Molded graphite offers superior durability and higher resistance to heat and chemicals compared to pressed graphite, making it ideal for demanding industrial applications. Pressed graphite, created by compressing graphite flakes with binders, provides greater flexibility and cost-effectiveness but may lack the same level of mechanical strength. Choosing between molded and pressed graphite depends on specific operational requirements such as pressure tolerance and environmental exposure.

Table of Comparison

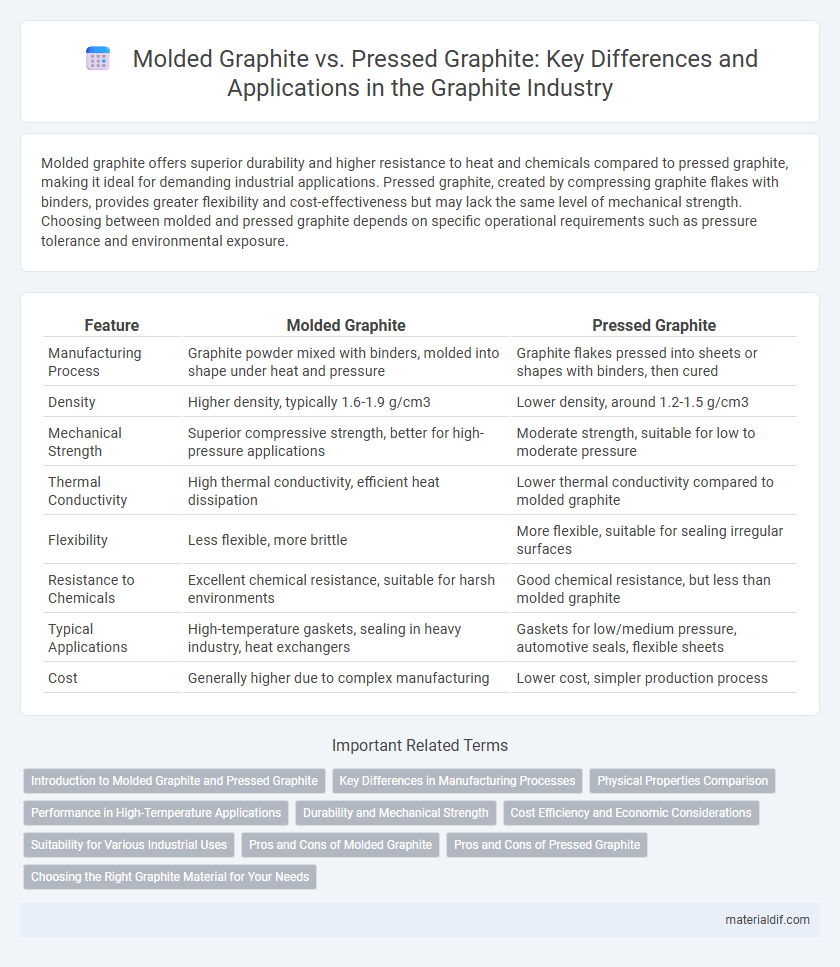

| Feature | Molded Graphite | Pressed Graphite |

|---|---|---|

| Manufacturing Process | Graphite powder mixed with binders, molded into shape under heat and pressure | Graphite flakes pressed into sheets or shapes with binders, then cured |

| Density | Higher density, typically 1.6-1.9 g/cm3 | Lower density, around 1.2-1.5 g/cm3 |

| Mechanical Strength | Superior compressive strength, better for high-pressure applications | Moderate strength, suitable for low to moderate pressure |

| Thermal Conductivity | High thermal conductivity, efficient heat dissipation | Lower thermal conductivity compared to molded graphite |

| Flexibility | Less flexible, more brittle | More flexible, suitable for sealing irregular surfaces |

| Resistance to Chemicals | Excellent chemical resistance, suitable for harsh environments | Good chemical resistance, but less than molded graphite |

| Typical Applications | High-temperature gaskets, sealing in heavy industry, heat exchangers | Gaskets for low/medium pressure, automotive seals, flexible sheets |

| Cost | Generally higher due to complex manufacturing | Lower cost, simpler production process |

Introduction to Molded Graphite and Pressed Graphite

Molded graphite is created by compressing natural graphite particles with binders under high pressure, resulting in dense and durable shapes ideal for high-temperature industrial applications. Pressed graphite, on the other hand, involves pressing graphite flakes into sheets or components, offering flexibility and lower density but with less mechanical strength compared to molded graphite. Both materials exhibit excellent thermal conductivity and chemical resistance, making them suitable for sealing, gasketing, and heat management in various engineering environments.

