Powder coating offers superior durability and resistance to chipping, scratching, and fading compared to traditional paint coating on iron pets. It creates a thicker, more uniform layer that protects against rust and weather exposure, enhancing the longevity of iron products. Maintenance is easier with powder-coated surfaces as they are less prone to peeling and require less frequent touch-ups than painted coatings.

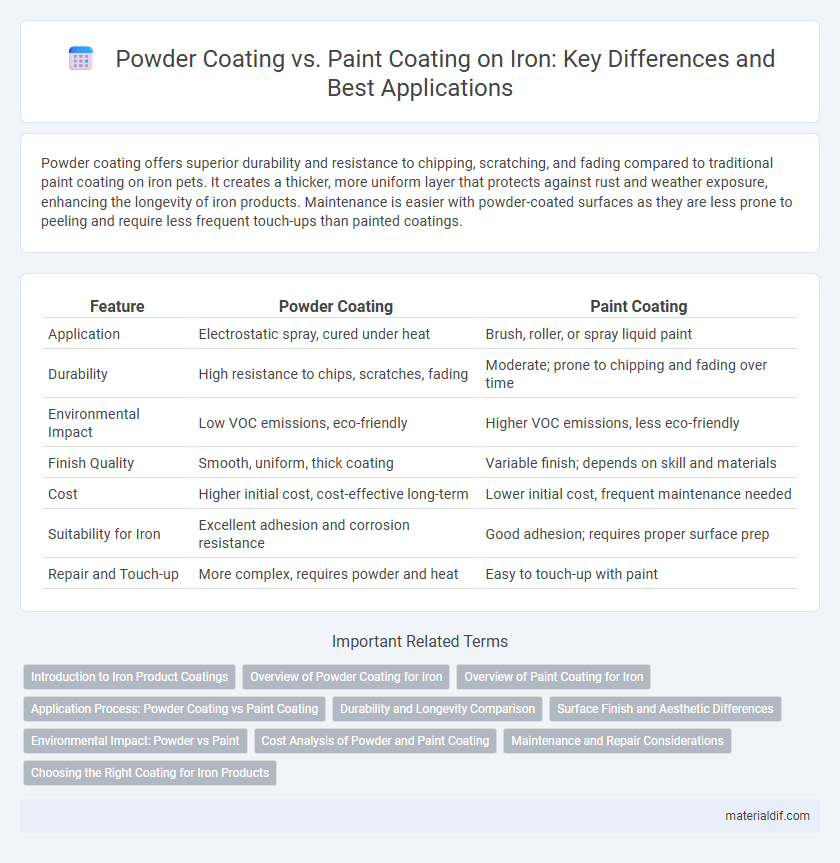

Table of Comparison

| Feature | Powder Coating | Paint Coating |

|---|---|---|

| Application | Electrostatic spray, cured under heat | Brush, roller, or spray liquid paint |

| Durability | High resistance to chips, scratches, fading | Moderate; prone to chipping and fading over time |

| Environmental Impact | Low VOC emissions, eco-friendly | Higher VOC emissions, less eco-friendly |

| Finish Quality | Smooth, uniform, thick coating | Variable finish; depends on skill and materials |

| Cost | Higher initial cost, cost-effective long-term | Lower initial cost, frequent maintenance needed |

| Suitability for Iron | Excellent adhesion and corrosion resistance | Good adhesion; requires proper surface prep |

| Repair and Touch-up | More complex, requires powder and heat | Easy to touch-up with paint |

Introduction to Iron Product Coatings

Iron product coatings enhance durability and corrosion resistance by creating a protective layer on the metal surface. Powder coating, a dry finishing process, offers superior adhesion and uniform coverage with increased resistance to chipping, fading, and scratching compared to traditional paint coatings. Paint coating, although easier to apply, often requires multiple layers and more frequent maintenance to protect iron from rust and environmental damage.

