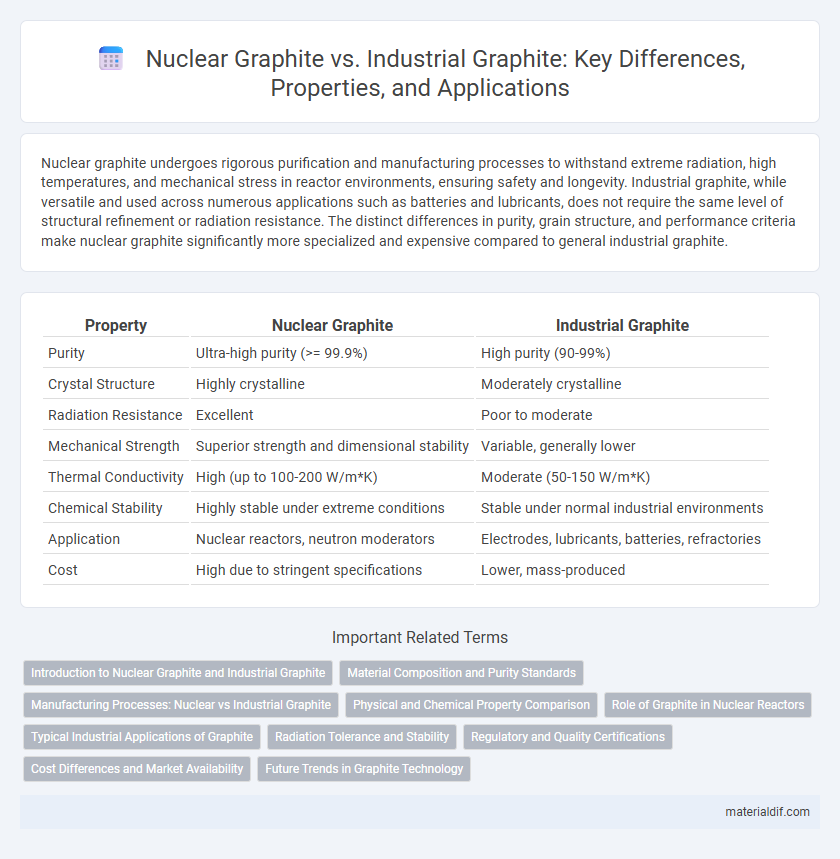

Nuclear graphite undergoes rigorous purification and manufacturing processes to withstand extreme radiation, high temperatures, and mechanical stress in reactor environments, ensuring safety and longevity. Industrial graphite, while versatile and used across numerous applications such as batteries and lubricants, does not require the same level of structural refinement or radiation resistance. The distinct differences in purity, grain structure, and performance criteria make nuclear graphite significantly more specialized and expensive compared to general industrial graphite.

Table of Comparison

| Property | Nuclear Graphite | Industrial Graphite |

|---|---|---|

| Purity | Ultra-high purity (>= 99.9%) | High purity (90-99%) |

| Crystal Structure | Highly crystalline | Moderately crystalline |

| Radiation Resistance | Excellent | Poor to moderate |

| Mechanical Strength | Superior strength and dimensional stability | Variable, generally lower |

| Thermal Conductivity | High (up to 100-200 W/m*K) | Moderate (50-150 W/m*K) |

| Chemical Stability | Highly stable under extreme conditions | Stable under normal industrial environments |

| Application | Nuclear reactors, neutron moderators | Electrodes, lubricants, batteries, refractories |

| Cost | High due to stringent specifications | Lower, mass-produced |

Introduction to Nuclear Graphite and Industrial Graphite

Nuclear graphite is a highly pure, specially engineered form of graphite used as a neutron moderator and structural material in nuclear reactors, designed to withstand extreme radiation and high temperatures. Industrial graphite, in contrast, encompasses various grades of graphite used in manufacturing processes such as electrodes, lubricants, and refractories without the stringent purity and performance requirements of nuclear applications. Key differences between nuclear and industrial graphite lie in their physical properties, purity levels, and application-specific performance criteria.

Material Composition and Purity Standards

Nuclear graphite is engineered with ultra-high purity levels, typically exceeding 99.9% carbon content, to minimize neutron absorption and prevent radioactive contamination in reactor environments. Industrial graphite, while still predominantly carbon, often contains higher levels of impurities such as sulfur, ash, and metallic elements, which can affect conductivity and mechanical strength but are acceptable for applications like electrodes and lubricants. The stringent purity standards for nuclear graphite ensure consistent isotopic composition and low porosity, critical for maintaining structural integrity and thermal performance under extreme radiation and temperature conditions.

