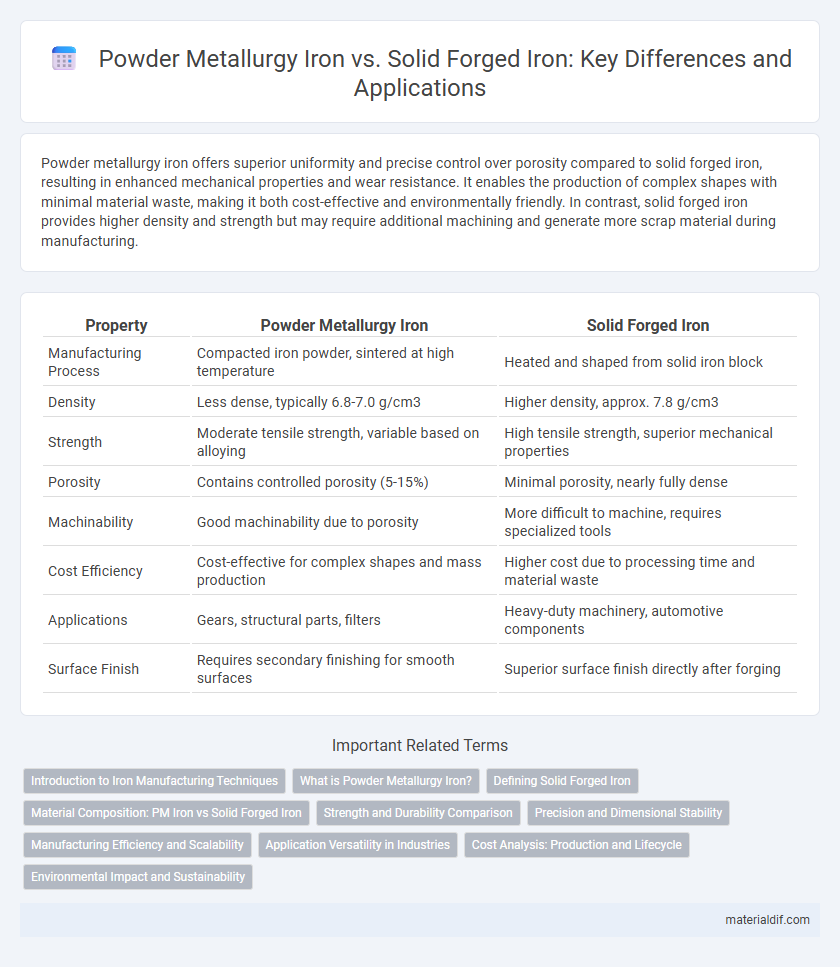

Powder metallurgy iron offers superior uniformity and precise control over porosity compared to solid forged iron, resulting in enhanced mechanical properties and wear resistance. It enables the production of complex shapes with minimal material waste, making it both cost-effective and environmentally friendly. In contrast, solid forged iron provides higher density and strength but may require additional machining and generate more scrap material during manufacturing.

Table of Comparison

| Property | Powder Metallurgy Iron | Solid Forged Iron |

|---|---|---|

| Manufacturing Process | Compacted iron powder, sintered at high temperature | Heated and shaped from solid iron block |

| Density | Less dense, typically 6.8-7.0 g/cm3 | Higher density, approx. 7.8 g/cm3 |

| Strength | Moderate tensile strength, variable based on alloying | High tensile strength, superior mechanical properties |

| Porosity | Contains controlled porosity (5-15%) | Minimal porosity, nearly fully dense |

| Machinability | Good machinability due to porosity | More difficult to machine, requires specialized tools |

| Cost Efficiency | Cost-effective for complex shapes and mass production | Higher cost due to processing time and material waste |

| Applications | Gears, structural parts, filters | Heavy-duty machinery, automotive components |

| Surface Finish | Requires secondary finishing for smooth surfaces | Superior surface finish directly after forging |

Introduction to Iron Manufacturing Techniques

Powder metallurgy iron involves compacting iron powder into a desired shape and sintering it to achieve solid form, offering precise control over porosity and microstructure. Solid forged iron is produced by heating and mechanically deforming solid iron billets, resulting in dense, strong components with superior toughness. These distinct manufacturing techniques influence the mechanical properties and application suitability of iron components in industries like automotive and construction.