Overview of Powder Coating for Iron

Powder coating on iron creates a durable, corrosion-resistant finish through the application of electrostatically charged powder, which is then cured under heat to form a hard layer. This method offers superior resistance to chipping, scratching, and fading compared to traditional paint coatings, making it ideal for iron surfaces exposed to harsh environments. Powder coating is also environmentally friendly, producing less hazardous waste and utilizing no solvents, enhancing sustainability in iron finishing processes.

Overview of Paint Coating for Iron

Paint coating for iron provides a protective barrier that prevents rust and corrosion by sealing the metal surface from moisture and oxygen exposure. It offers versatile aesthetic options with various colors and finishes, enhancing the appearance of iron structures and components. Regular maintenance of paint coatings ensures long-lasting durability and effectiveness in industrial, architectural, and automotive applications.

Application Process: Powder Coating vs Paint Coating

Powder coating involves applying a dry powder electrostatically to iron surfaces, followed by curing under heat to form a durable layer, whereas paint coating requires spraying or brushing liquid paint that dries through solvent evaporation. Powder coating provides a thicker, more even protection with minimal overspray and waste compared to paint coating, which may require multiple layers and longer drying times. The powder coating process is generally faster with fewer environmental hazards, while paint coating offers easier touch-up and color variations.

Durability and Longevity Comparison

Powder coating on iron offers superior durability compared to traditional paint coatings, providing resistance to chipping, scratching, and fading under harsh environmental conditions. The electrostatic application process creates a thicker, more even layer that enhances corrosion protection and extends the lifespan of iron surfaces significantly. Paint coatings typically require more frequent maintenance and touch-ups due to their susceptibility to wear and exposure to moisture and UV rays.

Surface Finish and Aesthetic Differences

Powder coating on iron provides a thicker, more durable finish with excellent resistance to chipping, fading, and corrosion, resulting in a smoother and more uniform surface appearance. Paint coating offers a wider range of colors and gloss levels but tends to be thinner and more susceptible to scratches and environmental wear over time. The textured and matte finishes achievable with powder coating create a modern, flawless aesthetic, whereas paint coating can deliver more traditional, glossy effects with variable surface textures.

Environmental Impact: Powder vs Paint

Powder coating on iron significantly reduces environmental impact by emitting fewer volatile organic compounds (VOCs) compared to traditional paint coatings. Unlike paint, powder coating generates minimal hazardous waste due to its overspray recycling capability, enhancing sustainability. The curing process of powder coatings uses less energy and releases no harmful solvents, making it a greener option for corrosion protection on iron surfaces.

Cost Analysis of Powder and Paint Coating

Powder coating on iron surfaces typically incurs higher initial equipment costs but offers lower long-term expenses due to minimal material waste and longer durability compared to traditional paint coating. Paint coating requires frequent reapplications and generates more volatile organic compounds, raising maintenance and environmental compliance costs over time. Considering lifecycle costs, powder coating proves more cost-effective for industrial-scale iron applications despite higher upfront investment.

Maintenance and Repair Considerations

Powder coating on iron offers superior durability, resisting chipping, scratching, and fading better than traditional paint coatings, which minimizes maintenance needs over time. Repairing powder-coated iron surfaces typically requires professional intervention to ensure color matching and finish integrity, whereas paint coatings allow for easier spot repairs and touch-ups by DIY methods. Maintenance on painted iron involves regular inspections for rust and more frequent reapplications, while powder coating extends intervals between upkeep due to its robust protective layer.

Choosing the Right Coating for Iron Products

Powder coating offers superior durability and corrosion resistance for iron products, making it ideal for outdoor and high-wear applications compared to traditional paint coatings. It provides a thicker, more uniform finish that resists chipping, scratching, and fading, extending the lifespan of iron surfaces. Paint coatings allow for easier touch-ups and a wider variety of color options, but generally require more maintenance and frequent reapplication on iron materials.

Powder Coating vs Paint Coating Infographic

materialdif.com

materialdif.com