Graphite sheets offer flexibility and uniform heat distribution, making them ideal for applications requiring precise thermal management. Graphite rods provide superior structural integrity and are preferred in scenarios needing durability and electrical conductivity. Choosing between a graphite sheet and rod depends on the specific demands of heat dissipation, mechanical strength, and electrical performance within the pet's environment.

Table of Comparison

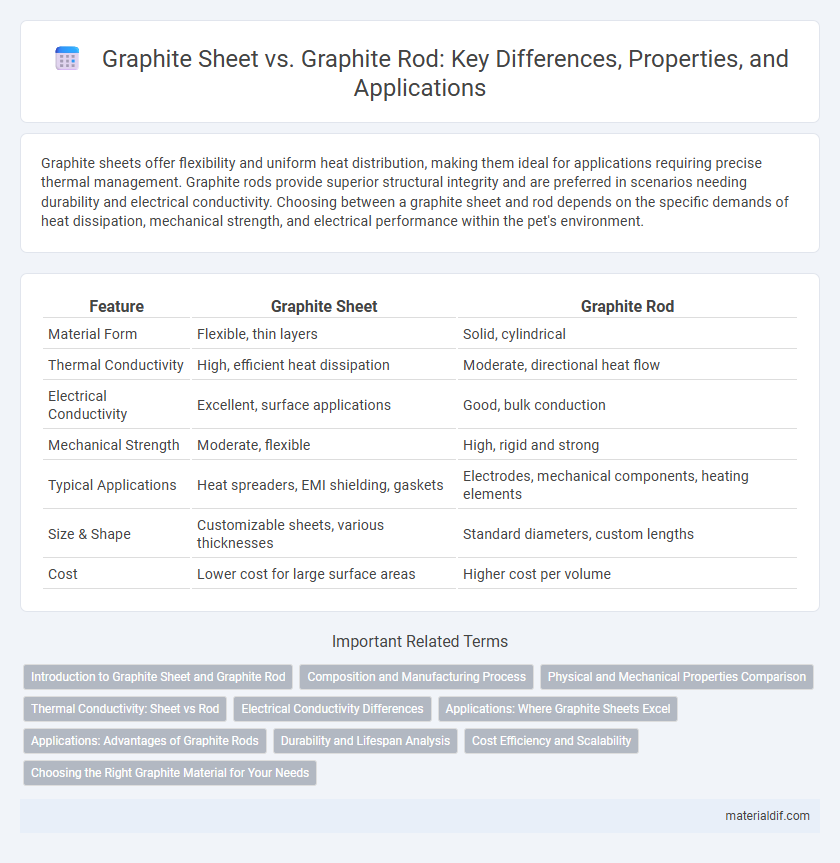

| Feature | Graphite Sheet | Graphite Rod |

|---|---|---|

| Material Form | Flexible, thin layers | Solid, cylindrical |

| Thermal Conductivity | High, efficient heat dissipation | Moderate, directional heat flow |

| Electrical Conductivity | Excellent, surface applications | Good, bulk conduction |

| Mechanical Strength | Moderate, flexible | High, rigid and strong |

| Typical Applications | Heat spreaders, EMI shielding, gaskets | Electrodes, mechanical components, heating elements |

| Size & Shape | Customizable sheets, various thicknesses | Standard diameters, custom lengths |

| Cost | Lower cost for large surface areas | Higher cost per volume |

Introduction to Graphite Sheet and Graphite Rod

Graphite sheets offer exceptional thermal conductivity and flexibility, making them ideal for heat dissipation in electronic devices and batteries. Graphite rods provide high strength and chemical resistance, commonly used as electrodes, in industrial applications, and as heat sources. Both forms leverage graphite's unique combination of electrical conductivity, lubrication properties, and thermal stability for specialized engineering solutions.

Composition and Manufacturing Process

Graphite sheets are composed of high-purity natural or synthetic graphite flakes compressed into thin, flexible layers, offering excellent thermal conductivity and flexibility. Graphite rods consist of dense, isotropic graphite formed by extruding or molding graphite powder mixed with binders, then baked at high temperatures to achieve rigidity and structural integrity. The manufacturing process of graphite sheets emphasizes lamination and calendering for uniform thickness, while rods undergo pressing and high-temperature graphitization for enhanced mechanical strength.

