Molded graphite offers a consistent structure with excellent thermal conductivity and corrosion resistance, making it ideal for sealing applications in harsh environments. Machined graphite provides precise dimensional accuracy and a smoother surface finish, suitable for custom components requiring tight tolerances. Choosing between molded and machined graphite depends on the specific performance requirements and cost considerations of the application.

Table of Comparison

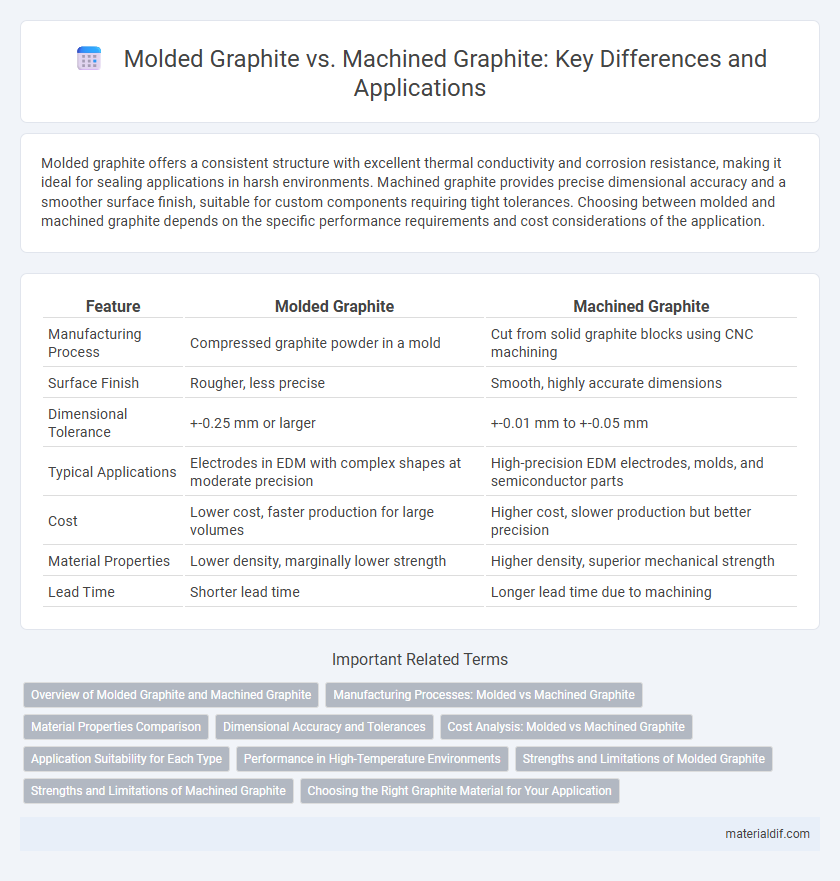

| Feature | Molded Graphite | Machined Graphite |

|---|---|---|

| Manufacturing Process | Compressed graphite powder in a mold | Cut from solid graphite blocks using CNC machining |

| Surface Finish | Rougher, less precise | Smooth, highly accurate dimensions |

| Dimensional Tolerance | +-0.25 mm or larger | +-0.01 mm to +-0.05 mm |

| Typical Applications | Electrodes in EDM with complex shapes at moderate precision | High-precision EDM electrodes, molds, and semiconductor parts |

| Cost | Lower cost, faster production for large volumes | Higher cost, slower production but better precision |

| Material Properties | Lower density, marginally lower strength | Higher density, superior mechanical strength |

| Lead Time | Shorter lead time | Longer lead time due to machining |

Overview of Molded Graphite and Machined Graphite

Molded graphite is produced by compressing fine graphite powders with binders into desired shapes, enabling cost-effective mass production of complex components with high density and mechanical strength. Machined graphite starts as large, dense graphite blocks that are precisely cut and shaped using CNC machining for superior surface finish, dimensional accuracy, and tailored geometries in critical applications. Both types offer excellent thermal conductivity and chemical resistance, with molded graphite preferred for intricate designs at scale and machined graphite favored for custom, precision-engineered parts.

