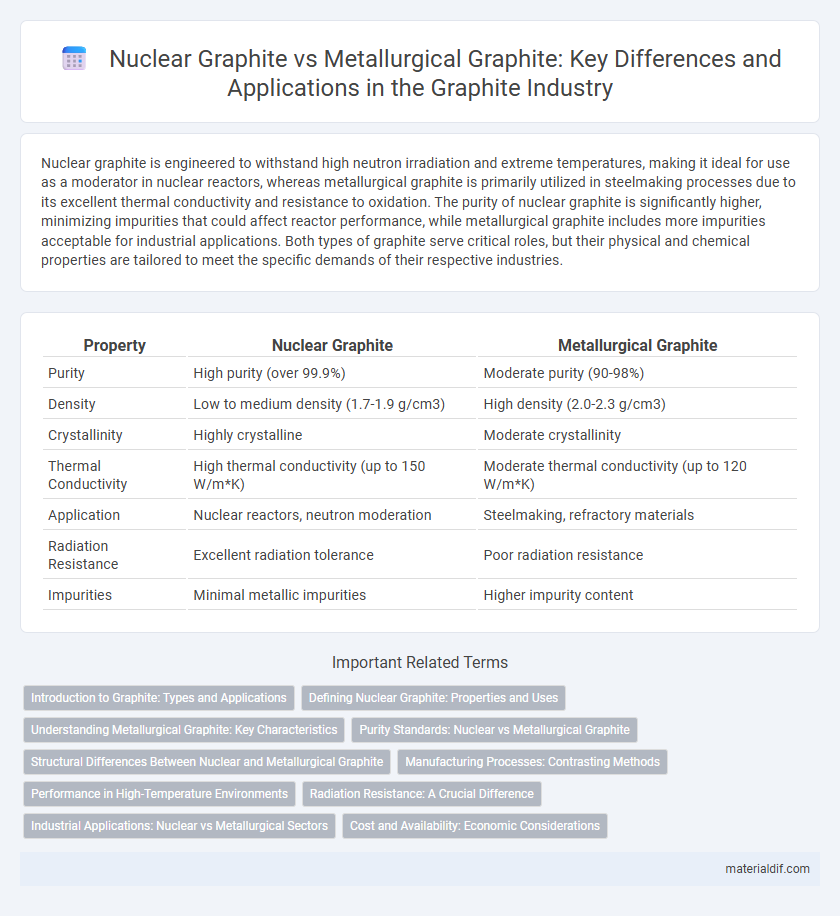

Nuclear graphite is engineered to withstand high neutron irradiation and extreme temperatures, making it ideal for use as a moderator in nuclear reactors, whereas metallurgical graphite is primarily utilized in steelmaking processes due to its excellent thermal conductivity and resistance to oxidation. The purity of nuclear graphite is significantly higher, minimizing impurities that could affect reactor performance, while metallurgical graphite includes more impurities acceptable for industrial applications. Both types of graphite serve critical roles, but their physical and chemical properties are tailored to meet the specific demands of their respective industries.

Table of Comparison

| Property | Nuclear Graphite | Metallurgical Graphite |

|---|---|---|

| Purity | High purity (over 99.9%) | Moderate purity (90-98%) |

| Density | Low to medium density (1.7-1.9 g/cm3) | High density (2.0-2.3 g/cm3) |

| Crystallinity | Highly crystalline | Moderate crystallinity |

| Thermal Conductivity | High thermal conductivity (up to 150 W/m*K) | Moderate thermal conductivity (up to 120 W/m*K) |

| Application | Nuclear reactors, neutron moderation | Steelmaking, refractory materials |

| Radiation Resistance | Excellent radiation tolerance | Poor radiation resistance |

| Impurities | Minimal metallic impurities | Higher impurity content |

Introduction to Graphite: Types and Applications

Nuclear graphite is a highly pure form of graphite specifically engineered to withstand extreme radiation and high temperatures in nuclear reactors, while metallurgical graphite is primarily used in steelmaking as a recarburizer and lubricant due to its excellent thermal conductivity and mechanical strength. The distinct structural properties of nuclear graphite, including low neutron absorption and dimensional stability under irradiation, differentiate it significantly from the more industrial-focused metallurgical graphite. These variations define their respective applications, with nuclear graphite critical in reactor cores and metallurgical graphite essential in metallurgical processes and industrial manufacturing.

