Iron powder offers superior reactivity and is widely used in powder metallurgy and additive manufacturing processes, while iron ore serves as the primary raw material extracted from mines for smelting and refining into usable iron. The fine particle size of iron powder facilitates rapid chemical reactions and precise engineering applications, contrasting with the bulk, mineral-rich composition of iron ore that requires extensive processing. Choosing between iron powder and iron ore depends on the intended industrial use, with powder favored for advanced manufacturing and ore essential for large-scale iron production.

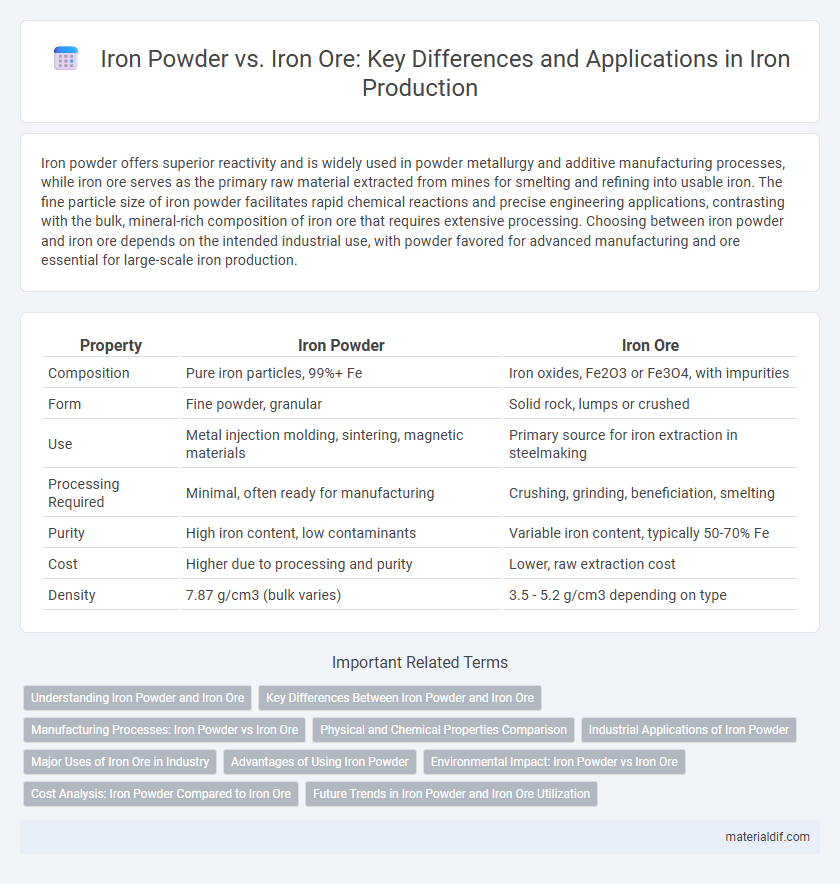

Table of Comparison

| Property | Iron Powder | Iron Ore |

|---|---|---|

| Composition | Pure iron particles, 99%+ Fe | Iron oxides, Fe2O3 or Fe3O4, with impurities |

| Form | Fine powder, granular | Solid rock, lumps or crushed |

| Use | Metal injection molding, sintering, magnetic materials | Primary source for iron extraction in steelmaking |

| Processing Required | Minimal, often ready for manufacturing | Crushing, grinding, beneficiation, smelting |

| Purity | High iron content, low contaminants | Variable iron content, typically 50-70% Fe |

| Cost | Higher due to processing and purity | Lower, raw extraction cost |

| Density | 7.87 g/cm3 (bulk varies) | 3.5 - 5.2 g/cm3 depending on type |

Understanding Iron Powder and Iron Ore

Iron powder is a fine particulate form of iron produced through atomization, reduction, or electrolysis processes, offering higher surface area and reactivity compared to iron ore. In contrast, iron ore is a naturally occurring mineral substance, primarily hematite or magnetite, containing iron oxides that require extraction and beneficiation before use in steelmaking. Understanding the physical and chemical differences between iron powder and iron ore is essential for applications in metallurgy, additive manufacturing, and chemical synthesis.

