Graphite pencils with binders offer enhanced durability and smoother application, as the binder holds the graphite particles together, allowing for consistent marks and less breakage. Pencils without binders contain pure graphite, which produces softer and darker lines but tends to crumble more easily and is less suitable for detailed work. Choosing between binders and no binders depends on the desired balance between precision, texture, and longevity in drawing or writing tasks.

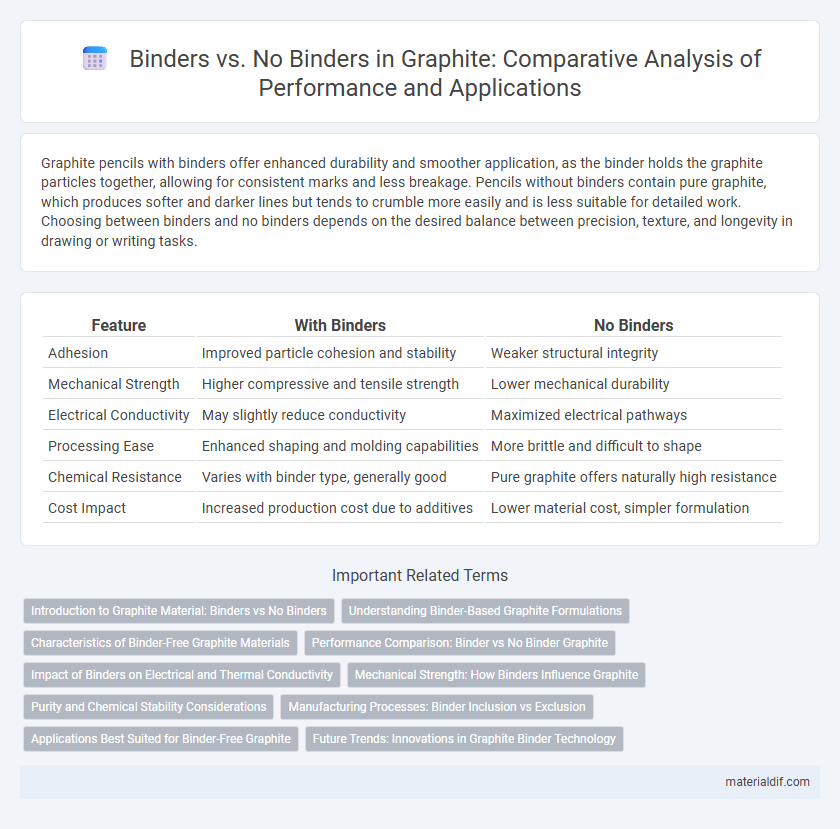

Table of Comparison

| Feature | With Binders | No Binders |

|---|---|---|

| Adhesion | Improved particle cohesion and stability | Weaker structural integrity |

| Mechanical Strength | Higher compressive and tensile strength | Lower mechanical durability |

| Electrical Conductivity | May slightly reduce conductivity | Maximized electrical pathways |

| Processing Ease | Enhanced shaping and molding capabilities | More brittle and difficult to shape |

| Chemical Resistance | Varies with binder type, generally good | Pure graphite offers naturally high resistance |

| Cost Impact | Increased production cost due to additives | Lower material cost, simpler formulation |

Introduction to Graphite Material: Binders vs No Binders

Graphite material with binders incorporates adhesive substances that enhance mechanical strength, shaping capability, and structural integrity, making it suitable for applications requiring durability and precision. In contrast, graphite without binders, often referred to as binderless graphite, offers superior purity, higher thermal conductivity, and improved resistance to chemical corrosion, ideal for high-performance industrial uses such as electrodes and aerospace components. The choice between binders and no binders in graphite materials impacts electrical conductivity, porosity, and overall performance characteristics critical to their respective applications.