Defining Nuclear Graphite: Properties and Uses

Nuclear graphite is a highly pure form of graphite characterized by low neutron absorption, high thermal conductivity, and excellent dimensional stability under irradiation, making it essential for use as a moderator and reflector in nuclear reactors. Unlike metallurgical graphite, which is primarily utilized in steelmaking and refractory applications due to its high carbon content and mechanical strength, nuclear graphite demands stringent purity and isotropic properties to withstand extreme neutron flux and high temperatures. Key applications of nuclear graphite include serving as a core structural material in gas-cooled reactors and as a neutron moderator in advanced nuclear power systems.

Understanding Metallurgical Graphite: Key Characteristics

Metallurgical graphite is characterized by its high thermal conductivity, excellent electrical conductivity, and superior resistance to thermal shock, making it essential for use in steelmaking processes. It possesses a dense, fine-grained microstructure that ensures durability and strength under extreme temperatures typical in blast furnaces and electric arc furnaces. Unlike nuclear graphite, metallurgical graphite is less purified and designed to withstand mechanical wear and chemical reactions during metallurgical applications.

Purity Standards: Nuclear vs Metallurgical Graphite

Nuclear graphite requires exceptionally high purity standards, with impurity levels often below 10 parts per million to withstand radiation and high temperatures in reactor cores. Metallurgical graphite, used primarily in steelmaking, has more lenient purity requirements, typically allowing higher levels of ash and metallic impurities. The stringent purity in nuclear graphite ensures minimal neutron absorption and maintains structural integrity under extreme operational conditions.

Structural Differences Between Nuclear and Metallurgical Graphite

Nuclear graphite exhibits a highly ordered, fine-grained microstructure with superior purity and low porosity, designed to withstand intense neutron irradiation and high temperatures within reactors. Metallurgical graphite features a coarser grain size and higher impurity levels, optimized for thermal conductivity and electrical applications rather than nuclear resilience. These structural differences, including pore distribution and crystallographic alignment, critically influence performance, making nuclear graphite suitable for core components and metallurgical graphite ideal for electrodes and lubricants.

Manufacturing Processes: Contrasting Methods

Nuclear graphite is manufactured through a high-purity, controlled process involving fine petroleum coke and coal tar pitch, followed by graphitization at temperatures above 2500degC to ensure minimal impurities and radiation stability. Metallurgical graphite is produced by combining natural flake graphite with binders and subjecting the mixture to lower-temperature baking and graphitization, focusing on electrical conductivity and thermal stability for steelmaking applications. These contrasting manufacturing processes result in nuclear graphite's superior structural integrity under neutron irradiation, while metallurgical graphite emphasizes cost-efficiency and performance in industrial smelting.

Performance in High-Temperature Environments

Nuclear graphite exhibits superior thermal stability and radiation resistance compared to metallurgical graphite, making it ideal for extreme high-temperature reactor environments. Its microstructure is specifically engineered to withstand neutron irradiation without significant dimensional changes or degradation. Metallurgical graphite, while effective for high-temperature industrial processes, lacks the resilience required for prolonged exposure to intense radiation and thermal cycling found in nuclear applications.

Radiation Resistance: A Crucial Difference

Nuclear graphite exhibits exceptional radiation resistance due to its highly ordered crystal structure and impurities that reduce neutron absorption, making it suitable for use in nuclear reactors where intense radiation exposure occurs. Metallurgical graphite, while useful for high-temperature applications and electrical conductivity, lacks this robust resistance to radiation-induced damage, limiting its performance in nuclear environments. The differential radiation tolerance is critical for selecting the appropriate graphite type in applications involving neutron irradiation and radioactive environments.

Industrial Applications: Nuclear vs Metallurgical Sectors

Nuclear graphite is specifically engineered to withstand intense neutron irradiation and high temperatures, making it ideal for use in nuclear reactor cores and neutron moderators. Metallurgical graphite, characterized by high purity and excellent thermal conductivity, is predominantly utilized in steelmaking processes as a refractory material and in electric arc furnace electrodes. While nuclear graphite prioritizes radiation resistance for safety-critical applications, metallurgical graphite excels in thermal and electrical performance for efficient metal production.

Cost and Availability: Economic Considerations

Nuclear graphite commands a higher cost due to stringent purity standards and complex manufacturing processes required for nuclear reactor applications. Metallurgical graphite is more widely available and economically efficient, benefiting from large-scale production for steelmaking and other industrial uses. The cost gap reflects the specialized properties and certifications necessary in nuclear-grade graphite, impacting overall economic feasibility.

Nuclear Graphite vs Metallurgical Graphite Infographic

materialdif.com

materialdif.com