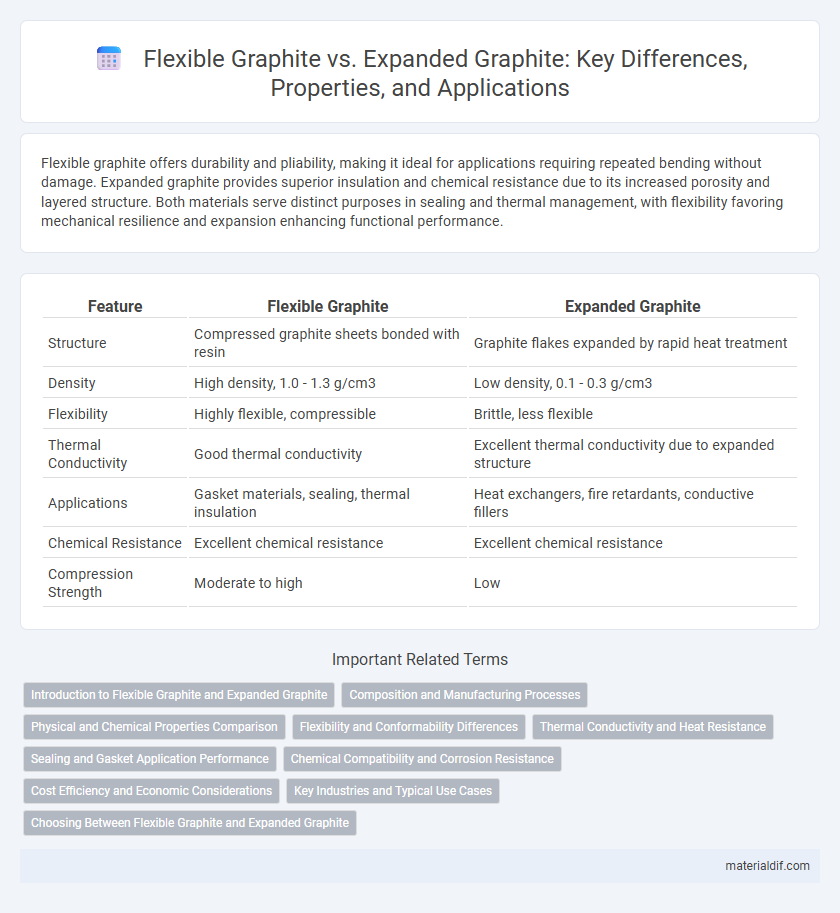

Flexible graphite offers durability and pliability, making it ideal for applications requiring repeated bending without damage. Expanded graphite provides superior insulation and chemical resistance due to its increased porosity and layered structure. Both materials serve distinct purposes in sealing and thermal management, with flexibility favoring mechanical resilience and expansion enhancing functional performance.

Table of Comparison

| Feature | Flexible Graphite | Expanded Graphite |

|---|---|---|

| Structure | Compressed graphite sheets bonded with resin | Graphite flakes expanded by rapid heat treatment |

| Density | High density, 1.0 - 1.3 g/cm3 | Low density, 0.1 - 0.3 g/cm3 |

| Flexibility | Highly flexible, compressible | Brittle, less flexible |

| Thermal Conductivity | Good thermal conductivity | Excellent thermal conductivity due to expanded structure |

| Applications | Gasket materials, sealing, thermal insulation | Heat exchangers, fire retardants, conductive fillers |

| Chemical Resistance | Excellent chemical resistance | Excellent chemical resistance |

| Compression Strength | Moderate to high | Low |

Introduction to Flexible Graphite and Expanded Graphite

Flexible graphite, also known as compressed graphite, is produced by compressing natural graphite flakes into sheets that exhibit excellent flexibility, high thermal conductivity, and superior chemical resistance, making it suitable for gasketing and sealing applications. Expanded graphite is created by rapidly heating natural graphite flakes, causing them to separate and form a worm-like structure with high porosity and low density, which is ideal for insulation, absorbents, and lightweight fillers. Both forms derive from natural graphite but differ in processing and physical properties, influencing their specific industrial uses and performance characteristics.

