Natural flake graphite offers high purity and excellent lubricity due to its layered crystal structure, making it ideal for applications like battery anodes and lubricants. Synthetic spherical graphite, produced through advanced manufacturing processes, provides uniform particle size and shape, enhancing performance consistency in lithium-ion batteries. Choosing between natural flake and synthetic spherical graphite depends on balancing cost efficiency with material performance requirements in energy storage technologies.

Table of Comparison

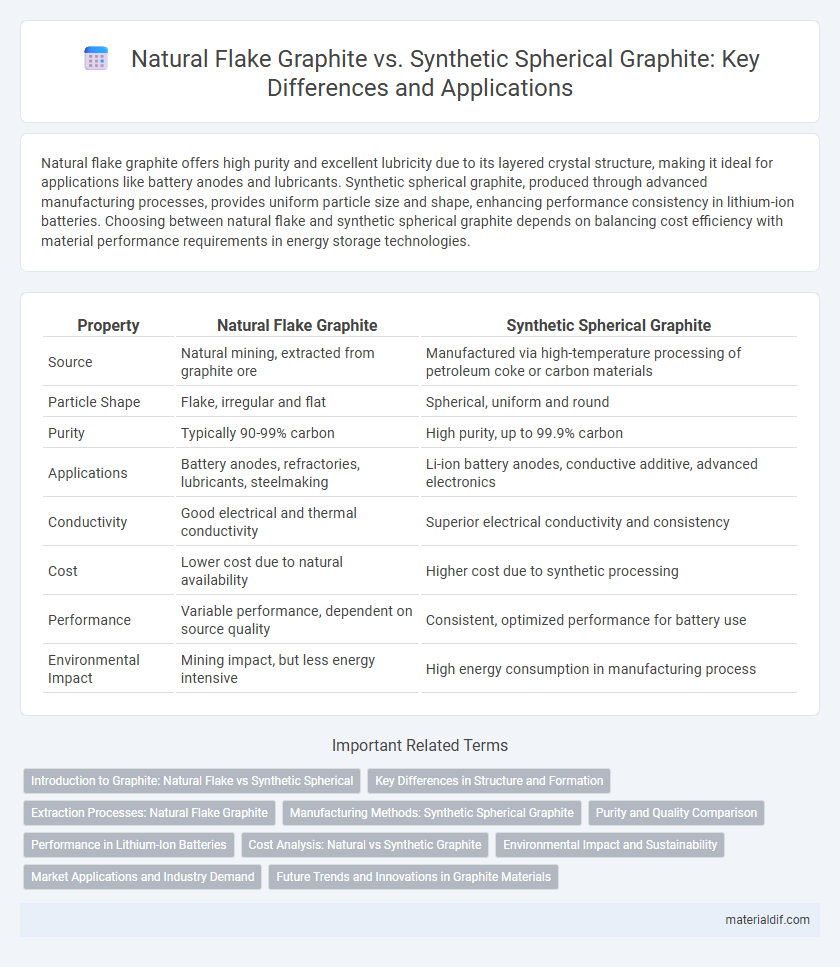

| Property | Natural Flake Graphite | Synthetic Spherical Graphite |

|---|---|---|

| Source | Natural mining, extracted from graphite ore | Manufactured via high-temperature processing of petroleum coke or carbon materials |

| Particle Shape | Flake, irregular and flat | Spherical, uniform and round |

| Purity | Typically 90-99% carbon | High purity, up to 99.9% carbon |

| Applications | Battery anodes, refractories, lubricants, steelmaking | Li-ion battery anodes, conductive additive, advanced electronics |

| Conductivity | Good electrical and thermal conductivity | Superior electrical conductivity and consistency |

| Cost | Lower cost due to natural availability | Higher cost due to synthetic processing |

| Performance | Variable performance, dependent on source quality | Consistent, optimized performance for battery use |

| Environmental Impact | Mining impact, but less energy intensive | High energy consumption in manufacturing process |

Introduction to Graphite: Natural Flake vs Synthetic Spherical

Natural flake graphite is mined directly from graphite-rich deposits and retains a layered, flaky structure that provides excellent electrical conductivity and thermal resistance, making it ideal for applications like batteries and lubricants. In contrast, synthetic spherical graphite is manufactured through high-temperature processing to create uniform, rounded particles that enhance performance in lithium-ion battery anodes by improving packing density and charge capacity. The fundamental differences in origin, morphology, and material properties between natural flake and synthetic spherical graphite determine their specific industrial uses and cost-effectiveness.

