Microcrystalline graphite features fine, densely packed crystals, making it ideal for applications requiring high hardness and thermal resistance, such as in lubricants and battery anodes. Macrocrystalline graphite consists of larger, well-defined crystal structures that provide excellent electrical conductivity and are commonly used in electrodes and refractory materials. Understanding the distinctions between microcrystalline and macrocrystalline graphite allows for optimized selection based on performance requirements in industrial and technological applications.

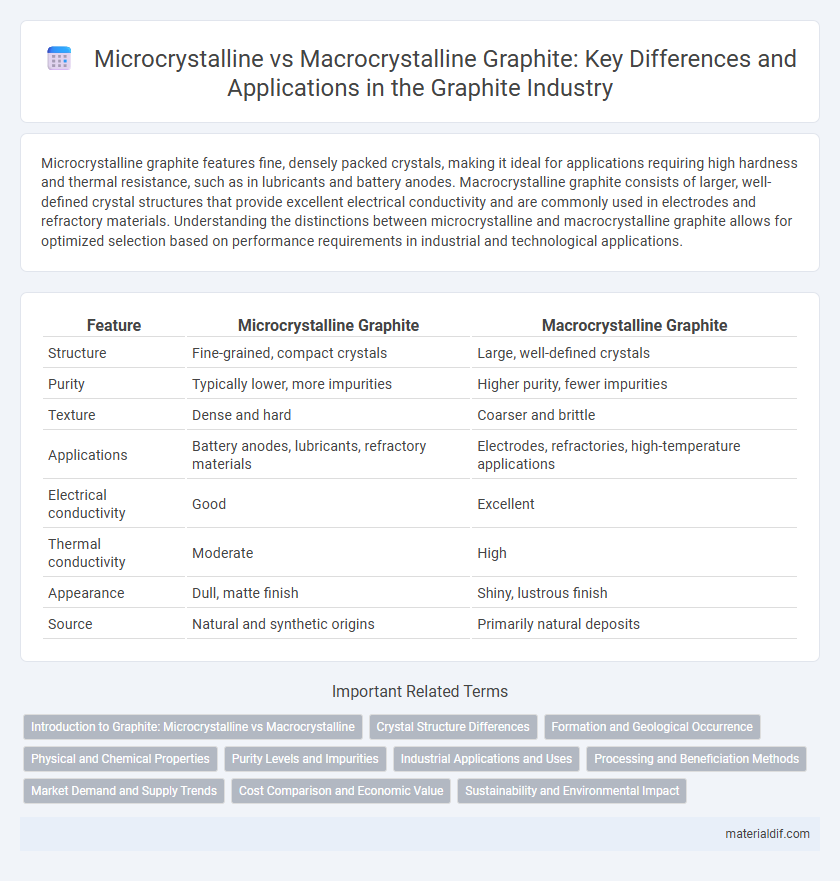

Table of Comparison

| Feature | Microcrystalline Graphite | Macrocrystalline Graphite |

|---|---|---|

| Structure | Fine-grained, compact crystals | Large, well-defined crystals |

| Purity | Typically lower, more impurities | Higher purity, fewer impurities |

| Texture | Dense and hard | Coarser and brittle |

| Applications | Battery anodes, lubricants, refractory materials | Electrodes, refractories, high-temperature applications |

| Electrical conductivity | Good | Excellent |

| Thermal conductivity | Moderate | High |

| Appearance | Dull, matte finish | Shiny, lustrous finish |

| Source | Natural and synthetic origins | Primarily natural deposits |

Introduction to Graphite: Microcrystalline vs Macrocrystalline

Microcrystalline graphite consists of fine, tightly packed crystallites typically less than a micron in size, offering high surface area and electrical conductivity ideal for battery anodes and lubricants. Macrocrystalline graphite features larger, well-defined crystals that provide superior structural integrity and thermal conductivity, making it suitable for refractory materials and high-temperature applications. Understanding these differences highlights the distinct industrial uses driven by crystallite size and morphology.

Crystal Structure Differences

Microcrystalline graphite consists of extremely small, randomly oriented carbon crystals typically less than 1 micron in size, resulting in a fine-grained, isotropic structure that enhances thermal shock resistance and mechanical strength. In contrast, macrocrystalline graphite features much larger, well-aligned graphite crystals ranging from several microns to millimeters, exhibiting anisotropic properties with higher electrical and thermal conductivity along the crystal planes. These crystal structure differences fundamentally influence their performance in applications such as electrodes, lubricants, and refractory materials.

