Isostatic graphite offers superior uniformity and isotropic properties, making it ideal for complex shapes and high-stress applications, while molded graphite is typically less expensive and better suited for simpler, larger components. The manufacturing process of isostatic graphite involves pressing graphite powder under high pressure in all directions, resulting in enhanced mechanical strength and thermal conductivity compared to molded graphite. Choosing between isostatic and molded graphite depends on the required performance characteristics, cost considerations, and the specific application demands.

Table of Comparison

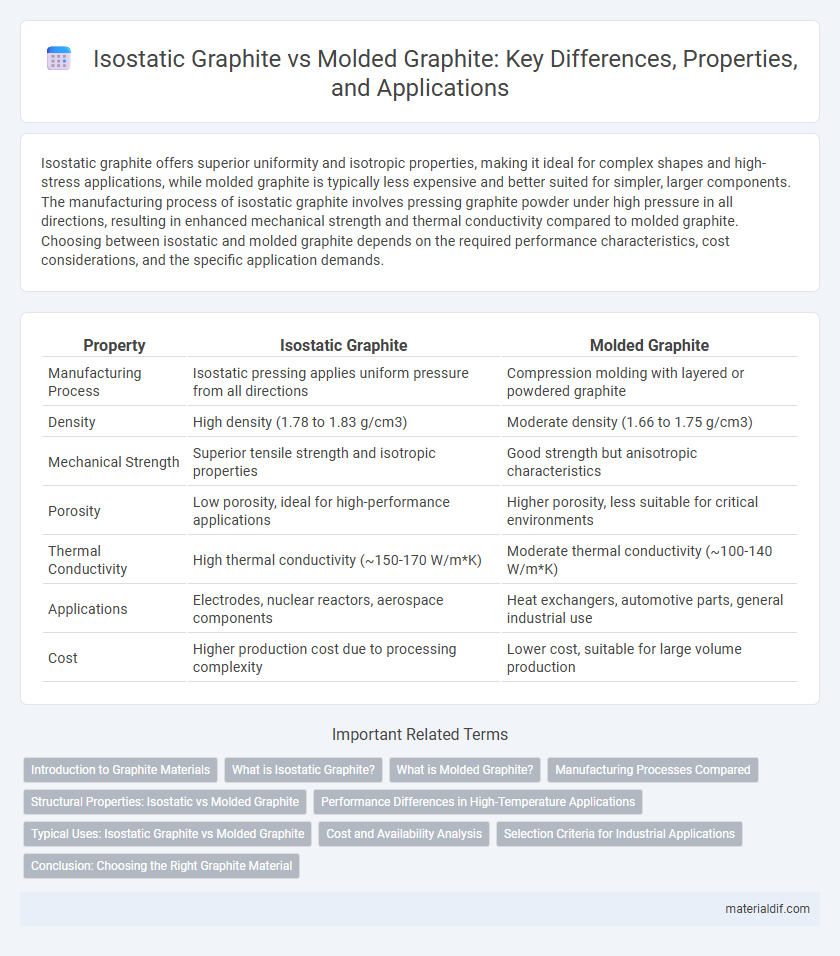

| Property | Isostatic Graphite | Molded Graphite |

|---|---|---|

| Manufacturing Process | Isostatic pressing applies uniform pressure from all directions | Compression molding with layered or powdered graphite |

| Density | High density (1.78 to 1.83 g/cm3) | Moderate density (1.66 to 1.75 g/cm3) |

| Mechanical Strength | Superior tensile strength and isotropic properties | Good strength but anisotropic characteristics |

| Porosity | Low porosity, ideal for high-performance applications | Higher porosity, less suitable for critical environments |

| Thermal Conductivity | High thermal conductivity (~150-170 W/m*K) | Moderate thermal conductivity (~100-140 W/m*K) |

| Applications | Electrodes, nuclear reactors, aerospace components | Heat exchangers, automotive parts, general industrial use |

| Cost | Higher production cost due to processing complexity | Lower cost, suitable for large volume production |

Introduction to Graphite Materials

Isostatic graphite is produced by compressing graphite powder uniformly in all directions, resulting in a material with high isotropy, excellent mechanical strength, and superior thermal conductivity. Molded graphite, formed by compacting graphite powder in a single direction, typically exhibits directional properties with good density and electrical conductivity but less uniformity. Both materials are essential in high-temperature and electrochemical applications, with isostatic graphite preferred for structural integrity and molded graphite favored for cost-effective manufacturing.

