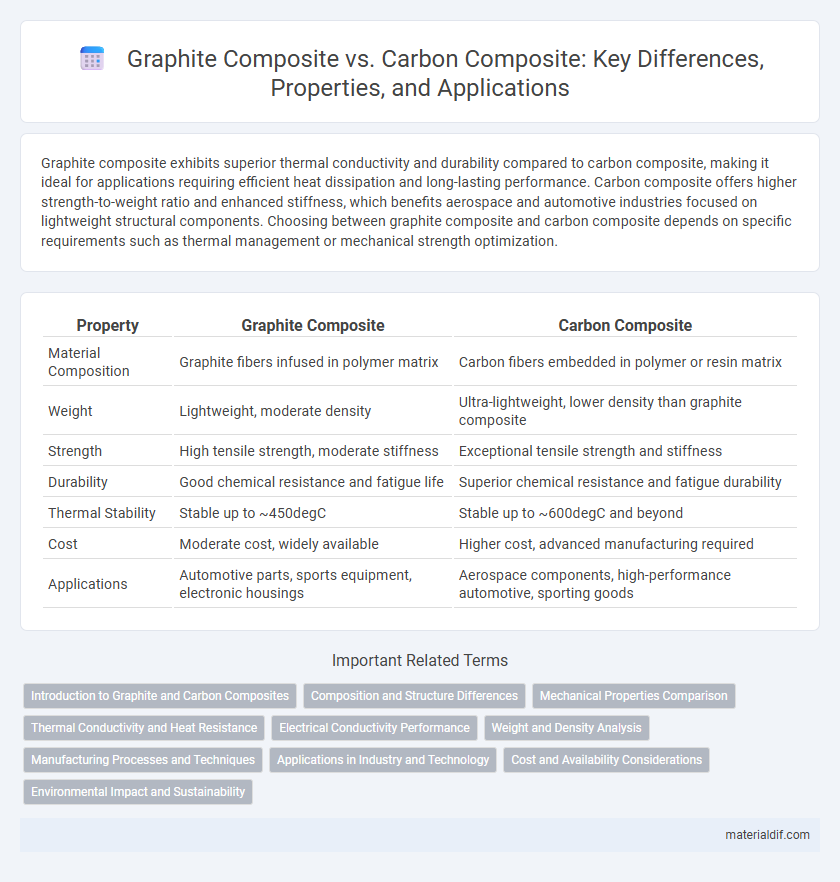

Graphite composite exhibits superior thermal conductivity and durability compared to carbon composite, making it ideal for applications requiring efficient heat dissipation and long-lasting performance. Carbon composite offers higher strength-to-weight ratio and enhanced stiffness, which benefits aerospace and automotive industries focused on lightweight structural components. Choosing between graphite composite and carbon composite depends on specific requirements such as thermal management or mechanical strength optimization.

Table of Comparison

| Property | Graphite Composite | Carbon Composite |

|---|---|---|

| Material Composition | Graphite fibers infused in polymer matrix | Carbon fibers embedded in polymer or resin matrix |

| Weight | Lightweight, moderate density | Ultra-lightweight, lower density than graphite composite |

| Strength | High tensile strength, moderate stiffness | Exceptional tensile strength and stiffness |

| Durability | Good chemical resistance and fatigue life | Superior chemical resistance and fatigue durability |

| Thermal Stability | Stable up to ~450degC | Stable up to ~600degC and beyond |

| Cost | Moderate cost, widely available | Higher cost, advanced manufacturing required |

| Applications | Automotive parts, sports equipment, electronic housings | Aerospace components, high-performance automotive, sporting goods |

Introduction to Graphite and Carbon Composites

Graphite composites consist of graphite fibers embedded in a resin matrix, offering high thermal conductivity and excellent electrical properties, making them ideal for aerospace and automotive applications. Carbon composites, on the other hand, feature carbon fibers with superior tensile strength and stiffness, widely used in sports equipment and structural components. Both materials provide lightweight, high-performance solutions, but graphite composites excel in heat dissipation while carbon composites prioritize mechanical strength.

