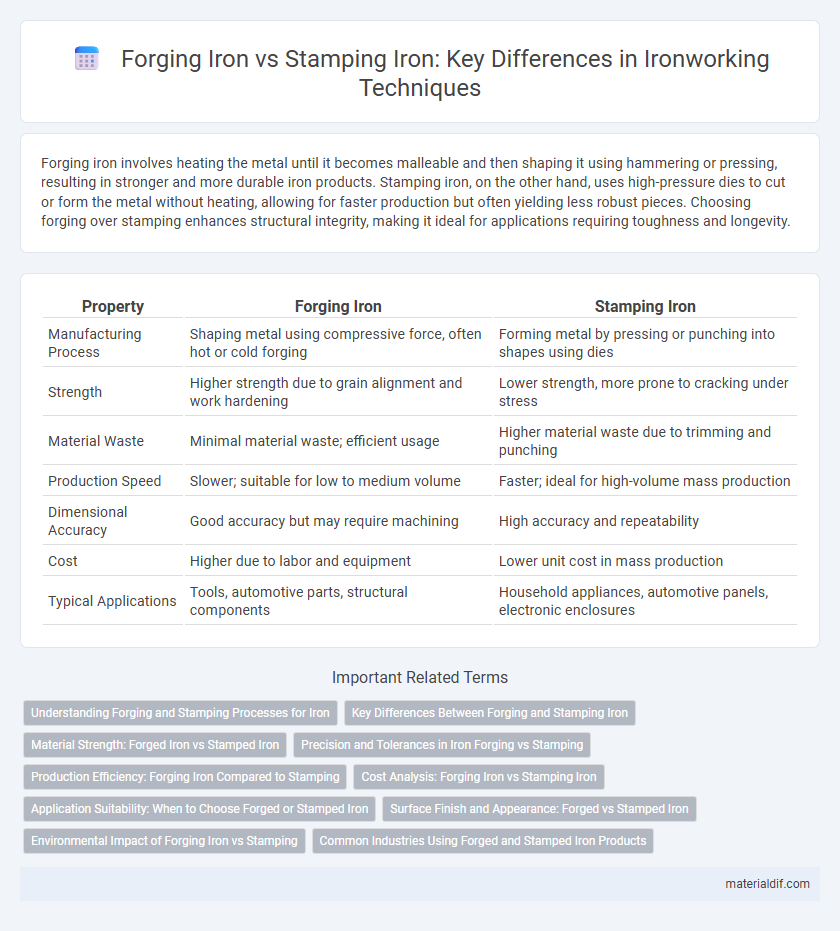

| Property | Forging Iron | Stamping Iron |

|---|---|---|

| Manufacturing Process | Shaping metal using compressive force, often hot or cold forging | Forming metal by pressing or punching into shapes using dies |

| Strength | Higher strength due to grain alignment and work hardening | Lower strength, more prone to cracking under stress |

| Material Waste | Minimal material waste; efficient usage | Higher material waste due to trimming and punching |

| Production Speed | Slower; suitable for low to medium volume | Faster; ideal for high-volume mass production |

| Dimensional Accuracy | Good accuracy but may require machining | High accuracy and repeatability |

| Cost | Higher due to labor and equipment | Lower unit cost in mass production |

| Typical Applications | Tools, automotive parts, structural components | Household appliances, automotive panels, electronic enclosures |

Understanding Forging and Stamping Processes for Iron

Forging iron involves heating the metal until it becomes malleable and then shaping it using compressive forces, which enhances the material's strength and durability through refined grain structure. Stamping iron utilizes high-pressure dies to cut or form the metal into precise shapes without altering its internal properties, making it ideal for mass production of thin, detailed components. Understanding these processes reveals that forging is preferred for applications requiring toughness and resilience, while stamping excels in creating consistent, intricate parts efficiently.

