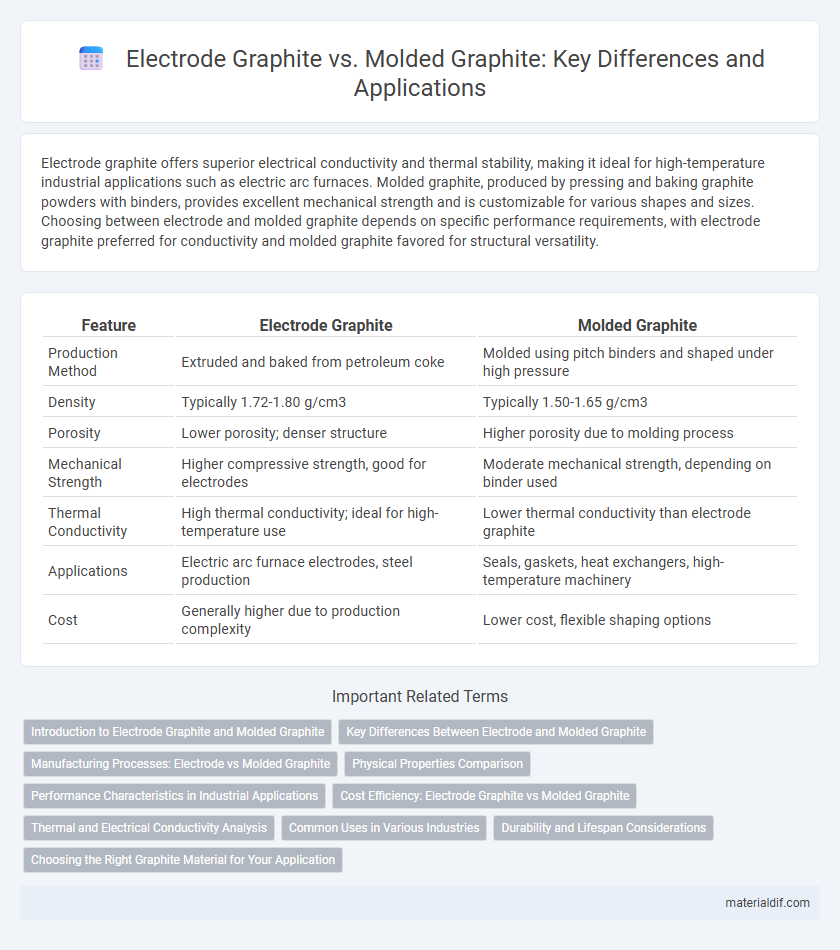

Electrode graphite offers superior electrical conductivity and thermal stability, making it ideal for high-temperature industrial applications such as electric arc furnaces. Molded graphite, produced by pressing and baking graphite powders with binders, provides excellent mechanical strength and is customizable for various shapes and sizes. Choosing between electrode and molded graphite depends on specific performance requirements, with electrode graphite preferred for conductivity and molded graphite favored for structural versatility.

Table of Comparison

| Feature | Electrode Graphite | Molded Graphite |

|---|---|---|

| Production Method | Extruded and baked from petroleum coke | Molded using pitch binders and shaped under high pressure |

| Density | Typically 1.72-1.80 g/cm3 | Typically 1.50-1.65 g/cm3 |

| Porosity | Lower porosity; denser structure | Higher porosity due to molding process |

| Mechanical Strength | Higher compressive strength, good for electrodes | Moderate mechanical strength, depending on binder used |

| Thermal Conductivity | High thermal conductivity; ideal for high-temperature use | Lower thermal conductivity than electrode graphite |

| Applications | Electric arc furnace electrodes, steel production | Seals, gaskets, heat exchangers, high-temperature machinery |

| Cost | Generally higher due to production complexity | Lower cost, flexible shaping options |

Introduction to Electrode Graphite and Molded Graphite

Electrode graphite, primarily used in electric arc furnaces, is manufactured by baking and graphitizing needle coke to create a highly conductive, dense material ideal for efficient electrical current flow. Molded graphite is produced by mixing natural or synthetic graphite with a binder, then molding and baking the composite to form complex shapes with high thermal stability and chemical resistance. Both types serve critical roles in industrial applications, with electrode graphite optimized for electrical conductivity and molded graphite tailored for mechanical strength and versatility.