Composition and Structure Differences

Graphite composites primarily consist of graphite fibers embedded in a polymer matrix, offering high thermal conductivity and electrical properties due to the layered structure of graphite. Carbon composites use carbon fibers with a similar polymer matrix but feature a more amorphous carbon structure, resulting in superior strength and stiffness. The fundamental difference lies in the crystalline arrangement of graphite fibers versus the more random carbon fiber alignment, affecting mechanical and thermal performance.

Mechanical Properties Comparison

Graphite composite exhibits higher stiffness and superior tensile strength compared to standard carbon composite, making it ideal for applications requiring enhanced load-bearing capacity. The enhanced fiber-matrix bonding in graphite composites contributes to better fatigue resistance and improved impact toughness. Thermal conductivity in graphite composites also surpasses that of carbon composites, aiding in heat dissipation during mechanical stress.

Thermal Conductivity and Heat Resistance

Graphite composites exhibit superior thermal conductivity compared to carbon composites, making them ideal for heat dissipation applications in electronics and aerospace industries. Their inherent ability to withstand high temperatures without significant degradation enhances operational durability in extreme thermal environments. Carbon composites, while strong and lightweight, generally have lower thermal conductivity and moderate heat resistance, limiting their use in high-heat settings.

Electrical Conductivity Performance

Graphite composites exhibit superior electrical conductivity compared to carbon composites due to the high crystallinity and graphitic structure of graphite fibers, which facilitate efficient electron transport. Carbon composites, often composed of amorphous carbon or carbon fibers, demonstrate lower conductivity because of disrupted electron pathways and increased resistivity. This performance difference makes graphite composites preferred in applications requiring rapid electrical signal transmission and minimal resistance.

Weight and Density Analysis

Graphite composites exhibit a lower density compared to carbon composites, resulting in a lighter material suitable for aerospace and automotive applications where weight reduction is critical. The density of graphite composites typically ranges from 1.6 to 2.0 g/cm3, whereas carbon composites can have densities between 1.75 to 2.2 g/cm3, affecting the overall structural weight. This weight difference directly influences the performance efficiency and fuel economy in engineering designs requiring high strength-to-weight ratios.

Manufacturing Processes and Techniques

Graphite composite manufacturing typically involves layering graphite fibers with resin matrices through processes like vacuum bagging and autoclaving, which ensure uniform resin distribution and high structural integrity. Carbon composite production often utilizes advanced techniques such as resin transfer molding (RTM) and prepreg layering, allowing for precise control over fiber orientation and resin content, enhancing mechanical properties. Both materials require meticulous curing protocols, but carbon composites benefit from higher-temperature curing cycles, resulting in superior strength-to-weight ratios.

Applications in Industry and Technology

Graphite composites are widely used in high-temperature applications such as aerospace components and thermal management systems due to their excellent heat resistance and electrical conductivity. Carbon composites, known for their superior strength-to-weight ratio and stiffness, dominate industries like automotive manufacturing, sports equipment, and structural engineering. Both materials contribute significantly to advancing lightweight, durable, and high-performance technologies in various industrial sectors.

Cost and Availability Considerations

Graphite composites generally offer a more cost-effective solution compared to carbon composites due to the lower price of raw graphite materials and simpler manufacturing processes. Availability of graphite composites tends to be higher, as graphite is more abundant and less sensitive to supply chain fluctuations than carbon fiber, which often relies on specialized production facilities. These factors make graphite composites a preferred choice for applications requiring budget efficiency and consistent material supply.

Environmental Impact and Sustainability

Graphite composites exhibit lower environmental impact compared to carbon composites due to their less energy-intensive production and higher recyclability rates, reducing landfill waste. Carbon composites, while offering superior strength-to-weight ratios, involve more complex recycling processes and higher carbon emissions during manufacturing, raising sustainability concerns. Advances in sustainable material sourcing and recycling technologies are critical to minimizing the ecological footprint of both composites in aerospace and automotive industries.

Graphite Composite vs Carbon Composite Infographic

materialdif.com

materialdif.com