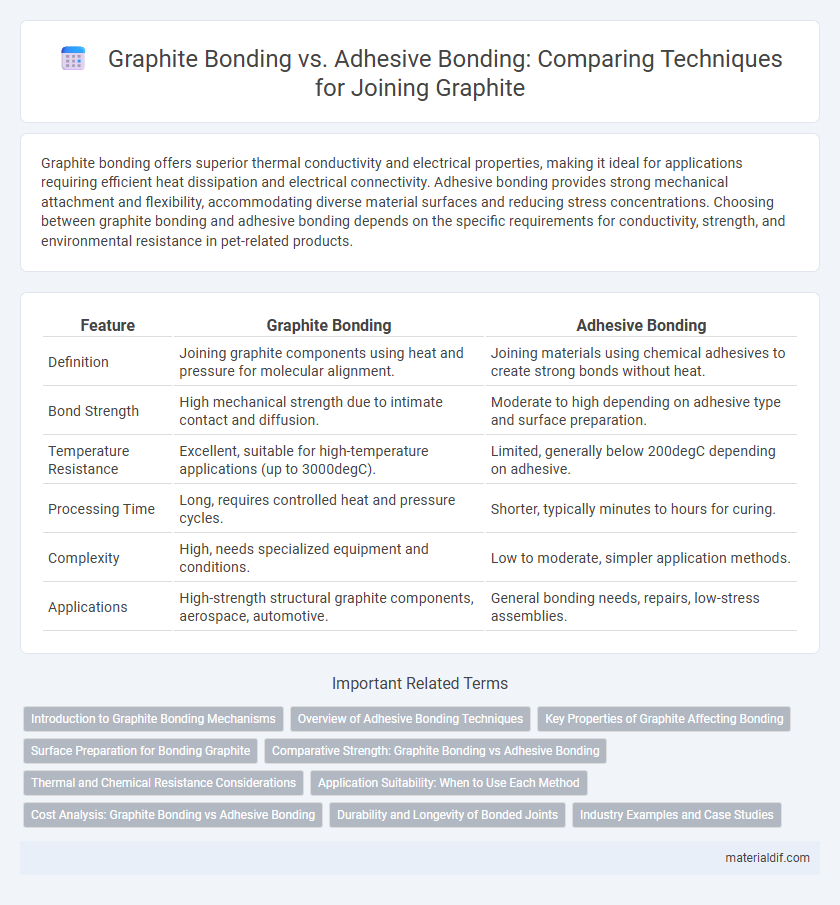

Graphite bonding offers superior thermal conductivity and electrical properties, making it ideal for applications requiring efficient heat dissipation and electrical connectivity. Adhesive bonding provides strong mechanical attachment and flexibility, accommodating diverse material surfaces and reducing stress concentrations. Choosing between graphite bonding and adhesive bonding depends on the specific requirements for conductivity, strength, and environmental resistance in pet-related products.

Table of Comparison

| Feature | Graphite Bonding | Adhesive Bonding |

|---|---|---|

| Definition | Joining graphite components using heat and pressure for molecular alignment. | Joining materials using chemical adhesives to create strong bonds without heat. |

| Bond Strength | High mechanical strength due to intimate contact and diffusion. | Moderate to high depending on adhesive type and surface preparation. |

| Temperature Resistance | Excellent, suitable for high-temperature applications (up to 3000degC). | Limited, generally below 200degC depending on adhesive. |

| Processing Time | Long, requires controlled heat and pressure cycles. | Shorter, typically minutes to hours for curing. |

| Complexity | High, needs specialized equipment and conditions. | Low to moderate, simpler application methods. |

| Applications | High-strength structural graphite components, aerospace, automotive. | General bonding needs, repairs, low-stress assemblies. |

Introduction to Graphite Bonding Mechanisms

Graphite bonding mechanisms primarily involve the interaction of carbon atoms through van der Waals forces and pi-pi stacking, providing strong yet reversible adhesion between layers. Adhesive bonding, in contrast, typically uses polymers or resins to create a chemical or mechanical linkage, which can be less effective for layered graphite structures. Understanding these differences is crucial for optimizing material performance in applications like battery electrodes and composite materials.

