Milled graphite offers finer particle sizes that provide better lubrication and improved surface finish compared to granular graphite, making it ideal for high-performance industrial applications. Granular graphite, characterized by its coarser texture, is commonly used in refractory materials and as a structural additive due to its superior thermal stability. Selecting between milled and granular graphite depends on the specific wear resistance, thermal conductivity, and application requirements in graphite pet products.

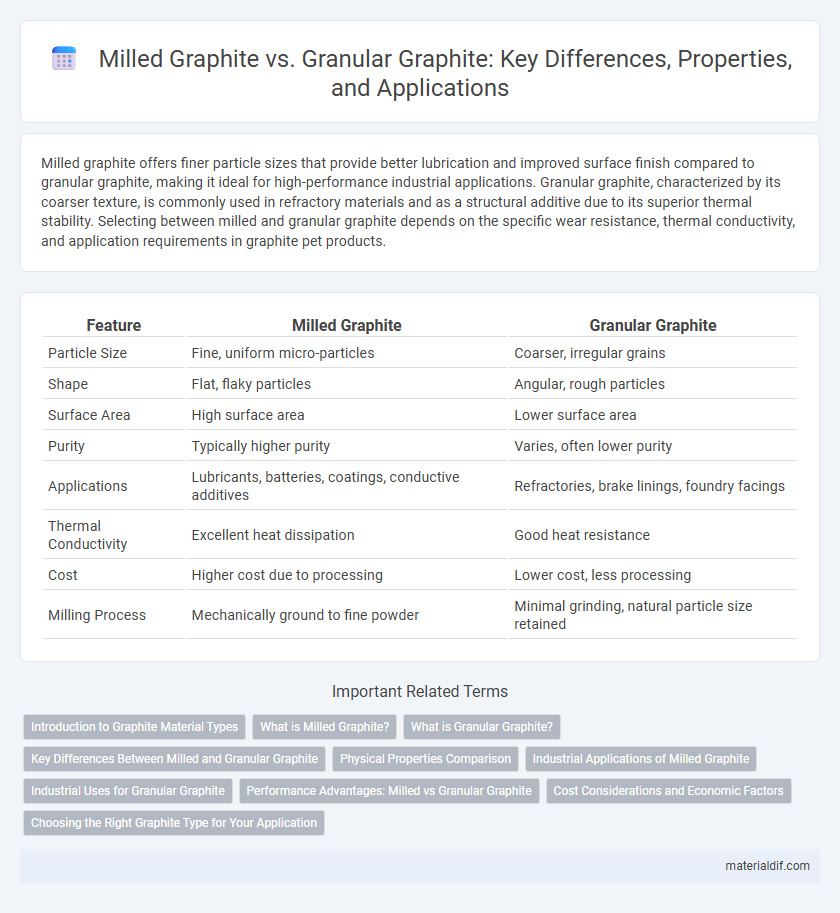

Table of Comparison

| Feature | Milled Graphite | Granular Graphite |

|---|---|---|

| Particle Size | Fine, uniform micro-particles | Coarser, irregular grains |

| Shape | Flat, flaky particles | Angular, rough particles |

| Surface Area | High surface area | Lower surface area |

| Purity | Typically higher purity | Varies, often lower purity |

| Applications | Lubricants, batteries, coatings, conductive additives | Refractories, brake linings, foundry facings |

| Thermal Conductivity | Excellent heat dissipation | Good heat resistance |

| Cost | Higher cost due to processing | Lower cost, less processing |

| Milling Process | Mechanically ground to fine powder | Minimal grinding, natural particle size retained |

Introduction to Graphite Material Types

Milled graphite consists of fine, uniform particles produced through mechanical milling, offering enhanced surface area and reactivity compared to granular graphite, which features coarser, irregular particles obtained by crushing natural graphite ore. The particle size and morphology of milled graphite improve its dispersion and binding properties in composite materials, whereas granular graphite maintains superior thermal conductivity due to its larger flake structure. Selecting between milled and granular graphite depends on application requirements such as electrical conductivity, lubrication, or refractory performance.

