Clay graphite contains a mixture of natural graphite and clay, which enhances its strength and reduces smudging, making it ideal for general writing and sketching purposes. Pure graphite, on the other hand, consists almost entirely of graphite particles, providing a softer, darker mark preferred by artists for shading and detailed drawing. The choice between clay graphite and pure graphite depends on the desired hardness, darkness, and application in writing or artistic work.

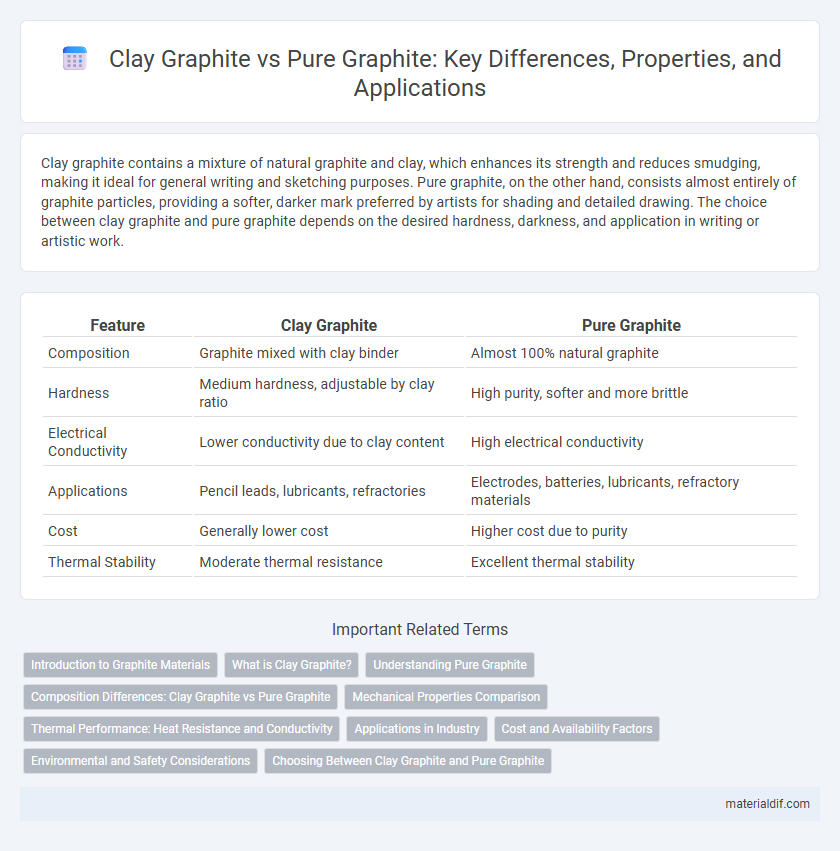

Table of Comparison

| Feature | Clay Graphite | Pure Graphite |

|---|---|---|

| Composition | Graphite mixed with clay binder | Almost 100% natural graphite |

| Hardness | Medium hardness, adjustable by clay ratio | High purity, softer and more brittle |

| Electrical Conductivity | Lower conductivity due to clay content | High electrical conductivity |

| Applications | Pencil leads, lubricants, refractories | Electrodes, batteries, lubricants, refractory materials |

| Cost | Generally lower cost | Higher cost due to purity |

| Thermal Stability | Moderate thermal resistance | Excellent thermal stability |

Introduction to Graphite Materials

Clay graphite, also known as impurity-rich or natural graphite, contains significant non-carbon elements such as clay minerals, which influence its electrical conductivity and thermal properties. Pure graphite is characterized by a high carbon content exceeding 99%, offering superior conductivity, lubricity, and chemical stability important for advanced industrial applications. Understanding the differences between clay and pure graphite is essential for selecting the right material in manufacturing electrodes, refractories, and batteries.

What is Clay Graphite?