Key Differences Between Electrode and Molded Graphite

Electrode graphite is primarily fabricated through extrusion and baking processes, resulting in high electrical conductivity and uniform microstructure ideal for electric arc furnaces. Molded graphite, produced by compressing graphite powder under high pressure, offers superior mechanical strength and is often used where complex shapes and thermal resistance are required. Key differences include electrode graphite's emphasis on conductivity and purity versus molded graphite's versatility in form and enhanced durability.

Manufacturing Processes: Electrode vs Molded Graphite

Electrode graphite is manufactured through a process involving the mixing of petroleum coke and coal tar pitch, followed by extrusion, baking, impregnation, and graphitization at high temperatures to enhance density and conductivity. Molded graphite is produced by compressing graphite powder with a binder into a desired shape, then baking and graphitizing it, allowing for complex geometries and faster production cycles. The manufacturing process of electrode graphite emphasizes grain orientation and strength for electrical conductivity, while molded graphite focuses on shaping flexibility and controlled porosity.

Physical Properties Comparison

Electrode graphite exhibits higher density and superior electrical conductivity compared to molded graphite, making it ideal for high current applications. Molded graphite typically has lower mechanical strength but better machinability due to its porous structure. Thermal stability in electrode graphite surpasses molded graphite, allowing it to withstand elevated temperatures in industrial processes.

Performance Characteristics in Industrial Applications

Electrode graphite exhibits superior electrical conductivity and thermal stability compared to molded graphite, making it ideal for high-temperature applications such as electric arc furnaces and metallurgical processes. Molded graphite offers greater mechanical strength and dimensional stability, suitable for components requiring precise machining and structural durability in industrial equipment. The choice between electrode and molded graphite hinges on optimizing performance metrics like conductivity, heat resistance, and mechanical strength for specific industrial applications.

Cost Efficiency: Electrode Graphite vs Molded Graphite

Electrode graphite offers superior cost efficiency compared to molded graphite due to its higher electrical conductivity and durability, reducing frequency of replacement and maintenance costs in high-temperature applications. Molded graphite, while less expensive upfront, often incurs higher operational expenses because of lower thermal resistance and shorter service life. The total cost of ownership strongly favors electrode graphite in industries requiring long-lasting performance under extreme conditions.

Thermal and Electrical Conductivity Analysis

Electrode graphite exhibits higher electrical conductivity, typically around 150-200 S/cm, due to its dense and anisotropic microstructure optimized for current-carrying applications, while molded graphite offers lower conductivity, approximately 50-100 S/cm, attributed to its isotropic but porous form. In thermal conductivity, electrode graphite often reaches values near 100-130 W/m*K, facilitating efficient heat dissipation in high-temperature processes, whereas molded graphite shows reduced thermal conductivity around 40-70 W/m*K due to its increased porosity. These distinct conductivity characteristics influence the choice of material in industrial applications where precise thermal management and electrical performance are critical.

Common Uses in Various Industries

Electrode graphite is primarily used in electric arc furnaces for steel production and in aluminum smelting due to its excellent electrical conductivity and high-temperature resistance. Molded graphite finds common applications in the chemical industry for seals, gaskets, and heat exchangers, benefiting from its superior thermal stability and corrosion resistance. Both types serve critical roles in industries such as metallurgy, electronics, and aerospace, optimizing performance in extreme operational environments.

Durability and Lifespan Considerations

Electrode graphite exhibits higher durability due to its dense, uniform grain structure, which enhances resistance to thermal shock and mechanical wear in high-temperature applications. Molded graphite, while easier to shape, often contains higher porosity levels that can reduce lifespan under continuous thermal cycling and aggressive chemical exposure. Selecting electrode graphite typically ensures longer service life in industrial processes requiring sustained performance and minimal material degradation.

Choosing the Right Graphite Material for Your Application

Electrode graphite offers superior electrical conductivity and thermal stability, making it ideal for high-temperature applications such as electric arc furnaces and battery electrodes. Molded graphite provides enhanced mechanical strength and dimensional stability, suitable for complex shapes and precision machined components in aerospace and chemical industries. Selecting the right graphite material depends on specific application requirements including conductivity, thermal resistance, mechanical strength, and manufacturability to optimize performance and cost-effectiveness.

Electrode Graphite vs Molded Graphite Infographic

materialdif.com

materialdif.com