Key Differences in Structure and Formation

Natural flake graphite forms through metamorphic processes, resulting in layered, crystalline flakes with high purity and excellent electrical conductivity. Synthetic spherical graphite is produced via high-temperature processing and chemical treatments, yielding uniform, spherical particles optimized for battery anodes and electrochemical applications. The structural difference--planar flakes versus engineered spheres--directly impacts their performance characteristics in industrial and energy storage technologies.

Extraction Processes: Natural Flake Graphite

Natural flake graphite is extracted through conventional mining methods including open-pit and underground mining, followed by crushing and flotation to concentrate the graphite flakes. The process emphasizes careful handling to preserve the integrity of the flakes' crystalline structure, which is crucial for applications requiring high conductivity and lubrication properties. This extraction approach contrasts with synthetic spherical graphite, which is produced chemically rather than mined, highlighting differences in cost, purity, and environmental impact.

Manufacturing Methods: Synthetic Spherical Graphite

Synthetic spherical graphite is produced through a complex manufacturing process involving the purification of natural flake graphite followed by high-temperature thermal treatment and spheroidization using specialized milling equipment. This method enhances the material's electrochemical properties, making it suitable for lithium-ion battery anodes. Controlled pelletizing and coating techniques during fabrication further improve conductivity and cycling stability in energy storage applications.

Purity and Quality Comparison

Natural flake graphite typically exhibits a purity level ranging from 85% to 95% carbon content, with quality heavily dependent on the source and refinement methods used, often containing impurities such as quartz and silicates. Synthetic spherical graphite, produced through high-temperature processing of petroleum coke, achieves purity levels exceeding 99.9%, offering consistent particle size and morphology critical for high-performance applications like lithium-ion batteries. The superior uniformity and higher carbon purity of synthetic spherical graphite make it more suitable for advanced energy storage technologies, whereas natural flake graphite remains favored for applications where cost is a significant factor.

Performance in Lithium-Ion Batteries

Natural flake graphite exhibits high electrical conductivity and excellent cycle stability, making it a preferred anode material in lithium-ion batteries for enhancing energy density. Synthetic spherical graphite offers superior tap density and uniform particle size, contributing to faster charge rates and improved rate capability. Performance optimization in lithium-ion batteries depends on the balance between the high capacity of natural flake graphite and the rate performance advantages of synthetic spherical graphite.

Cost Analysis: Natural vs Synthetic Graphite

Natural flake graphite typically incurs lower production costs due to abundant raw materials and less energy-intensive processing compared to synthetic spherical graphite, which requires high-temperature graphitization and complex shaping processes. The price disparity is influenced by natural graphite's reliance on mining and milling, whereas synthetic graphite demands expensive precursor materials like petroleum coke and substantial manufacturing infrastructure. Cost analysis reveals natural flake graphite as economically favorable for bulk applications, while synthetic spherical graphite offers higher performance at a premium, driving strategic selection based on application needs and budget constraints.

Environmental Impact and Sustainability

Natural flake graphite extraction involves mining activities that can lead to habitat disruption, water pollution, and significant carbon emissions, while synthetic spherical graphite production relies on energy-intensive processes using fossil fuels, resulting in higher greenhouse gas emissions. Recycling and purification methods for natural flake graphite improve its sustainability profile by reducing waste and minimizing chemical usage. Advances in cleaner production technologies and the development of bio-based precursors aim to reduce the environmental impact associated with synthetic spherical graphite manufacturing.

Market Applications and Industry Demand

Natural flake graphite is extensively utilized in refractories, batteries, and expandable graphite due to its layered crystalline structure and high purity, driving strong demand in automotive and steel industries. Synthetic spherical graphite, engineered for uniform particle size and enhanced electrochemical performance, dominates the lithium-ion battery anode market, particularly for electric vehicles and energy storage systems. Increasing adoption of electric vehicles and renewable energy solutions fuels rising demand for synthetic spherical graphite, while natural flake graphite maintains significant applications in traditional industrial sectors.

Future Trends and Innovations in Graphite Materials

Natural flake graphite continues to dominate in applications requiring high conductivity and thermal stability, but synthetic spherical graphite is rapidly gaining traction in lithium-ion battery anodes due to its uniform particle size and enhanced electrochemical performance. Innovations in surface coating technologies and micronization are improving the energy density and charging rates of synthetic spherical graphite, positioning it as a critical material for next-generation electric vehicle batteries. Future trends suggest a shift towards hybrid graphite materials that combine the high purity of synthetic graphite with the scalability and cost benefits of natural flake graphite to meet the growing demands of renewable energy storage and advanced electronics.

Natural Flake Graphite vs Synthetic Spherical Graphite Infographic

materialdif.com

materialdif.com