Understanding Binder-Based Graphite Formulations

Binder-based graphite formulations incorporate binders to enhance mechanical strength and structural integrity, enabling improved performance in applications like lithium-ion battery anodes. These binders impact electrical conductivity and electrode flexibility, influencing the overall electrochemical efficiency and cycle stability of graphite materials. Understanding the interaction between graphite particles and various binders, such as PVDF or CMC, is crucial for optimizing formulation properties and achieving desired conductivity and durability in energy storage devices.

Characteristics of Binder-Free Graphite Materials

Binder-free graphite materials exhibit enhanced electrical conductivity and higher active material utilization due to the absence of insulating binders, resulting in improved electrode performance. These materials offer superior mechanical stability and better ion transport pathways, contributing to prolonged cycle life and faster charge-discharge rates in energy storage devices. Reduced internal resistance and increased electrode density are key characteristics that make binder-free graphite an attractive option for high-performance batteries.

Performance Comparison: Binder vs No Binder Graphite

Graphs with binder graphite exhibit enhanced mechanical stability and higher electrical conductivity compared to no binder graphite, resulting in improved electrode performance and longer cycle life. No binder graphite often shows increased porosity and faster ion diffusion but suffers from reduced structural integrity, leading to capacity fade over time. Performance benchmarks demonstrate that binder graphite provides superior volumetric capacity retention and rate capability in lithium-ion batteries.

Impact of Binders on Electrical and Thermal Conductivity

Binders in graphite composites significantly affect electrical and thermal conductivity by influencing particle contact and composite density. The presence of binders typically reduces conductivity due to their insulating properties, which disrupt electron and phonon pathways. Optimizing binder content balances mechanical integrity with maintaining high conductive performance for applications like electrodes and heat sinks.

Mechanical Strength: How Binders Influence Graphite

Binders significantly enhance the mechanical strength of graphite by improving particle cohesion and structural integrity during electrode fabrication. Without binders, graphite electrodes tend to have lower tensile strength and are more prone to cracking and damage under mechanical stress. Optimizing binder type and concentration directly influences graphite's durability and performance in applications such as batteries and industrial electrodes.

Purity and Chemical Stability Considerations

Graphite with binders often contains additives that can compromise its chemical purity and reduce stability under high-temperature or reactive environments. In contrast, binder-free graphite offers superior chemical stability and higher purity, making it ideal for applications requiring minimal contamination and consistent performance. The absence of binders also enhances the graphite's resistance to chemical degradation, ensuring longevity in demanding conditions.

Manufacturing Processes: Binder Inclusion vs Exclusion

In graphite manufacturing, the inclusion of binders enhances mechanical strength and machinability by providing cohesion during particle processing, which is crucial in extrusion and molding techniques. Binder-free processes rely on high-purity graphite powders that are sintered or pressed without additives, resulting in superior thermal and electrical conductivity but reduced structural integrity. Selecting between binder and no-binder methods depends on the desired balance between mechanical properties and functional performance in applications such as electrodes, refractory materials, and battery anodes.

Applications Best Suited for Binder-Free Graphite

Binder-free graphite excels in high-performance battery anodes where maximum energy density and enhanced electrical conductivity are critical, such as in electric vehicle (EV) batteries and portable electronics. Its binder-free structure reduces inactive materials, allowing for improved charge-discharge rates and longer cycle life, making it ideal for fast-charging applications. Industrial uses requiring lightweight, high-capacity energy storage systems also benefit from binder-free graphite due to its superior electrochemical stability and mechanical integrity.

Future Trends: Innovations in Graphite Binder Technology

Advancements in graphite binder technology are driving significant improvements in thermal stability, conductivity, and mechanical strength for battery electrodes. Emerging bio-based and synthetic polymer binders enhance electrode flexibility and environmental sustainability while maintaining electrochemical performance. Future trends emphasize the integration of nanomaterials and conductive additives to optimize binder functionality and support next-generation energy storage solutions.

Binders vs No Binders Infographic

materialdif.com

materialdif.com