Grey iron contains graphite flakes that provide excellent machinability, vibration damping, and thermal conductivity, making it ideal for engine blocks and pipes. White iron features a hard, crystalline structure with cementite, offering high wear resistance but less machinability, commonly used for abrasion-resistant surfaces. Choosing between grey and white iron depends on the balance needed between hardness, strength, and ease of manufacturing.

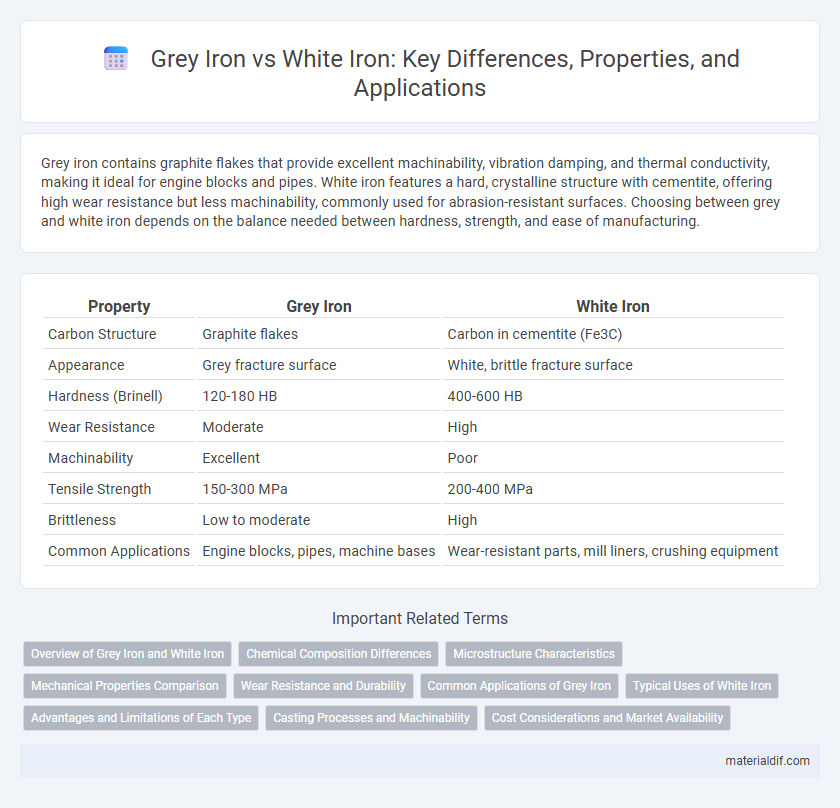

Table of Comparison

| Property | Grey Iron | White Iron |

|---|---|---|

| Carbon Structure | Graphite flakes | Carbon in cementite (Fe3C) |

| Appearance | Grey fracture surface | White, brittle fracture surface |

| Hardness (Brinell) | 120-180 HB | 400-600 HB |

| Wear Resistance | Moderate | High |

| Machinability | Excellent | Poor |

| Tensile Strength | 150-300 MPa | 200-400 MPa |

| Brittleness | Low to moderate | High |

| Common Applications | Engine blocks, pipes, machine bases | Wear-resistant parts, mill liners, crushing equipment |

Overview of Grey Iron and White Iron

Grey iron features a graphitic microstructure that provides excellent machinability, vibration damping, and thermal conductivity, commonly used in engine blocks and pipes. White iron contains a hard, brittle cementite phase, resulting in high wear resistance and hardness, suitable for applications like crushers and grinding mills. The key differences lie in carbon content distribution, with grey iron having free carbon as graphite and white iron having carbon combined as cementite.

Chemical Composition Differences

Grey iron contains 2.5-4% carbon predominantly in the form of graphite flakes, which imparts excellent machinability and vibration damping properties. White iron features a lower carbon content of 1.8-3.6%, with carbon mostly combined as iron carbide (cementite), resulting in a harder and more wear-resistant material. The presence of silicon, typically 1-3% in grey iron, promotes graphite formation, whereas white iron has less silicon, favoring cementite development and a white fracture surface.

Microstructure Characteristics

Grey iron exhibits a microstructure characterized by flake graphite dispersed within a pearlitic or ferritic matrix, which imparts excellent damping properties and machinability. White iron contains a microstructure dominated by cementite (Fe3C) and pearlite, with carbon present as iron carbide instead of graphite, resulting in high hardness and brittleness. These distinct microstructures directly influence the mechanical behavior and wear resistance of each iron type.

Mechanical Properties Comparison

Grey iron exhibits excellent damping capacity, high compressive strength, and good machinability due to its graphite flake microstructure, making it suitable for automotive engine blocks and pipes. White iron contains cementite instead of graphite, resulting in superior hardness and wear resistance but lower ductility and impact strength, commonly used in abrasion-resistant applications like liners and crushers. The choice between grey and white iron depends on the balance needed between hardness, brittleness, and machinability for specific mechanical demands.

Wear Resistance and Durability

Grey iron exhibits superior wear resistance and durability due to its graphite flake microstructure, which provides excellent damping properties and reduces friction during operation. White iron, characterized by its hard cementite matrix, offers higher hardness but is more brittle, making it less durable under impact or shock loading. For applications requiring sustained wear resistance and toughness, grey iron is generally preferred over white iron.

Common Applications of Grey Iron

Grey iron, known for its excellent machinability and vibration damping properties, is widely used in automotive engine blocks, machinery bases, and pipe fittings. Its graphite flakes provide wear resistance and thermal conductivity, making it ideal for brake discs, pumps, and valve bodies. The popularity of grey iron in construction and heavy equipment highlights its strength and durability under stress.

Typical Uses of White Iron

White iron is typically used in applications requiring high wear resistance and durability, such as in the manufacturing of grinding balls, mill liners, and wear-resistant liners in cement and mining industries. Its hard, brittle nature makes it ideal for situations where abrasion and impact are prevalent, including in coal crushers, shot-blasting equipment, and pump liners. The distinctive carbide microstructure of white iron enhances its resistance to abrasive wear, making it suitable for heavy-duty industrial components.

Advantages and Limitations of Each Type

Grey iron offers superior machinability and excellent damping properties due to its flake graphite structure, making it ideal for automotive engine blocks and machinery bases. Its limitations include lower tensile strength and brittleness, which reduce impact resistance. White iron, characterized by its hard and wear-resistant cementite microstructure, excels in applications requiring high abrasion resistance but suffers from poor machinability and higher brittleness.

Casting Processes and Machinability

Grey iron, characterized by its flake graphite microstructure, offers excellent machinability due to its ability to easily shear and break chips during casting processes, resulting in smoother finishes and reduced tool wear. White iron, with its carbide-rich microstructure, presents challenges in casting because of its hardness and brittleness, making machining difficult and often requiring specialized cutting tools to prevent rapid tool degradation. The choice between grey and white iron casting hinges on the balance between machinability and wear resistance, where grey iron is preferred for ease of post-casting machining and white iron for superior abrasion resistance.

Cost Considerations and Market Availability

Grey iron typically offers lower production costs due to its simpler casting process and widespread availability of raw materials, making it a cost-effective choice for large-scale manufacturing. White iron, with its harder microstructure and more complex heat treatment requirements, generally incurs higher processing expenses and is less common in the market. Market availability favors grey iron for applications like automotive and pipe fittings, while white iron is more specialized and often reserved for wear-resistant components, reflecting their distinct cost and supply dynamics.

Grey Iron vs White Iron Infographic

materialdif.com

materialdif.com