Ferritic iron is characterized by a body-centered cubic (BCC) crystal structure that provides high magnetic permeability and moderate corrosion resistance, making it suitable for applications like automotive components and appliances. Austenitic iron, with its face-centered cubic (FCC) structure, offers superior ductility, toughness, and excellent corrosion resistance, commonly used in stainless steel manufacturing and chemical processing equipment. The distinct microstructures of ferritic and austenitic iron directly influence their mechanical properties and corrosion behavior, guiding their specific industrial applications.

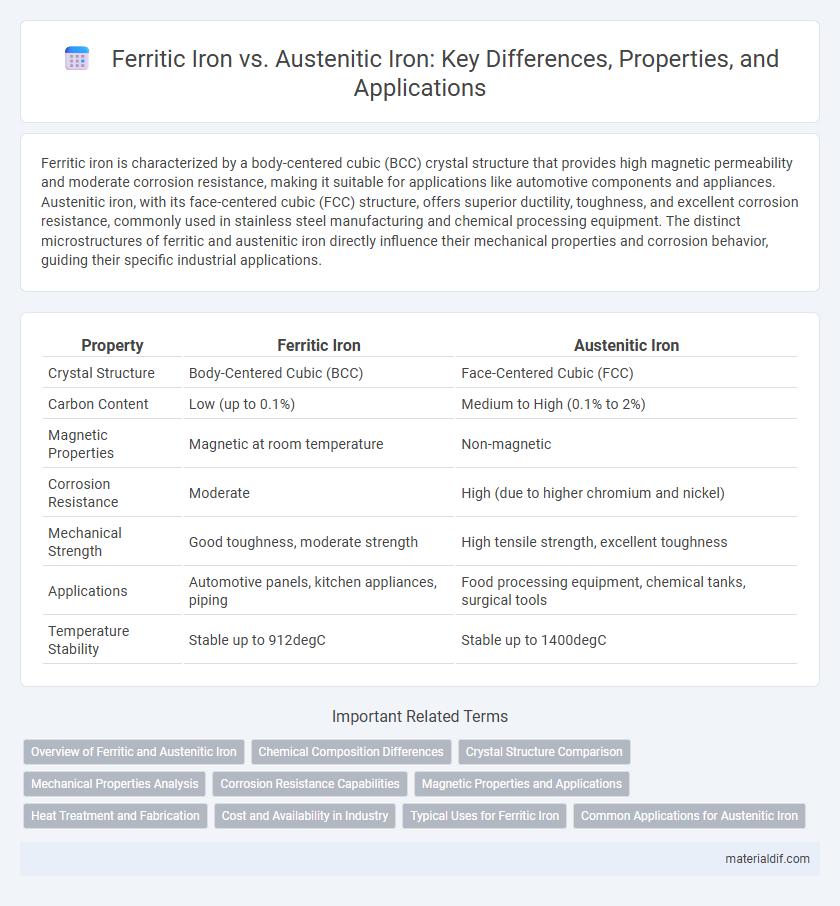

Table of Comparison

| Property | Ferritic Iron | Austenitic Iron |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Carbon Content | Low (up to 0.1%) | Medium to High (0.1% to 2%) |

| Magnetic Properties | Magnetic at room temperature | Non-magnetic |

| Corrosion Resistance | Moderate | High (due to higher chromium and nickel) |

| Mechanical Strength | Good toughness, moderate strength | High tensile strength, excellent toughness |

| Applications | Automotive panels, kitchen appliances, piping | Food processing equipment, chemical tanks, surgical tools |

| Temperature Stability | Stable up to 912degC | Stable up to 1400degC |

Overview of Ferritic and Austenitic Iron

Ferritic iron features a body-centered cubic (BCC) crystal structure, characterized by magnetic properties and high resistance to stress corrosion cracking. Austenitic iron exhibits a face-centered cubic (FCC) crystal structure, offering excellent corrosion resistance and superior toughness at low temperatures. The distinct microstructures influence mechanical performance, with ferritic grades typically used in automotive applications and austenitic grades prevalent in stainless steel production due to their enhanced ductility and corrosion resistance.

Chemical Composition Differences

Ferritic iron primarily contains a higher percentage of chromium (typically 10.5-30%) with very low carbon content (usually less than 0.1%), enhancing its magnetic properties and corrosion resistance. Austenitic iron features a significant amount of nickel (around 8-10%) and a higher carbon content (up to 0.08%), stabilizing the face-centered cubic (FCC) structure that improves toughness and ductility. The differing chemical compositions lead to distinct microstructures and performance characteristics, with ferritic iron being body-centered cubic (BCC) and austenitic iron maintaining FCC at room temperature.