Formation and Geological Occurrence

Microcrystalline graphite forms through the metamorphism of organic-rich sedimentary rocks under low to moderate temperatures, resulting in fine-grained, interlocking crystal structures commonly found in regional metamorphic environments. Macrocrystalline graphite develops under higher temperatures and pressures, often in contact metamorphic zones or hydrothermal veins, producing larger, more distinct crystals typically associated with igneous intrusions and high-grade metamorphic rocks. Geological occurrences of microcrystalline graphite are prevalent in areas with extensive sedimentary basins subjected to regional metamorphism, whereas macrocrystalline graphite is predominantly located near granitic intrusions and in areas of localized thermal alteration.

Physical and Chemical Properties

Microcrystalline graphite exhibits a fine, granular texture with smaller crystallite sizes typically below 1 micron, resulting in higher hardness and more isotropic mechanical properties compared to macrocrystalline graphite, which has larger, visible crystals providing greater electrical conductivity and thermal stability. Chemically, microcrystalline graphite is more reactive due to its increased surface area and defect density, influencing oxidation resistance and intercalation behavior, whereas macrocrystalline graphite's ordered lattice structure imparts enhanced chemical inertness. These differences impact applications where strength and wear resistance are prioritized for microcrystalline graphite, while superior conductivity and thermal performance favor macrocrystalline graphite usage.

Purity Levels and Impurities

Microcrystalline graphite exhibits higher purity levels with fewer impurities such as ash and metallic contaminants compared to macrocrystalline graphite, which often contains more structural imperfections and elemental impurities. The fine-grained structure of microcrystalline graphite allows for better control over impurity content, making it ideal for high-performance applications. Macrocrystalline graphite, characterized by larger crystal sizes, typically demonstrates lower purity and a higher concentration of sulfur, phosphorus, and other trace elements.

Industrial Applications and Uses

Microcrystalline graphite, characterized by its fine-grained structure and high purity, is widely used in lubricants, batteries, and conductive coatings due to its excellent thermal stability and electrical conductivity. Macrocrystalline graphite, featuring larger crystal sizes and higher density, is preferred in the production of electrodes, refractories, and nuclear reactors where mechanical strength and thermal resistance are critical. Industrial applications leverage microcrystalline graphite for precision engineering and chemical stability, while macrocrystalline graphite supports heavy-duty manufacturing and energy storage technologies.

Processing and Beneficiation Methods

Microcrystalline graphite undergoes fine grinding and flotation due to its small, tightly packed crystal structure, enabling efficient separation of impurities. Macrocrystalline graphite benefits from coarse crushing and gravity separation techniques, exploiting its larger, flake-like crystals for easier beneficiation. Chemical purification methods, such as acid leaching and thermal treatment, are commonly applied to both types to enhance carbon content and purity after physical processing.

Market Demand and Supply Trends

Microcrystalline graphite, characterized by smaller, fine-grained particles, experiences rising market demand due to its superior lubricity and high thermal conductivity, making it essential in electronics and battery applications. In contrast, macrocrystalline graphite, with larger flake sizes, dominates traditional markets such as metallurgy and refractories, benefiting from steady supply chains and established mining operations. Recent supply trends highlight a shift towards increased production of microcrystalline varieties to meet growing needs in high-tech industries, while macrocrystalline graphite maintains stable output supported by mature extraction techniques.

Cost Comparison and Economic Value

Microcrystalline graphite generally incurs lower production costs due to its finer grain structure and ease of extraction compared to macrocrystalline graphite. Macrocrystalline graphite, while costlier, offers superior purity and larger crystal size that enhances conductivity and mechanical strength, providing greater economic value in high-performance applications. The cost-benefit analysis often favors microcrystalline graphite for bulk industrial uses, whereas macrocrystalline graphite commands premium pricing justified by its specialized technological advantages.

Sustainability and Environmental Impact

Microcrystalline graphite, characterized by its fine, tightly packed crystals, typically has a lower environmental footprint due to its efficient production from natural or synthetic sources that require less energy and generate fewer emissions. Macrocrystalline graphite, with larger crystal structures, often involves more intensive mining processes that can result in greater habitat disruption and higher carbon emissions. Sustainable practices in microcrystalline graphite extraction and processing contribute to reduced land degradation and lower ecological impact compared to traditional macrocrystalline graphite mining.

Microcrystalline Graphite vs Macrocrystalline Graphite Infographic

materialdif.com

materialdif.com