What is Isostatic Graphite?

Isostatic graphite is a highly uniform form of synthetic graphite manufactured by applying equal pressure from all directions during the pressing process, resulting in a dense, isotropic structure. This graphite variant exhibits superior mechanical strength, thermal conductivity, and chemical resistance compared to molded graphite due to its evenly distributed grain structure. Common applications of isostatic graphite include high-performance electrode manufacturing, aerospace components, and advanced thermal management systems where consistent material properties are critical.

What is Molded Graphite?

Molded graphite is a type of synthetic graphite formed by compressing fine graphite powders with binders under high pressure, resulting in dense, strong shapes suitable for complex components. This manufacturing process allows precise control over dimensions and properties, making molded graphite ideal for applications requiring intricate geometries and high thermal conductivity. Unlike isostatic graphite, molded graphite tends to have higher density but may exhibit anisotropic properties due to the pressing direction during fabrication.

Manufacturing Processes Compared

Isostatic graphite is produced by applying uniform pressure in all directions during molding, resulting in highly dense and isotropic properties ideal for precision engineering applications. Molded graphite is formed by pressing graphite powder into a desired shape using a unidirectional press, offering cost efficiency and suitable mechanical strength for general industrial uses. The isostatic process enhances homogeneity and mechanical performance, whereas molded graphite prioritizes shape flexibility and lower manufacturing costs.

Structural Properties: Isostatic vs Molded Graphite

Isostatic graphite exhibits superior isotropic structural properties, featuring uniform density, fine grain size, and enhanced mechanical strength in all directions, which makes it ideal for high-stress applications. Molded graphite, while offering good thermal conductivity and easier machining, tends to have anisotropic strength and coarser grain structure, resulting in localized weaknesses. The structural homogeneity of isostatic graphite translates to better resistance against thermal shock and mechanical wear compared to the directional variability seen in molded graphite.

Performance Differences in High-Temperature Applications

Isostatic graphite exhibits superior uniformity and mechanical strength compared to molded graphite, making it more resilient in high-temperature environments exceeding 2000degC. Its isotropic structure allows for better thermal shock resistance and dimensional stability under rapid temperature fluctuations, essential for industrial processes like heat treatment and semiconductor manufacturing. Molded graphite, while cost-effective, tends to have anisotropic properties and lower density, resulting in reduced performance and shorter lifespan under extreme thermal stress.

Typical Uses: Isostatic Graphite vs Molded Graphite

Isostatic graphite is typically used in high-performance applications such as aerospace components, nuclear reactors, and semiconductor manufacturing due to its uniform density and excellent mechanical properties. Molded graphite is commonly found in electrodes for electric arc furnaces, brake linings, and chemical processing equipment, where cost efficiency and complex shapes are prioritized. Each type serves distinct industrial needs based on their structural characteristics and performance requirements.

Cost and Availability Analysis

Isostatic graphite typically costs more than molded graphite due to its uniform density and superior mechanical properties, making it ideal for high-performance applications. Availability of isostatic graphite is often limited by more complex manufacturing processes, whereas molded graphite benefits from broader production facilities, resulting in easier procurement and lower lead times. Cost-effectiveness of molded graphite suits large-scale, less demanding uses, while isostatic graphite justifies higher prices with enhanced durability and precision.

Selection Criteria for Industrial Applications

Isostatic graphite offers greater uniformity, strength, and isotropic properties, making it ideal for high-stress or complex-shaped components in semiconductor manufacturing and aerospace industries. Molded graphite, with its cost-effectiveness and ease of shaping, suits applications requiring large parts with moderate mechanical demands, such as heat exchangers or battery electrodes. Selection criteria prioritize mechanical strength, thermal conductivity, machinability, and cost efficiency based on specific industrial performance requirements.

Conclusion: Choosing the Right Graphite Material

Isostatic graphite offers superior isotropic properties, high purity, and excellent mechanical strength, making it ideal for applications requiring uniform thermal conductivity and complex shapes. Molded graphite provides cost-effective solutions with good machinability and adequate thermal resistance, suitable for less demanding industrial uses. Selecting the right graphite material depends on specific application requirements such as thermal performance, mechanical strength, and budget constraints.

Isostatic Graphite vs Molded Graphite Infographic

materialdif.com

materialdif.com