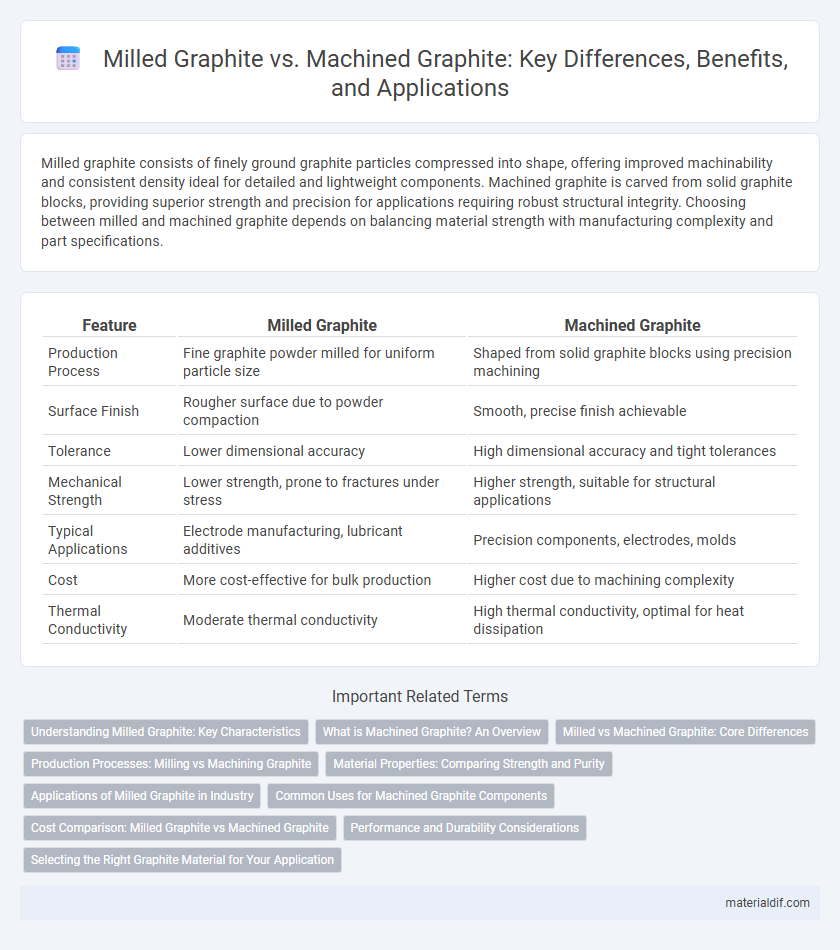

Milled graphite consists of finely ground graphite particles compressed into shape, offering improved machinability and consistent density ideal for detailed and lightweight components. Machined graphite is carved from solid graphite blocks, providing superior strength and precision for applications requiring robust structural integrity. Choosing between milled and machined graphite depends on balancing material strength with manufacturing complexity and part specifications.

Table of Comparison

| Feature | Milled Graphite | Machined Graphite |

|---|---|---|

| Production Process | Fine graphite powder milled for uniform particle size | Shaped from solid graphite blocks using precision machining |

| Surface Finish | Rougher surface due to powder compaction | Smooth, precise finish achievable |

| Tolerance | Lower dimensional accuracy | High dimensional accuracy and tight tolerances |

| Mechanical Strength | Lower strength, prone to fractures under stress | Higher strength, suitable for structural applications |

| Typical Applications | Electrode manufacturing, lubricant additives | Precision components, electrodes, molds |

| Cost | More cost-effective for bulk production | Higher cost due to machining complexity |

| Thermal Conductivity | Moderate thermal conductivity | High thermal conductivity, optimal for heat dissipation |

Understanding Milled Graphite: Key Characteristics

Milled graphite is characterized by its finely ground particles produced through a milling process, resulting in a more uniform and consistent particle size compared to machined graphite. This form of graphite offers enhanced compressibility and improved homogeneity, making it ideal for applications requiring precise shaping and fine detail. Its unique microstructure provides superior thermal and electrical conductivity, distinguishing it from the coarser, mechanically cut machined graphite.

