Purified graphite offers higher purity levels essential for applications requiring excellent electrical conductivity and thermal stability, such as in batteries and lubricants. Unpurified graphite contains impurities like sulfur and ash, which can reduce performance and cause inefficiencies in industrial uses. Selecting purified graphite ensures enhanced quality, durability, and consistency in sensitive technological and manufacturing processes.

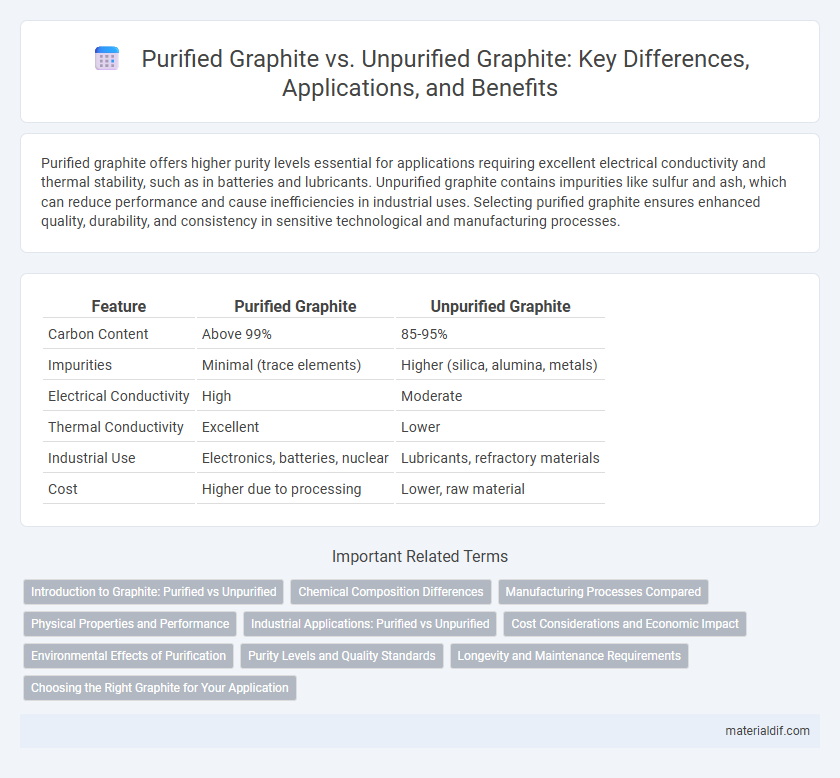

Table of Comparison

| Feature | Purified Graphite | Unpurified Graphite |

|---|---|---|

| Carbon Content | Above 99% | 85-95% |

| Impurities | Minimal (trace elements) | Higher (silica, alumina, metals) |

| Electrical Conductivity | High | Moderate |

| Thermal Conductivity | Excellent | Lower |

| Industrial Use | Electronics, batteries, nuclear | Lubricants, refractory materials |

| Cost | Higher due to processing | Lower, raw material |

Introduction to Graphite: Purified vs Unpurified

Purified graphite contains a higher carbon content, typically exceeding 99%, making it essential for high-performance applications such as batteries and lubricants. Unpurified graphite retains impurities like ash and other minerals, which can affect thermal conductivity and electrical performance. Selecting purified versus unpurified graphite depends on the required purity level for specific industrial uses and cost considerations.

Chemical Composition Differences

Purified graphite contains a higher concentration of carbon, typically exceeding 99%, with significantly reduced levels of impurities such as iron, sulfur, and ash compared to unpurified graphite. Unpurified graphite often contains considerable amounts of non-carbon elements and minerals, which can adversely affect its electrical conductivity and thermal stability. The chemical composition differences influence the suitability of purified graphite for high-performance applications in batteries, electrodes, and lubricants, whereas unpurified graphite is used in less demanding industrial processes.

Manufacturing Processes Compared

Purified graphite undergoes advanced manufacturing processes such as chemical purification, acid leaching, and high-temperature heat treatment to remove impurities like ash, metals, and volatile components, resulting in a higher carbon content above 99%. Unpurified graphite typically involves mechanical crushing and sieving with minimal processing, preserving inherent impurities and lower purity levels around 85-90%. The enhanced purification process improves electrical conductivity, thermal stability, and suitability for high-performance applications in industries like batteries, lubricants, and refractories.

Physical Properties and Performance

Purified graphite exhibits higher purity levels, resulting in enhanced thermal conductivity and electrical performance compared to unpurified graphite. Its improved mechanical strength and reduced impurity content make it more suitable for high-performance applications such as batteries, lubricants, and refractories. Unpurified graphite typically contains mineral impurities that diminish its physical properties, leading to lower durability and efficiency.

Industrial Applications: Purified vs Unpurified

Purified graphite exhibits higher conductivity and thermal stability, making it ideal for applications in lithium-ion batteries, fuel cells, and high-performance catalysts. Unpurified graphite, containing more impurities, is commonly used in refractories, brake linings, and lubricants where ultra-high purity is not critical. Industrial processes prioritize purified graphite for electronic components and advanced materials, while unpurified graphite suits bulk applications requiring lower cost and moderate performance.

Cost Considerations and Economic Impact

Purified graphite undergoes advanced refinement processes, significantly increasing production costs compared to unpurified graphite, which requires minimal processing. The higher purity level of purified graphite enhances its market value and applications in high-tech industries, such as batteries and electronics, driving greater economic returns. Unpurified graphite remains cost-effective for bulk applications like refractory materials, but its lower economic impact reflects limited versatility and demand in emerging technologies.

Environmental Effects of Purification

Purified graphite significantly reduces environmental pollution by minimizing the release of hazardous impurities such as sulfur, heavy metals, and other toxic elements commonly found in unpurified graphite. The purification process, often involving chemical leaching or thermal treatment, demands energy input and generates waste streams that require proper management to prevent soil and water contamination. Implementing advanced purification technologies and waste recycling methods can mitigate environmental impacts, promoting sustainable graphite production while meeting industrial-grade quality standards.

Purity Levels and Quality Standards

Purified graphite typically contains carbon content exceeding 99.9%, meeting stringent quality standards essential for high-performance applications such as lithium-ion batteries and aerospace components. Unpurified graphite, with carbon levels often below 95%, contains impurities like sulfur, ash, and other metallic elements that can compromise conductivity and structural integrity. Higher purity levels in purified graphite ensure enhanced electrical conductivity, thermal stability, and chemical resistance, making it the preferred choice for advanced industrial uses.

Longevity and Maintenance Requirements

Purified graphite exhibits significantly enhanced longevity due to its reduced impurities, which minimize oxidation and structural degradation over time compared to unpurified graphite. The maintenance requirements for purified graphite are lower, as it resists contamination and maintains performance without frequent cleaning or replacement. Unpurified graphite, prone to faster wear and impurity buildup, demands more regular inspections and maintenance to ensure operational efficiency.

Choosing the Right Graphite for Your Application

Purified graphite offers higher conductivity and fewer impurities, making it ideal for high-performance applications like batteries and electrodes. Unpurified graphite contains natural contaminants that may interfere with electrical or thermal efficiency but remain suitable for uses such as lubricants and refractories. Selecting the right graphite depends on balancing cost and purity requirements relative to the specific application's performance standards.

Purified Graphite vs Unpurified Graphite Infographic

materialdif.com

materialdif.com