Key Differences Between Forging and Stamping Iron

Forging iron involves heating the metal until it is malleable and then shaping it using compressive forces, resulting in enhanced strength and structural integrity due to grain refinement. Stamping iron uses a die to cut or shape cold metal sheets through high-pressure pressing, allowing high-volume production with precise and repeatable shapes but limited structural strength. The key differences lie in the heat application, mechanical properties, and production scalability, with forging providing superior durability and stamping favoring efficiency and detail.

Material Strength: Forged Iron vs Stamped Iron

Forged iron exhibits superior material strength due to the heating and hammering process that aligns its grain structure, resulting in enhanced toughness and durability. Stamped iron, produced by pressing metal sheets into shape, generally has a weaker grain orientation, making it more prone to deformation under stress. This fundamental difference means forged iron is preferred for applications requiring high mechanical strength and impact resistance.

Precision and Tolerances in Iron Forging vs Stamping

Iron forging offers superior precision and tighter tolerances compared to stamping due to the controlled deformation process and fine-grain structure achieved during hot working. Forging minimizes internal defects and enhances mechanical properties, resulting in components with consistent dimensions and higher strength. In contrast, stamping typically involves higher material stress and less dimensional accuracy, limiting its use in applications requiring stringent tolerance control.

Production Efficiency: Forging Iron Compared to Stamping

Forging iron involves shaping metal through localized compressive forces, resulting in higher strength and durability but requiring longer production times and more energy consumption. Stamping iron uses high-speed mechanical presses to cut or shape metal sheets efficiently, offering greater production speed and lower unit costs for high-volume manufacturing. While forging delivers superior mechanical properties, stamping excels in production efficiency, making it ideal for mass-produced iron components.

Cost Analysis: Forging Iron vs Stamping Iron

Forging iron typically incurs higher initial costs due to expensive machinery and higher energy consumption, but results in superior strength and durability, reducing long-term maintenance expenses. Stamping iron offers lower upfront costs and faster production rates, making it more economical for large-scale manufacturing despite potential compromises in structural integrity. Evaluating cost efficiency depends on production volume, material properties required, and the specific application of the forged or stamped iron components.

Application Suitability: When to Choose Forged or Stamped Iron

Forged iron excels in applications demanding superior strength and durability, such as automotive components and heavy machinery, due to its dense, grain-oriented structure enhancing mechanical properties. Stamped iron is ideal for high-volume production of intricate, lightweight parts like appliance panels and electrical enclosures, offering cost efficiency and consistent dimensional accuracy. Choosing forged over stamped iron depends on the criticality of load-bearing requirements and precision, with forging best for structural integrity and stamping suited for complex, repetitive designs.

Surface Finish and Appearance: Forged vs Stamped Iron

Forged iron typically exhibits a smoother, more refined surface finish due to the controlled heating and hammering process that reduces surface imperfections and enhances grain structure. Stamped iron often presents a rougher texture with visible seams and irregularities from the pressing operation, affecting uniformity and aesthetic appeal. The superior surface finish of forged iron makes it more desirable for applications requiring high-quality appearance and durability.

Environmental Impact of Forging Iron vs Stamping

Forging iron involves heating and shaping metal at high temperatures, which consumes significant energy and can result in higher greenhouse gas emissions compared to stamping. Stamping iron typically uses less energy by reshaping metal at room temperature or lower heat, leading to a reduced carbon footprint and lower environmental impact. However, the choice between forging and stamping must also consider factors like material waste and production volume to optimize sustainability in iron manufacturing.

Common Industries Using Forged and Stamped Iron Products

Forged iron products are widely used in heavy-duty industries such as automotive, aerospace, and construction due to their superior strength and durability. Stamped iron components are prevalent in electronics, appliance manufacturing, and automotive interiors where precision and cost-efficiency are critical. Both forging and stamping serve distinct industrial needs, with forging preferred for high-stress applications and stamping favored for mass production of intricate parts.

Forging Iron vs Stamping Iron Infographic

materialdif.com

materialdif.com