What is Milled Graphite?

Milled graphite is a finely ground form of natural graphite produced by mechanically pulverizing larger graphite particles into micron-sized powders. This process enhances surface area and reactivity, making milled graphite ideal for applications such as battery anodes, conductive coatings, and lubricants. Compared to granular graphite, milled graphite offers improved uniformity and dispersion properties critical for high-performance industrial uses.

What is Granular Graphite?

Granular graphite consists of small, naturally occurring graphite flakes mined from high-grade deposits, retaining a crystallized structure that provides excellent conductivity and lubricity. It is commonly used in refractory applications, batteries, and as a lubricant due to its thermal stability and chemical inertness. Unlike milled graphite, granular graphite requires minimal processing, preserving its natural particle size and shape, which enhances its performance in industrial uses.

Key Differences Between Milled and Granular Graphite

Milled graphite has a much finer particle size compared to granular graphite, resulting in higher surface area and enhanced dispersibility in applications like lubricants and batteries. Granular graphite retains its natural flake-like shape with larger particles, making it suitable for refractory materials and brake linings where structural integrity is critical. The distinct morphological and physical properties directly influence their performance and selection in various industrial processes.

Physical Properties Comparison

Milled graphite exhibits finer particle size and higher surface area compared to granular graphite, enhancing its dispersion and lubricity in applications. Granular graphite features larger, irregular particles with superior thermal conductivity and electrical resistance, making it suitable for refractory and battery purposes. The physical density of milled graphite is generally lower due to its powder-like texture, while granular graphite offers greater mechanical strength and stability in high-temperature environments.

Industrial Applications of Milled Graphite

Milled graphite is widely utilized in industrial applications such as lubricants, battery anodes, and conductive polymers due to its fine particle size and high purity, which enhance performance and consistency. Unlike granular graphite, milled graphite offers superior dispersion and uniformity, making it ideal for high-precision manufacturing processes in automotive, aerospace, and electronics industries. Its excellent thermal conductivity and chemical stability support advanced applications in refractory materials and seals under extreme operating conditions.

Industrial Uses for Granular Graphite

Granular graphite exhibits enhanced fluidity and purity, making it ideal for industrial applications such as refractories, lubricants, and batteries. Its particle size distribution allows for superior packing density and consistency in casting and molding processes. Industries leverage granular graphite to improve thermal conductivity and electrical performance in advanced manufacturing.

Performance Advantages: Milled vs Granular Graphite

Milled graphite offers superior performance advantages over granular graphite due to its finer particle size, which enhances dispersion and increases surface area for improved thermal and electrical conductivity. The uniform size of milled graphite ensures consistent rheological properties in composite materials, leading to better mechanical strength and durability. Granular graphite, with its larger particles, often results in lower reactivity and reduced effectiveness in high-performance applications where uniformity and precise control are critical.

Cost Considerations and Economic Factors

Milled graphite typically incurs higher production costs due to the extensive grinding and processing required, impacting its market price compared to granular graphite. Granular graphite, being less refined, offers cost advantages by minimizing energy and labor expenditures during manufacturing, making it more economically viable for bulk applications. When evaluating total cost of ownership, factors such as performance efficiency and material yield also influence the economic decision between milled and granular graphite options.

Choosing the Right Graphite Type for Your Application

Choosing the right graphite type depends on the specific application requirements, with milled graphite offering finer particle size ideal for use in batteries, lubricants, and conductive coatings due to its enhanced surface area and reactivity. Granular graphite, characterized by larger particle size, is preferred in refractory applications, foundries, and brake linings for its excellent thermal conductivity and structural integrity. Understanding the particle size and material properties of milled versus granular graphite ensures optimal performance and cost-efficiency in industrial processes.

Milled Graphite vs Granular Graphite Infographic

materialdif.com

materialdif.com