Crystal Structure Comparison

Ferritic iron exhibits a body-centered cubic (BCC) crystal structure, which provides high magnetic permeability and moderate ductility, making it suitable for applications requiring magnetic properties. Austenitic iron, on the other hand, features a face-centered cubic (FCC) crystal structure, resulting in excellent corrosion resistance and superior toughness, especially at cryogenic temperatures. The difference in crystal lattice arrangements fundamentally influences their mechanical behavior, thermal stability, and magnetic characteristics.

Mechanical Properties Analysis

Ferritic iron exhibits higher magnetic permeability and better resistance to stress corrosion cracking, with a tensile strength typically ranging from 400 to 550 MPa, making it suitable for structural applications where moderate strength and corrosion resistance are required. Austenitic iron, characterized by its face-centered cubic (FCC) crystal structure, offers superior ductility and toughness, with tensile strength commonly between 600 and 900 MPa, and excellent corrosion resistance especially in cryogenic environments. The comparison highlights ferritic iron's advantage in magnetic applications and cost-efficiency, while austenitic iron's enhanced mechanical properties and corrosion resistance make it ideal for demanding industrial uses.

Corrosion Resistance Capabilities

Ferritic iron, characterized by a body-centered cubic (BCC) crystal structure, offers moderate corrosion resistance, particularly in reducing environments, due to its lower nickel content and higher chromium levels that help form a stable oxide layer. Austenitic iron, with a face-centered cubic (FCC) structure enriched with nickel and chromium, exhibits superior corrosion resistance, especially against oxidizing and harsh chemical conditions, making it ideal for marine and chemical processing applications. The enhanced passive film stability in austenitic variants significantly reduces susceptibility to pitting and stress corrosion cracking compared to ferritic types.

Magnetic Properties and Applications

Ferritic iron exhibits strong magnetic properties due to its body-centered cubic (BCC) crystal structure, making it ideal for applications such as transformers, electric motors, and magnetic cores where magnetic permeability is critical. Austenitic iron, characterized by its face-centered cubic (FCC) structure, is generally non-magnetic but offers superior corrosion resistance and ductility, commonly used in stainless steel grades for chemical processing, kitchenware, and structural applications. The distinct magnetic behavior of ferritic and austenitic iron phases directly influences their suitability in electromagnetic and structural environments.

Heat Treatment and Fabrication

Ferritic iron, characterized by a body-centered cubic (BCC) crystal structure, exhibits excellent heat treatment response with improved magnetic properties and enhanced resistance to stress corrosion cracking but lower ductility compared to austenitic iron. Austenitic iron, possessing a face-centered cubic (FCC) structure, offers superior toughness and corrosion resistance, requiring solution annealing and cryogenic treatments to maintain its non-magnetic state and optimize mechanical performance. Fabrication of ferritic iron typically includes cold working and tempering to increase strength, while austenitic iron demands precise control of heat treatment parameters to retain its ductility and prevent carbide precipitation during welding.

Cost and Availability in Industry

Ferritic iron alloys generally cost less than austenitic variants due to their lower nickel content and simpler manufacturing processes, making them more economically viable for large-scale industrial use. Ferritic steels are widely available and preferred in applications requiring magnetic properties and moderate corrosion resistance, whereas austenitic iron, enriched with nickel and chromium, offers superior corrosion resistance but at a higher price and limited supply. Industries prioritize ferritic iron when cost-efficiency and bulk availability are crucial, while austenitic iron suits environments demanding enhanced durability despite increased expense.

Typical Uses for Ferritic Iron

Ferritic iron, characterized by a body-centered cubic (BCC) crystal structure and magnetic properties, is commonly used in automotive exhaust systems, industrial equipment, and kitchen utensils due to its excellent corrosion resistance and high-temperature stability. It often serves in applications requiring good ductility and moderate strength without the need for high alloying elements. Ferritic iron is preferred in scenarios where thermal conductivity and resistance to stress corrosion cracking are critical.

Common Applications for Austenitic Iron

Austenitic iron, known for its excellent corrosion resistance and high ductility, is commonly used in kitchen utensils, chemical processing equipment, and architectural structures exposed to harsh environmental conditions. Its non-magnetic properties and superior toughness make it ideal for food processing industries and medical instruments. The alloy's ability to withstand extreme temperatures also finds applications in heat exchangers and cryogenic vessels.

Ferritic Iron vs Austenitic Iron Infographic

materialdif.com

materialdif.com