Overview of Adhesive Bonding Techniques

Adhesive bonding techniques involve the use of chemical substances to join graphite components, enhancing mechanical strength and electrical conductivity. Common methods include epoxy, polyurethane, and acrylic adhesives, each selected based on thermal stability, flexibility, and environmental resistance. These techniques offer uniform stress distribution and corrosion protection, making them suitable for high-performance graphite applications in aerospace and electronics.

Key Properties of Graphite Affecting Bonding

Graphite exhibits excellent thermal stability and electrical conductivity, which influence its bonding characteristics by requiring adhesives that can withstand high temperatures and maintain electrical pathways. Its layered crystal structure creates a naturally lubricious surface, challenging adhesion by reducing mechanical interlocking, thus necessitating surface treatments or specialized adhesives for effective bonding. The inherent chemical inertness and low surface energy of graphite further complicate adhesive bonding, demanding formulations with strong chemical affinity to ensure durable and reliable joint performance.

Surface Preparation for Bonding Graphite

Effective surface preparation for graphite bonding involves thorough cleaning and abrasion to remove contaminants and enhance surface roughness, promoting mechanical interlocking. In graphite adhesive bonding, surface treatments such as plasma etching or chemical priming improve adhesive wettability and chemical bonding strength. Proper preparation ensures optimal bond durability by maximizing surface energy and adhesion sites on the graphite substrate.

Comparative Strength: Graphite Bonding vs Adhesive Bonding

Graphite bonding provides superior thermal stability and mechanical strength compared to traditional adhesive bonding, making it ideal for high-stress applications. Adhesive bonding typically exhibits lower load-bearing capacity and reduced resistance to environmental factors such as temperature fluctuations and chemical exposure. The enhanced durability and stiffness of graphite bonds result from its atomic structure and covalent bonding, offering a significant advantage in aerospace and automotive industries.

Thermal and Chemical Resistance Considerations

Graphite bonding offers superior thermal resistance compared to adhesive bonding, maintaining stability at temperatures exceeding 3000degC, while most adhesives degrade above 200degC. Chemically, graphite bonds exhibit exceptional resistance to corrosive environments, including acids and alkalis, unlike conventional adhesives which may deteriorate or lose adhesion under aggressive chemical exposure. These properties make graphite bonding ideal for high-temperature and chemically harsh applications where adhesive bonding fails to provide long-term durability.

Application Suitability: When to Use Each Method

Graphite bonding is ideal for high-temperature applications and environments requiring excellent thermal conductivity, such as aerospace and electronics cooling systems. Adhesive bonding suits general-purpose uses with moderate mechanical stress and temperature ranges, often found in automotive and construction industries. Choosing between graphite and adhesive bonding depends on the specific operational demands, including thermal stability, electrical conductivity, and mechanical load.

Cost Analysis: Graphite Bonding vs Adhesive Bonding

Graphite bonding typically incurs higher initial costs due to the need for specialized equipment and materials, whereas adhesive bonding offers lower upfront expenses with simpler application processes. Over time, adhesive bonding may require more maintenance and potential rework, leading to increased lifecycle costs compared to the durable and stable nature of graphite bonding. Cost analysis must consider not only material and labor expenses but also long-term performance and reliability to determine the most economical bonding method.

Durability and Longevity of Bonded Joints

Graphite bonding demonstrates superior durability and longevity compared to traditional adhesive bonding due to its excellent thermal stability and chemical resistance, which prevent degradation under extreme conditions. The inherent strength of graphite-to-graphite bonds maintains structural integrity over extended periods, minimizing weaknesses caused by environmental exposure and mechanical stress. In contrast, adhesive bonds often degrade faster due to susceptibility to moisture, temperature fluctuations, and chemical attack, reducing their effective lifespan in demanding applications.

Industry Examples and Case Studies

Graphite bonding excels in high-temperature and chemically aggressive environments, demonstrated by its use in aerospace turbine blade manufacturing to ensure thermal stability and mechanical integrity. Adhesive bonding dominates in automotive assembly, enabling lightweight design and effective stress distribution in vehicle body panels, as seen in electric vehicle production lines. Case studies reveal that graphite bonding offers superior conductivity and durability in electronics cooling systems, while adhesive bonding provides versatile joining solutions in consumer electronics and structural composites.

Graphite Bonding vs Adhesive Bonding Infographic

materialdif.com

materialdif.com