Composition and Manufacturing Processes

Flexible graphite is primarily composed of natural graphite flakes subjected to high-pressure compression and exfoliation, resulting in a dense, pliable material with enhanced mechanical strength. Expanded graphite is produced by rapid heating of intercalated graphite, causing the layers to separate and form a low-density, porous structure with increased surface area. The key difference lies in flexible graphite's compression-based lamination versus expanded graphite's thermal expansion method, influencing their respective applications and physical properties.

Physical and Chemical Properties Comparison

Flexible graphite exhibits high compressibility and excellent chemical resistance, making it suitable for sealing applications subject to cyclic pressure changes. Expanded graphite features a lower density and enhanced thermal conductivity due to its exfoliated structure, which provides greater flexibility and adaptability in thermal management systems. Both materials demonstrate outstanding corrosion resistance, but flexible graphite offers superior mechanical strength and resilience under mechanical stress compared to expanded graphite.

Flexibility and Conformability Differences

Flexible graphite exhibits superior flexibility due to its compressed and compacted structure, allowing it to bend and conform to irregular surfaces without cracking. Expanded graphite, created by exfoliating graphite flakes, provides increased surface area but lacks the same level of pliability, making it less conformable under mechanical stress. These material distinctions influence their applications, with flexible graphite preferred for sealing and gasketing where adaptability to uneven surfaces is critical.

Thermal Conductivity and Heat Resistance

Flexible graphite offers superior thermal conductivity, ranging between 100 to 150 W/m*K, making it ideal for efficient heat dissipation in industrial applications, while its heat resistance can withstand temperatures up to 500degC in an oxidizing environment. Expanded graphite, although similar in structure, typically has slightly lower thermal conductivity, around 80 to 120 W/m*K, and excels in heat resistance by tolerating temperatures up to 700degC due to its expanded laminar layers improving thermal stability. These properties make flexible graphite preferred for applications requiring high thermal transfer, while expanded graphite is better suited for high-temperature insulation and sealing.

Sealing and Gasket Application Performance

Flexible graphite exhibits superior sealing performance in gasket applications due to its enhanced compressibility and resilience, allowing it to conform effectively to flange surfaces and maintain tight seals under varying pressures and temperatures. Expanded graphite offers excellent thermal stability and chemical resistance but tends to have lower mechanical strength, which can impact long-term gasket durability in dynamic sealing environments. Both materials deliver high corrosion resistance and thermal conductivity, yet flexible graphite is often preferred for critical sealing tasks requiring reliable performance over extended service periods.

Chemical Compatibility and Corrosion Resistance

Flexible graphite exhibits superior chemical compatibility and corrosion resistance compared to expanded graphite due to its dense, layered structure that minimizes fluid penetration and chemical attack. Expanded graphite's porous, spongy texture allows for greater chemical absorption, which can compromise its durability in highly aggressive chemical environments. Industries requiring robust corrosion-resistant materials often prefer flexible graphite for sealing and gasketing applications involving strong acids, alkalis, and solvents.

Cost Efficiency and Economic Considerations

Flexible graphite offers lower production costs due to its simpler manufacturing process involving the compression of natural graphite flakes, making it ideal for applications requiring cost efficiency. Expanded graphite, produced by thermal expansion of graphite flakes, incurs higher costs but provides enhanced flexibility and sealing properties that justify the investment in high-performance sealing and gasketing applications. Choosing between flexible and expanded graphite depends on balancing budget constraints with the desired material performance and longevity in industrial uses.

Key Industries and Typical Use Cases

Flexible graphite is widely used in automotive, electronics, and aerospace industries due to its excellent thermal conductivity and mechanical flexibility, making it ideal for gaskets, heat exchangers, and seals. Expanded graphite, with its high surface area and chemical resistance, is favored in chemical processing, energy storage, and environmental applications, particularly for battery electrodes, thermal insulation, and corrosion-resistant linings. Both materials offer unique advantages tailored to specific industrial needs, enhancing performance in demanding environments.

Choosing Between Flexible Graphite and Expanded Graphite

Flexible graphite offers superior compression resistance and excellent sealing performance, making it ideal for high-pressure gasket applications. Expanded graphite features a low density and high thermal conductivity, which enhances heat dissipation in heat exchangers and battery packs. Selecting between flexible graphite and expanded graphite depends on the specific requirements of mechanical strength, thermal management, and chemical resistance in industrial applications.

Flexible Graphite vs Expanded Graphite Infographic

materialdif.com

materialdif.com