Manufacturing Processes: Molded vs Machined Graphite

Molded graphite is produced by compressing graphite powder mixed with a binder into a specific shape and then curing it, allowing for high-volume production of complex geometries with consistent density. Machined graphite starts as large, dense graphite blocks that are precision cut and shaped using CNC machines, enabling tighter tolerances and smoother surface finishes. The choice between molded and machined graphite impacts product performance, cost, and scalability in applications like electrodes, seals, and heat exchangers.

Material Properties Comparison

Molded graphite offers higher density and improved mechanical strength compared to machined graphite, resulting in better wear resistance and durability. Machined graphite features superior dimensional precision and finer surface finish, essential for complex geometries and tight tolerances. The thermal conductivity of molded graphite is typically lower than machined graphite due to its porosity differences, impacting heat dissipation in high-temperature applications.

Dimensional Accuracy and Tolerances

Molded graphite typically offers moderate dimensional accuracy with tolerances around +-0.005 inches, suitable for less complex geometries. Machined graphite achieves higher dimensional precision, with tolerances as tight as +-0.0005 inches, making it ideal for applications requiring intricate detailing and stringent fits. The superior dimensional accuracy of machined graphite results from controlled machining processes, whereas molded graphite depends on mold design and material shrinkage factors.

Cost Analysis: Molded vs Machined Graphite

Molded graphite typically offers lower production costs due to its ability to form complex shapes in a single pressing process, reducing labor and waste compared to machined graphite. Machined graphite involves higher expenses driven by longer machining times and material removal, resulting in increased tool wear and labor costs. Cost analysis favors molded graphite for high-volume applications, while machined graphite is preferred for low-volume, high-precision parts despite its higher price point.

Application Suitability for Each Type

Molded graphite is ideal for high-volume manufacturing applications due to its uniform density, excellent thermal conductivity, and corrosion resistance, making it suitable for furnace components and heat exchangers. Machined graphite offers superior dimensional accuracy and surface finish, which is essential for precision parts in semiconductor manufacturing, vacuum furnace components, and aerospace industries. The choice between molded and machined graphite depends on required tolerances, production volume, and specific operational environments.

Performance in High-Temperature Environments

Molded graphite exhibits superior thermal shock resistance and dimensional stability compared to machined graphite, making it ideal for extreme high-temperature environments. Its isotropic structure enables uniform heat distribution, reducing the risk of warping or cracking under thermal stress. Machined graphite offers precision but may have anisotropic properties that limit performance in fluctuating temperatures.

Strengths and Limitations of Molded Graphite

Molded graphite offers excellent mechanical strength and is highly resistant to thermal shock, making it ideal for high-temperature applications where durability is critical. Its porosity can be controlled during production, improving chemical resistance but generally resulting in lower density and strength compared to machined graphite. Molded graphite's limitations include less precise dimensional tolerances and reduced uniformity, which can impact applications requiring tight machining specifications.

Strengths and Limitations of Machined Graphite

Machined graphite offers superior dimensional precision and smoother surface finishes compared to molded graphite, making it ideal for applications requiring tight tolerances and intricate detailing. Its strength lies in enhanced mechanical stability and better thermal conductivity, but it is limited by higher manufacturing costs and longer production times due to complex machining processes. Despite these constraints, machined graphite excels in semiconductor, aerospace, and high-performance engineering sectors where accuracy and material properties are critical.

Choosing the Right Graphite Material for Your Application

Molded graphite offers superior machinability and is ideal for complex shapes with tight tolerances, making it suitable for precision components in aerospace and semiconductor industries. Machined graphite provides higher density and enhanced thermal conductivity, preferred for high-temperature applications such as furnace components and electrical contacts. Selecting the right graphite material depends on factors like mechanical strength, thermal properties, and cost-effectiveness relative to your specific manufacturing requirements.

Molded Graphite vs Machined Graphite Infographic

materialdif.com

materialdif.com