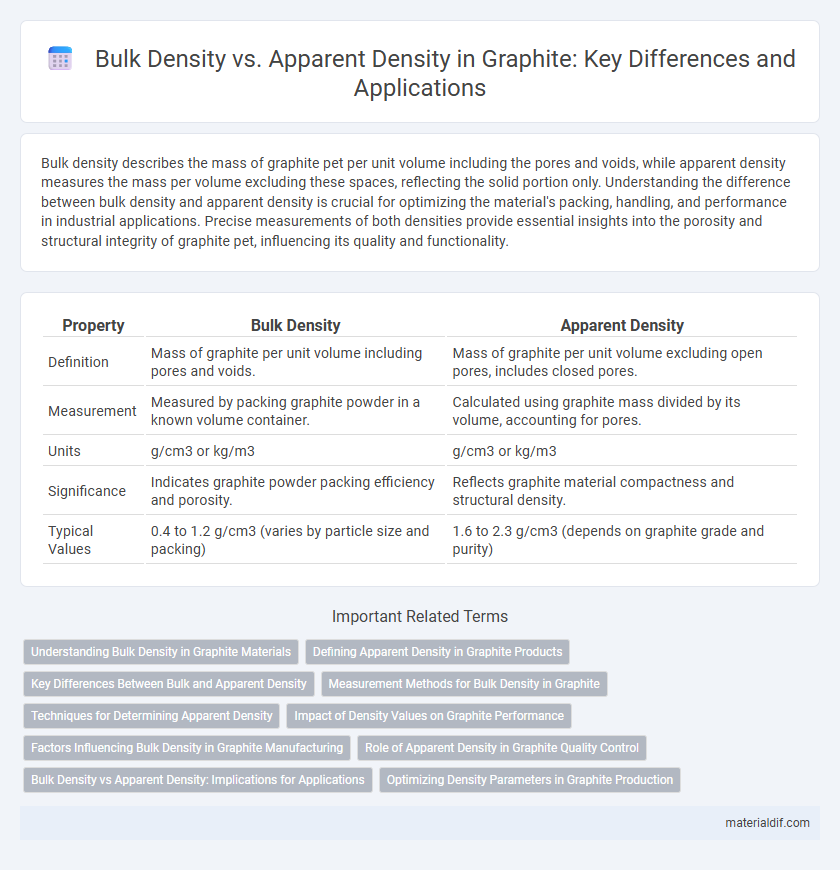

Bulk density describes the mass of graphite pet per unit volume including the pores and voids, while apparent density measures the mass per volume excluding these spaces, reflecting the solid portion only. Understanding the difference between bulk density and apparent density is crucial for optimizing the material's packing, handling, and performance in industrial applications. Precise measurements of both densities provide essential insights into the porosity and structural integrity of graphite pet, influencing its quality and functionality.

Table of Comparison

| Property | Bulk Density | Apparent Density |

|---|---|---|

| Definition | Mass of graphite per unit volume including pores and voids. | Mass of graphite per unit volume excluding open pores, includes closed pores. |

| Measurement | Measured by packing graphite powder in a known volume container. | Calculated using graphite mass divided by its volume, accounting for pores. |

| Units | g/cm3 or kg/m3 | g/cm3 or kg/m3 |

| Significance | Indicates graphite powder packing efficiency and porosity. | Reflects graphite material compactness and structural density. |

| Typical Values | 0.4 to 1.2 g/cm3 (varies by particle size and packing) | 1.6 to 2.3 g/cm3 (depends on graphite grade and purity) |

Understanding Bulk Density in Graphite Materials

Bulk density in graphite materials refers to the mass of graphite particles per unit volume, including the void spaces between particles, which directly impacts packing efficiency and material handling properties. Unlike apparent density, which measures the density of the graphite itself excluding pores and voids, bulk density provides critical insights into the porosity and particle arrangement affecting thermal conductivity and electrical performance. Accurate measurement of bulk density is essential for optimizing processes such as electrode manufacturing, refractory formulation, and composite material design.