What is Machined Graphite? An Overview

Machined graphite is a type of graphite material precisely shaped through advanced machining processes to achieve tight tolerances, smooth surface finishes, and intricate geometries essential for high-performance industrial applications. Unlike milled graphite, which is granulated and often used in powdered form, machined graphite maintains its solid structure and is customized for components such as electrodes, molds, and heat sinks. This form of graphite offers exceptional thermal conductivity, chemical resistance, and mechanical stability, making it ideal for semiconductor manufacturing, aerospace, and electromagnetic shielding.

Milled vs Machined Graphite: Core Differences

Milled graphite consists of finely ground particles pressed into shapes, offering high purity and excellent thermal conductivity ideal for precision applications. Machined graphite is cut or carved from larger graphite blocks, providing superior mechanical strength and dimensional accuracy for complex geometries. The core differences between milled and machined graphite lie in their manufacturing processes, particle size distribution, and suitability for applications requiring either intricate design or enhanced material resilience.

Production Processes: Milling vs Machining Graphite

Milled graphite is produced by grinding raw graphite into fine powder, which is then pressed into specific shapes before being baked and heated to high temperatures, resulting in a dense, uniform structure ideal for complex geometries. Machined graphite starts as a solid block or billet, which is cut, drilled, or shaped using CNC machines to achieve precise dimensions and surface finishes necessary for high-performance applications. Milling offers rapid production of intricate forms from powder, while machining provides superior dimensional accuracy and surface detailing from solid graphite material.

Material Properties: Comparing Strength and Purity

Milled graphite exhibits higher purity levels due to its refined particle size and controlled processing, resulting in minimal impurities and consistent material composition. Machined graphite offers superior strength and structural integrity, achieved through precise shaping techniques that enhance density and surface finish. While milled graphite is optimized for chemical stability, machined graphite excels in mechanical performance, making each suitable for distinct industrial applications.

Applications of Milled Graphite in Industry

Milled graphite, known for its fine particle size and high purity, is extensively used in industries such as batteries, lubricants, and conductive coatings due to its excellent electrical conductivity and lubrication properties. Its application in lithium-ion batteries enhances electrode performance and energy efficiency, while in lubricants, it reduces friction and wear in heavy machinery. Additionally, milled graphite's uniform particle distribution improves the quality and consistency of conductive inks and coatings in electronics manufacturing.

Common Uses for Machined Graphite Components

Machined graphite components are commonly used in high-temperature industrial applications such as semiconductor manufacturing, where precision and thermal stability are critical. These components serve in electrode holders, heat exchangers, and vacuum furnace parts due to their excellent conductivity and resistance to thermal shock. Industries like aerospace, automotive, and electronic production rely on machined graphite for custom-shaped parts that require durability and dimensional accuracy.

Cost Comparison: Milled Graphite vs Machined Graphite

Milled graphite typically offers a lower cost compared to machined graphite due to its less complex manufacturing process and reduced labor requirements. Machined graphite requires precision CNC machining, leading to higher production expenses and longer lead times. Cost-efficiency of milled graphite makes it suitable for high-volume applications where tight tolerances are less critical.

Performance and Durability Considerations

Milled graphite offers enhanced thermal conductivity and uniform particle size, improving performance in applications requiring precise heat management, while machined graphite provides superior dimensional accuracy and surface finish critical for high-precision components. Durability considerations favor machined graphite for its structural integrity and resistance to abrasion, whereas milled graphite may exhibit reduced mechanical strength but better adaptability in composite materials. Selecting between milled and machined graphite depends on balancing thermal performance requirements with the need for mechanical robustness in demanding industrial environments.

Selecting the Right Graphite Material for Your Application

Selecting the right graphite material hinges on the specific application requirements, where milled graphite offers excellent thermal conductivity and is ideal for applications needing high surface area and easy dispersion, such as electrodes or lubricants. Machined graphite provides superior precision, dimensional stability, and strength, making it suitable for complex-shaped components in industries like aerospace, semiconductors, and automotive manufacturing. Understanding these material properties helps optimize performance, durability, and cost-effectiveness in industrial processes.

Milled Graphite vs Machined Graphite Infographic

materialdif.com

materialdif.com