Key Differences Between Iron Powder and Iron Ore

Iron powder consists of fine particles produced through processes such as atomization or reduction, offering high surface area and reactivity, making it ideal for powder metallurgy and catalyst applications. Iron ore is a naturally occurring mineral, primarily composed of iron oxides like hematite and magnetite, serving as the principal raw material for iron extraction in blast furnaces. Key differences include physical form, production methods, and usage, with iron powder enabling precise manufacturing processes while iron ore requires smelting to obtain metallic iron.

Manufacturing Processes: Iron Powder vs Iron Ore

Iron powder is produced through atomization, reduction, or electrolysis processes that allow precise particle size control for powder metallurgy applications. Iron ore undergoes extraction, crushing, grinding, and smelting to produce pig iron or steel in blast furnaces. The manufacturing of iron powder emphasizes fine particle distribution, while iron ore processing focuses on bulk metal extraction and purification.

Physical and Chemical Properties Comparison

Iron powder exhibits a higher surface area and greater reactivity compared to iron ore due to its fine particulate form, facilitating faster chemical reactions such as oxidation and reduction. Iron ore primarily consists of iron oxides with varying impurities, displaying lower purity and coarser physical texture, which impacts its melting point and conductivity. The physical properties of iron powder, including its fine granularity and enhanced compressibility, make it suitable for powder metallurgy, whereas iron ore's bulk structure necessitates smelting for iron extraction.

Industrial Applications of Iron Powder

Iron powder plays a critical role in industrial applications such as powder metallurgy, magnetic materials, and friction components, providing superior density control and homogeneity compared to iron ore. Unlike iron ore, which requires extensive processing and refining, iron powder can be directly used in manufacturing processes like sintering and additive manufacturing, enhancing efficiency and reducing waste. Its fine particle size and high purity enable precise shaping, improved mechanical properties, and better performance in automotive, aerospace, and electronics industries.

Major Uses of Iron Ore in Industry

Iron ore is primarily used in the steelmaking industry as the essential raw material for producing pig iron, which is further refined into steel. Major industries such as construction, automotive, and manufacturing rely heavily on iron ore-derived steel for building infrastructure, vehicles, and machinery. The high iron content and ease of processing make iron ore a critical component for industrial applications requiring durability and strength.

Advantages of Using Iron Powder

Iron powder offers enhanced surface area and reactivity compared to iron ore, enabling faster chemical reactions and improved sintering efficiency in manufacturing processes. Its fine granularity allows precise control over composition and density in powder metallurgy, leading to superior mechanical properties and reduced material waste. Iron powder's uniform particle size distribution also results in consistent quality and better performance in applications such as magnetic materials and additive manufacturing.

Environmental Impact: Iron Powder vs Iron Ore

Iron powder generally has a lower environmental impact than iron ore due to its production processes, which consume less energy and generate fewer emissions. Iron ore mining involves extensive land disruption, habitat loss, and significant carbon footprints from extraction, transportation, and processing activities. Processing iron powder often utilizes recycled materials, reducing the reliance on raw ore extraction and minimizing environmental degradation.

Cost Analysis: Iron Powder Compared to Iron Ore

Iron powder often incurs higher production costs due to extensive processing, including atomization or reduction methods, whereas iron ore offers a more cost-effective raw material for bulk steelmaking. The value chain of iron powder involves additional refining, alloying, and quality control which significantly adds to the overall expense compared to primarily mined and minimally processed iron ore. For industries prioritizing cost efficiency, iron ore remains the preferred feedstock, while iron powder justifies its premium pricing in specialized applications such as additive manufacturing and precision metallurgy.

Future Trends in Iron Powder and Iron Ore Utilization

Iron powder is increasingly favored for advanced manufacturing and additive processes due to its high purity and consistent particle size, driving growth in sectors like automotive and aerospace. Iron ore remains a crucial raw material but faces challenges from environmental regulations and the push for more sustainable mining practices. Innovations in iron powder production, such as hydrogen reduction, are expected to enhance efficiency and reduce carbon emissions, shaping the future landscape of iron utilization.

Iron Powder vs Iron Ore Infographic

materialdif.com

materialdif.com