Physical and Mechanical Properties Comparison

Graphite sheets exhibit superior flexibility and thermal conductivity compared to graphite rods, making them ideal for applications requiring efficient heat dissipation in confined spaces. Graphite rods possess higher compressive strength and rigidity, enabling them to withstand mechanical stress and structural loads more effectively than sheets. The anisotropic nature of graphite results in sheets having enhanced in-plane electrical conductivity, while rods maintain uniform properties along their length, crucial for precision machining and structural components.

Thermal Conductivity: Sheet vs Rod

Graphite sheets exhibit higher thermal conductivity along the plane due to their layered structure, facilitating efficient heat dissipation across surfaces. In contrast, graphite rods demonstrate superior conductivity along their length, making them ideal for applications requiring heat transfer in a linear direction. Thermal conductivity values for graphite sheets can reach up to 150-400 W/m*K in-plane, while rods typically range around 100-200 W/m*K along their axis.

Electrical Conductivity Differences

Graphite sheets offer enhanced electrical conductivity due to their planar structure, which facilitates electron flow across two dimensions, making them ideal for applications requiring efficient current distribution and heat dissipation. In contrast, graphite rods provide conductivity primarily along their longitudinal axis, resulting in anisotropic electrical properties that limit their effectiveness in uniformly spreading electrical currents. The differing microstructures impact their suitability in electronics, with sheets favored for flexible circuits and rods used in electrodes or high-current applications where directional conductivity is advantageous.

Applications: Where Graphite Sheets Excel

Graphite sheets excel in applications requiring uniform heat distribution, such as in thermal management for electronics and battery packs, due to their high thermal conductivity and flexibility. Their thin, pliable form allows easy integration into layered assemblies, providing efficient thermal interface solutions used in smartphones, laptops, and LED lighting. In contrast, graphite rods are primarily suited for structural, high-temperature furnace components, and electrochemical electrodes, where rigidity and mechanical strength are essential.

Applications: Advantages of Graphite Rods

Graphite rods offer superior mechanical strength and electrical conductivity, making them ideal for use in electrolysis, arc welding, and battery electrodes. Their cylindrical shape allows for uniform current distribution and easy integration into cylindrical equipment, unlike graphite sheets which are more suited for shielding and thermal management. The durability and chemical stability of graphite rods enhance their performance in harsh industrial environments, providing longer service life and reduced maintenance costs.

Durability and Lifespan Analysis

Graphite sheets exhibit superior flexibility and resistance to thermal shock, making them highly durable for gasket and sealing applications, while graphite rods offer higher mechanical strength and wear resistance suited for structural components. The lifespan of graphite sheets is often extended in dynamic environments due to their conformity and compressibility, whereas graphite rods tend to have a longer operational life under static, load-bearing conditions because of their dense and crystalline composition. Selecting between graphite sheet and rod depends on the specific durability requirements and operational stresses, with sheets excelling in sealing roles and rods preferred for mechanical durability over time.

Cost Efficiency and Scalability

Graphite sheets provide cost efficiency through easier manufacturing and customization, making them ideal for scalable applications in thermal management and electrical conductivity. Graphite rods, while offering higher strength and stability, typically involve higher production costs and less flexibility in sizing, limiting scalability in some industrial uses. Choosing sheets over rods enables businesses to optimize expenses and adapt rapidly to changing project requirements.

Choosing the Right Graphite Material for Your Needs

Graphite sheets offer flexibility, excellent thermal conductivity, and are ideal for gasketing, insulation, and heat dissipation applications, while graphite rods provide superior mechanical strength and are better suited for electrodes, machining, and high-temperature environments. Selecting the right graphite material depends on your specific application requirements, such as flexibility versus rigidity, thermal performance, and mechanical durability. Understanding these properties ensures optimal performance and longevity in industrial, electrical, or thermal management uses.

Graphite Sheet vs Graphite Rod Infographic

materialdif.com

materialdif.com