Defining Apparent Density in Graphite Products

Apparent density in graphite products refers to the mass of graphite per unit volume, including the volume of open pores and void spaces within the material. This measurement is crucial for evaluating the overall compactness and quality of graphite blocks, especially in applications like electrodes and refractories. Unlike bulk density, apparent density accounts for all accessible pore volumes, influencing properties such as strength, thermal conductivity, and electrical performance.

Key Differences Between Bulk and Apparent Density

Bulk density of graphite measures the mass of the material per unit volume, including the air spaces between particles, while apparent density refers to the density of the solid particles themselves, excluding voids. Bulk density is typically lower due to the presence of pores and interstitial air, which affects packing and flow properties crucial for industrial applications. Apparent density provides insights into the purity and particle structure of graphite, important for quality control and material performance.

Measurement Methods for Bulk Density in Graphite

Measurement methods for bulk density in graphite typically involve the use of standardized techniques such as the ASTM D3170 or ISO 787-10 protocols, which measure the mass of graphite particles in a known volume without void spaces between particles. Techniques like tamped bulk density and poured bulk density assess how graphite powder settles under different compaction conditions, providing critical data for material handling and quality control. Accurate measurement of bulk density influences the performance characteristics of graphite in applications such as electrodes, batteries, and refractory materials.

Techniques for Determining Apparent Density

Apparent density of graphite is commonly determined using techniques such as mercury intrusion porosimetry, helium pycnometry, and gas displacement methods, which accurately measure the volume excluding open pores. These methods differ from bulk density measurements that consider the total volume, including pore spaces and voids, influencing material performance in applications like electrodes and refractory components. Precise apparent density data helps optimize manufacturing processes and enhance graphite's structural and thermal properties.

Impact of Density Values on Graphite Performance

Bulk density and apparent density significantly influence graphite's thermal conductivity and mechanical strength, impacting its suitability for high-performance applications such as electrodes and battery anodes. Higher bulk density typically correlates with improved electrical conductivity and stability, while apparent density affects porosity and material durability under thermal stress. Optimizing these density parameters enhances graphite's efficiency in energy storage, aerospace, and refractory industries.

Factors Influencing Bulk Density in Graphite Manufacturing

Bulk density in graphite manufacturing is influenced by particle size distribution, moisture content, and compaction pressure during the molding process. Finer graphite particles and higher compaction pressures increase bulk density by reducing void spaces between particles. Variations in moisture content can alter particle cohesion, significantly affecting the packing efficiency and resulting bulk density.

Role of Apparent Density in Graphite Quality Control

Apparent density in graphite measures the mass of graphite particles relative to the total volume they occupy, including the pore spaces, which directly affects the material's performance in industrial applications. This parameter is crucial for quality control as it helps determine the packing efficiency and consistency of graphite powders used in electrodes, batteries, and refractory products. Monitoring apparent density ensures uniformity in product specifications, optimizing electrical conductivity and mechanical strength in final graphite components.

Bulk Density vs Apparent Density: Implications for Applications

Bulk density, defined as the mass of graphite per unit volume including pore spaces, directly influences material handling, packaging, and transport efficiency in industrial applications. Apparent density, which excludes closed pores and considers only the solid material and open pores, is critical for evaluating graphite's performance in high-precision areas like battery anodes and conductive materials. Understanding the distinction between bulk density and apparent density ensures optimized application design by predicting mechanical strength, electrical conductivity, and thermal stability in composite systems.

Optimizing Density Parameters in Graphite Production

Optimizing density parameters in graphite production requires distinguishing bulk density, which includes pore spaces and voids, from apparent density that measures the solid material alone. Controlling factors such as particle size distribution, compaction pressure, and heat treatment conditions directly influences porosity and density uniformity in graphite products. Precise calibration of these parameters enhances mechanical strength, electrical conductivity, and overall performance of high-quality graphite materials.

Bulk Density vs Apparent Density Infographic

materialdif.com

materialdif.com