Key Differences in Manufacturing Processes

Molded graphite is produced by compacting graphite particles with a resin binder under high pressure and temperature, resulting in a denser and more uniform structure. Pressed graphite, on the other hand, is formed by pressing loose graphite flakes into shape without a binder, often leading to a more porous and less consistent material. These manufacturing differences impact the mechanical strength, thermal conductivity, and chemical resistance of the final graphite product.

Physical Properties Comparison

Molded graphite exhibits higher density and improved structural integrity compared to pressed graphite, leading to enhanced mechanical strength and reduced porosity. Pressed graphite, generally less dense, offers superior flexibility and compressibility, making it suitable for applications requiring effective sealing under varied pressure conditions. The thermal conductivity of molded graphite typically surpasses that of pressed graphite due to its more uniform microstructure and fewer voids.

Performance in High-Temperature Applications

Molded graphite exhibits superior structural integrity and thermal stability compared to pressed graphite, making it ideal for high-temperature applications exceeding 500degC. Its dense, uniform composition enhances resistance to thermal shock and chemical corrosion, ensuring consistent performance in demanding environments like furnace linings and heat exchangers. Pressed graphite, while cost-effective, generally shows lower mechanical strength and porosity control, limiting its effectiveness in extreme temperature conditions.

Durability and Mechanical Strength

Molded graphite exhibits higher mechanical strength and greater durability compared to pressed graphite due to its denser and more uniform structure achieved through isostatic pressing. Pressed graphite tends to have lower mechanical integrity and can be more prone to cracking under extreme conditions, limiting its lifespan in high-stress applications. The superior compressive strength and resilience of molded graphite make it ideal for demanding sealing and gasket applications in harsh environments.

Cost Efficiency and Economic Considerations

Molded graphite offers higher cost efficiency due to its superior durability and thermal stability, leading to longer service life and reduced replacement expenses in industrial applications. Pressed graphite, while initially less expensive, often incurs higher maintenance costs because of its lower mechanical strength and susceptibility to oxidation. Companies prioritizing total economic considerations typically favor molded graphite for long-term investments despite its higher upfront cost.

Suitability for Various Industrial Uses

Molded graphite exhibits exceptional density and mechanical strength, making it ideal for high-pressure sealing applications in petrochemical and power generation industries. Pressed graphite, characterized by its flexibility and lower density, suits dynamic environments such as automotive gaskets and heat exchangers where vibration resistance is critical. Selecting between molded and pressed graphite depends on specific industrial requirements including temperature tolerance, chemical exposure, and mechanical stress.

Pros and Cons of Molded Graphite

Molded graphite exhibits superior density and mechanical strength compared to pressed graphite, enhancing durability and allowing for higher-pressure applications. Its isotropic structure delivers consistent thermal conductivity and excellent chemical resistance, ideal for extreme environments. However, molded graphite is typically more expensive and less flexible than pressed graphite, limiting its use in cost-sensitive or complex-shape requirements.

Pros and Cons of Pressed Graphite

Pressed graphite offers superior mechanical strength and enhanced resistance to blowout under high pressure compared to molded graphite, making it ideal for demanding sealing applications. However, its lower compressibility can limit sealing flexibility and may lead to reduced performance in applications requiring tight conformity to flange irregularities. The production process of pressed graphite also tends to be less environmentally friendly due to the use of binders, which can affect chemical resistance and long-term durability.

Choosing the Right Graphite Material for Your Needs

Molded graphite offers superior density and structural integrity, making it ideal for high-pressure and high-temperature applications such as gasket manufacturing and thermal insulation. Pressed graphite provides excellent flexibility and cost-effectiveness, suited for less demanding environments where conformability and vibration resistance are crucial. Choosing the right graphite material depends on specific requirements like operating temperature, mechanical stress, and chemical exposure to ensure optimal performance and longevity.

Molded Graphite vs Pressed Graphite Infographic

materialdif.com

materialdif.com