What is Powder Metallurgy Iron?

Powder Metallurgy Iron is produced by compressing iron powder and sintering it under controlled temperature to form a solid mass, resulting in uniform microstructure and precise dimensional control. This process enhances material properties such as wear resistance and strength while reducing waste and machining requirements compared to solid forged iron. Powder Metallurgy Iron is ideal for complex shapes and high-volume production where consistent quality and performance are critical.

Defining Solid Forged Iron

Solid forged iron is a metal formed by heating a solid billet and shaping it through compressive forces like hammering or pressing, resulting in enhanced strength and grain structure alignment. Unlike powder metallurgy iron, which is made by compacting and sintering iron powders, solid forged iron boasts superior mechanical properties due to its dense, continuous grain structure. This forging process makes solid forged iron ideal for critical applications demanding high durability and toughness.

Material Composition: PM Iron vs Solid Forged Iron

Powder Metallurgy (PM) iron consists of finely powdered iron particles compacted and sintered, resulting in uniform microstructure with controlled porosity that improves machinability and wear resistance. Solid forged iron is produced by heating and hammering or pressing solid metal, yielding a denser and more homogenous grain structure with higher tensile strength and impact resistance. PM iron composition allows for precise alloying elements distribution, while solid forged iron typically exhibits fewer impurities but less flexibility in element integration.

Strength and Durability Comparison

Powder metallurgy iron exhibits superior uniformity and greater tensile strength compared to solid forged iron due to its fine microstructure and controlled porosity. Solid forged iron, while often denser, can have variable grain structures leading to inconsistent durability under cyclic stresses. The homogeneity in powder metallurgy iron enhances fatigue resistance, making it more durable for high-performance applications.

Precision and Dimensional Stability

Powder metallurgy iron exhibits superior precision and dimensional stability compared to solid forged iron due to its uniform microstructure and controlled porosity. This manufacturing method minimizes internal stresses and material distortions, ensuring tighter tolerances and consistent dimensions. In contrast, solid forged iron often experiences variable grain flow and residual stresses, leading to less predictable dimensional accuracy.

Manufacturing Efficiency and Scalability

Powder metallurgy iron offers superior manufacturing efficiency through near-net shape production, minimizing material waste and reducing machining requirements compared to solid forged iron. Its scalability is enhanced by the ability to produce complex geometries in high volumes with consistent quality, while solid forged iron typically involves longer cycle times and higher labor costs due to extensive machining and finishing processes. Industries prioritize powder metallurgy iron for applications requiring large-scale production and economical material utilization.

Application Versatility in Industries

Powder metallurgy iron exhibits superior application versatility in industries such as automotive, aerospace, and machinery due to its ability to produce complex shapes with tight tolerances and reduced material waste. Solid forged iron, while offering excellent structural strength and durability, is generally limited to simpler geometries and higher machining costs. This makes powder metallurgy iron particularly advantageous for mass production of intricate components, enhancing efficiency and performance in diverse industrial applications.

Cost Analysis: Production and Lifecycle

Powder metallurgy iron offers lower production costs due to reduced material waste and shorter machining times compared to solid forged iron, which requires extensive forging and machining processes. Lifecycle costs favor powder metallurgy iron as its near-net shape manufacturing results in consistent properties and minimal post-processing, whereas solid forged iron often demands additional treatments and maintenance. Cost efficiency in powder metallurgy also stems from improved material utilization and energy savings, leading to a more sustainable production cycle over the product's lifespan.

Environmental Impact and Sustainability

Powder metallurgy iron generates less waste and consumes significantly less energy compared to solid forged iron, reducing its carbon footprint. The precise shaping process in powder metallurgy minimizes material loss and supports efficient recycling, enhancing sustainability. In contrast, solid forged iron involves higher raw material consumption and energy-intensive heating cycles, leading to a greater environmental impact.

Powder Metallurgy Iron vs Solid Forged Iron Infographic

materialdif.com

materialdif.com