Coarse graphite has larger particle sizes, offering superior lubricity and higher thermal conductivity, making it ideal for heavy-duty industrial applications. Fine graphite features smaller particles that enhance surface finish and provide better dispersion in composite materials, suitable for precision engineering. Choosing between coarse and fine graphite depends on the specific requirements for texture, conductivity, and application performance.

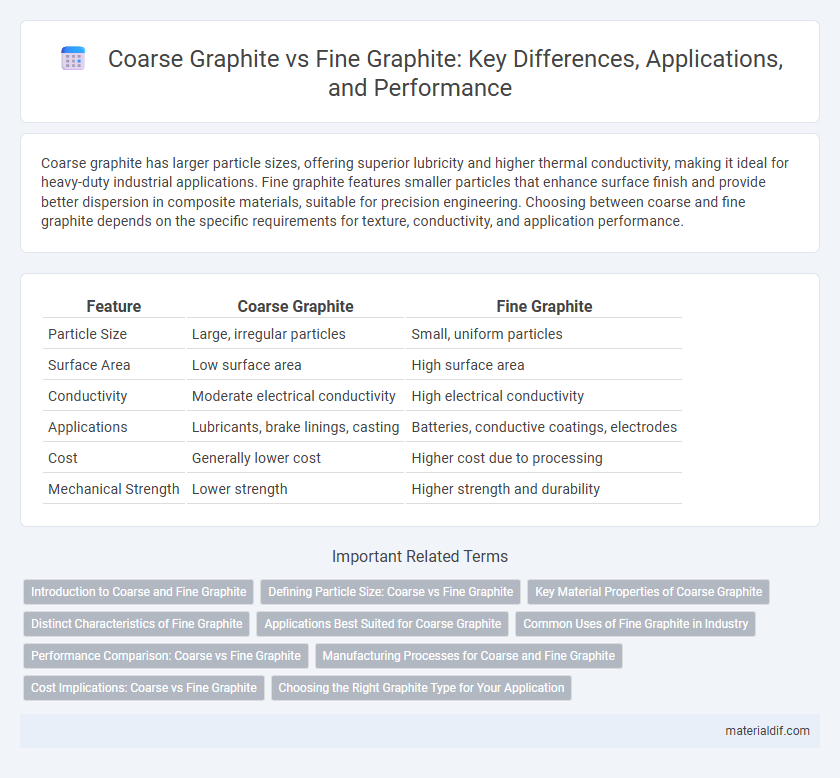

Table of Comparison

| Feature | Coarse Graphite | Fine Graphite |

|---|---|---|

| Particle Size | Large, irregular particles | Small, uniform particles |

| Surface Area | Low surface area | High surface area |

| Conductivity | Moderate electrical conductivity | High electrical conductivity |

| Applications | Lubricants, brake linings, casting | Batteries, conductive coatings, electrodes |

| Cost | Generally lower cost | Higher cost due to processing |

| Mechanical Strength | Lower strength | Higher strength and durability |

Introduction to Coarse and Fine Graphite

Coarse graphite features larger, more defined flake sizes typically ranging from 150 to 300 microns, offering enhanced electrical conductivity and thermal resistance in industrial applications. Fine graphite, with flake sizes below 150 microns, provides superior surface finish and increased reactivity, making it ideal for high-precision components and advanced battery technologies. Understanding the distinct properties and particle size distribution of coarse versus fine graphite is crucial for selecting the appropriate material for metallurgical, refractory, and lubricant applications.

Defining Particle Size: Coarse vs Fine Graphite

Coarse graphite typically features particle sizes larger than 150 microns, characterized by its lower surface area and higher structural integrity, making it ideal for applications requiring high thermal conductivity and wear resistance. Fine graphite, with particle sizes generally below 150 microns, offers increased surface area and reactivity, enhancing performance in battery anodes and lubrication where improved dispersion is critical. Understanding the distinctions in particle size directly influences the selection of graphite type for specific industrial processes, optimizing efficiency and material properties.

Key Material Properties of Coarse Graphite

Coarse graphite exhibits larger particle size and higher purity compared to fine graphite, resulting in enhanced thermal conductivity and improved electrical conductivity. Its greater porosity and structural integrity provide superior lubricating properties and wear resistance, making it ideal for high-temperature industrial applications. The mechanical strength and reduced reactivity of coarse graphite enable better performance in refractory materials and battery anodes.

Distinct Characteristics of Fine Graphite

Fine graphite is characterized by its small particle size, typically less than 50 microns, which enhances its surface area and reactivity compared to coarse graphite. Its higher purity and uniform particle distribution contribute to superior conductivity and lubrication properties, making it ideal for applications in batteries, lubricants, and refractories. Unlike coarse graphite, fine graphite exhibits improved suspension stability in fluids, facilitating better performance in coatings and conductive composites.

Applications Best Suited for Coarse Graphite

Coarse graphite, characterized by larger particle sizes and higher purity levels, is best suited for applications requiring excellent conductivity and thermal management, such as in refractory products, battery anodes, and brake linings. Its robust physical structure makes it ideal for use in foundry facings, lubricants, and corrosion-resistant materials where durability and heat resistance are critical. Industries relying on high-performance graphite with enhanced mechanical strength prefer coarse graphite for its superior performance in demanding environments.

Common Uses of Fine Graphite in Industry

Fine graphite is widely used in the electronics industry for manufacturing anodes in lithium-ion batteries due to its high purity and excellent conductivity. It is also essential in lubricants and coatings for aerospace and automotive components, providing superior thermal stability and wear resistance. Additionally, fine graphite is crucial in the production of refractories and crucibles where precise particle size ensures improved mechanical strength and chemical inertness.

Performance Comparison: Coarse vs Fine Graphite

Coarse graphite offers superior thermal conductivity and electrical performance due to larger crystalline structures facilitating electron flow. Fine graphite provides enhanced mechanical strength and surface area, improving wear resistance and reactivity in applications requiring precise material interactions. Performance selection depends on balancing conductivity needs with structural durability for optimal results in industrial and technological uses.

Manufacturing Processes for Coarse and Fine Graphite

Coarse graphite typically undergoes mechanical milling and crushing processes to achieve larger particle sizes ideal for applications requiring high thermal conductivity and electrical performance. Fine graphite is produced through advanced grinding techniques and air classification, enabling the creation of ultra-fine particles for precision uses such as lubricants and battery anodes. The controlled manufacturing processes for both coarse and fine graphite ensure optimal particle size distribution tailored to specific industrial requirements.

Cost Implications: Coarse vs Fine Graphite

Coarse graphite typically incurs lower costs due to its less intensive processing requirements and abundance in natural deposits. Fine graphite demands higher processing precision and purification, driving up production expenses and overall market price. Cost efficiency considerations often influence industrial applications, with coarse graphite preferred for bulk uses and fine graphite reserved for high-performance products.

Choosing the Right Graphite Type for Your Application

Coarse graphite features larger particle sizes that enhance thermal conductivity and electrical performance, making it ideal for applications like batteries and electrodes requiring efficient heat and current transfer. Fine graphite, with smaller particle sizes, offers superior lubricity and surface finish, suitable for precision parts, coatings, and high-strength composites where smooth texture and uniform dispersion are critical. Selecting the appropriate graphite type depends on specific performance needs such as thermal management, electrical conductivity, or mechanical properties to optimize application outcomes.

Coarse Graphite vs Fine Graphite Infographic

materialdif.com

materialdif.com