Manufacturing Processes: Nuclear vs Industrial Graphite

Nuclear graphite undergoes specialized manufacturing involving precise control of impurities, high-density molding, and heat treatment to achieve exceptional neutron moderation and radiation resistance. Industrial graphite typically employs less stringent purification and lower temperature baking processes, optimized for electrical conductivity and mechanical strength in applications like electrodes and lubricants. The production of nuclear graphite demands strict quality assurance and monitoring to meet the rigorous standards required for use in nuclear reactors.

Physical and Chemical Property Comparison

Nuclear graphite exhibits exceptional purity with low impurity levels, high neutron moderation capacity, and superior radiation resistance, distinguishing it from industrial graphite. Industrial graphite typically contains higher impurities and demonstrates greater variability in density, porosity, and thermal conductivity, tailored for applications like electrodes and lubricants. The physical structure of nuclear graphite is highly crystalline with a controlled pore size distribution, while industrial graphite often has a heterogeneous microstructure affecting its mechanical strength and chemical stability.

Role of Graphite in Nuclear Reactors

Nuclear graphite, a high-purity form of graphite, plays a critical role as a neutron moderator and structural component in nuclear reactors, enabling efficient nuclear fission by slowing down neutrons. Unlike industrial graphite, which is primarily used for manufacturing electrodes, lubricants, and refractory materials, nuclear graphite must meet stringent standards for radiation resistance, thermal conductivity, and dimensional stability under high-temperature conditions. The exceptional performance of nuclear graphite ensures reactor safety and longevity, distinguishing it from the broader applications and quality requirements of industrial graphite.

Typical Industrial Applications of Graphite

Nuclear graphite is primarily used in high-temperature reactors and neutron moderators due to its exceptional purity and radiation resistance, enabling safe and efficient nuclear fission processes. Industrial graphite, with lower purity but high thermal and electrical conductivity, is widely applied in battery anodes, lubricants, refractory materials, and electrodes for electric arc furnaces. The differentiation in application stems from the specific performance requirements related to structural integrity, thermal stability, and chemical inertness in respective industrial environments.

Radiation Tolerance and Stability

Nuclear graphite exhibits superior radiation tolerance and dimensional stability under intense neutron irradiation compared to industrial graphite, making it essential for nuclear reactor cores. Its microstructure is engineered to minimize radiation-induced swelling and maintain thermal conductivity, ensuring reliable performance in high-radiation environments. Industrial graphite, while suitable for general applications, lacks the enhanced radiation resistance and mechanical stability required for nuclear-grade demands.

Regulatory and Quality Certifications

Nuclear graphite is subject to stringent regulatory standards such as ASTM C781 and NSC-M-4 guidelines to ensure radiation resistance and structural integrity in reactor environments, whereas industrial graphite primarily complies with ISO 9001 for manufacturing quality. Quality certifications for nuclear graphite include rigorous testing protocols for purity, density, and neutron absorption, surpassing those required for industrial-grade materials used in applications like electrodes or lubricants. Compliance with nuclear regulatory bodies such as the U.S. Nuclear Regulatory Commission (NRC) and the International Atomic Energy Agency (IAEA) further distinguishes nuclear graphite from industrial graphite, which is governed by broader industrial safety and quality standards.

Cost Differences and Market Availability

Nuclear graphite commands higher prices due to stringent purity and structural integrity requirements critical for reactor safety, whereas industrial graphite is produced with less rigorous specifications, resulting in lower costs. Market availability of nuclear graphite is limited owing to specialized manufacturing processes and regulatory approvals, contrasting with the broader and more accessible supply of industrial graphite used across diverse sectors. These cost and availability disparities influence the selection of graphite types, balancing budget constraints against performance criteria in applications.

Future Trends in Graphite Technology

Nuclear graphite is engineered with ultra-high purity and exceptional radiation resistance, making it essential for advanced reactor designs and next-generation nuclear technologies. Industrial graphite, while versatile and widely used in manufacturing, energy storage, and electronics, is seeing innovation focused on cost reduction and enhanced conductivity. Future trends highlight the development of synthetic graphite materials with tailored microstructures to meet the stringent performance requirements of nuclear applications while expanding the capabilities of industrial graphite in emerging energy storage systems.

Nuclear Graphite vs Industrial Graphite Infographic

materialdif.com

materialdif.com