Clay graphite is a composite material consisting of natural graphite combined with a clay binder, which enhances its mechanical strength and machinability. Unlike pure graphite, clay graphite contains graphite particles embedded in a clay matrix, making it more durable for applications such as pencils and refractory materials. The clay binder influences properties like hardness, density, and thermal conductivity, differentiating clay graphite from high-purity graphite used in advanced industrial processes.

Understanding Pure Graphite

Pure graphite consists almost entirely of carbon atoms arranged in a hexagonal crystal lattice, providing exceptional electrical conductivity, thermal stability, and chemical inertness. Unlike clay graphite, which contains a significant amount of clay filler affecting its hardness and conductivity, pure graphite offers superior performance in high-temperature applications and advanced electronics. The isotropic structure of pure graphite ensures uniform properties, making it ideal for industrial uses such as electrodes, heat exchangers, and lubricants.

Composition Differences: Clay Graphite vs Pure Graphite

Clay graphite contains a significant amount of clay and other minerals mixed with graphite, resulting in a composite material with varied physical and chemical properties. Pure graphite, on the other hand, consists almost entirely of crystallized carbon atoms arranged in a hexagonal lattice, providing superior electrical conductivity and thermal stability. The high carbon content in pure graphite distinguishes it from clay graphite, which typically contains 30-50% graphite and the remainder as clay and binding agents.

Mechanical Properties Comparison

Clay graphite exhibits higher hardness and improved wear resistance due to its abundant impurities and inclusions, making it suitable for applications requiring mechanical durability. Pure graphite, characterized by its crystalline structure and higher purity, offers superior lubrication properties but lower mechanical strength compared to clay graphite. The mechanical properties of clay graphite include greater compressive strength and fracture toughness, whereas pure graphite excels in thermal conductivity and electrical stability.

Thermal Performance: Heat Resistance and Conductivity

Clay graphite exhibits lower thermal conductivity and reduced heat resistance compared to pure graphite due to the presence of non-conductive clay impurities, which disrupt the lattice structure and impede heat flow. Pure graphite, with its highly ordered crystalline structure, offers exceptional thermal conductivity up to 2000 W/m*K and superior heat resistance, maintaining stability at temperatures exceeding 3000degC in inert atmospheres. These properties make pure graphite the preferred material for applications requiring efficient heat dissipation and extreme thermal stability.

Applications in Industry

Clay graphite, composed of graphite mixed with clay binders, exhibits higher hardness and lower conductivity, making it ideal for mechanical applications like pencils, brake linings, and refractory materials. Pure graphite, known for its excellent electrical and thermal conductivity, is widely used in electrodes, batteries, and high-temperature industrial processes such as steel manufacturing and nuclear reactors. The distinct physical properties of clay and pure graphite determine their suitability across various industrial sectors, optimizing performance and durability.

Cost and Availability Factors

Clay graphite is more abundant and economical compared to pure graphite, which is rarer and thus commands higher prices. The manufacturing costs for clay graphite products are lower due to the easier processing of its blended composition. Availability constraints and higher extraction expenses make pure graphite less accessible and more costly for industrial applications.

Environmental and Safety Considerations

Clay graphite contains impurities that can release harmful gases during processing, posing greater environmental and safety risks compared to pure graphite. Pure graphite, with higher carbon content and fewer contaminants, produces less toxic emissions and offers better stability under high-temperature applications, reducing hazards for workers and the environment. Proper handling and disposal protocols are essential for both types, but pure graphite generally aligns better with stringent environmental regulations and workplace safety standards.

Choosing Between Clay Graphite and Pure Graphite

Clay graphite offers enhanced durability and lower production costs due to the inclusion of binders and impurities, making it ideal for industrial applications requiring cost-efficiency. Pure graphite, characterized by higher purity and superior electrical and thermal conductivity, is preferred for high-performance applications such as electrodes and battery anodes. Selecting between clay and pure graphite hinges on balancing performance requirements against budget constraints and application-specific needs.

Clay Graphite vs Pure Graphite Infographic

materialdif.com

materialdif.com