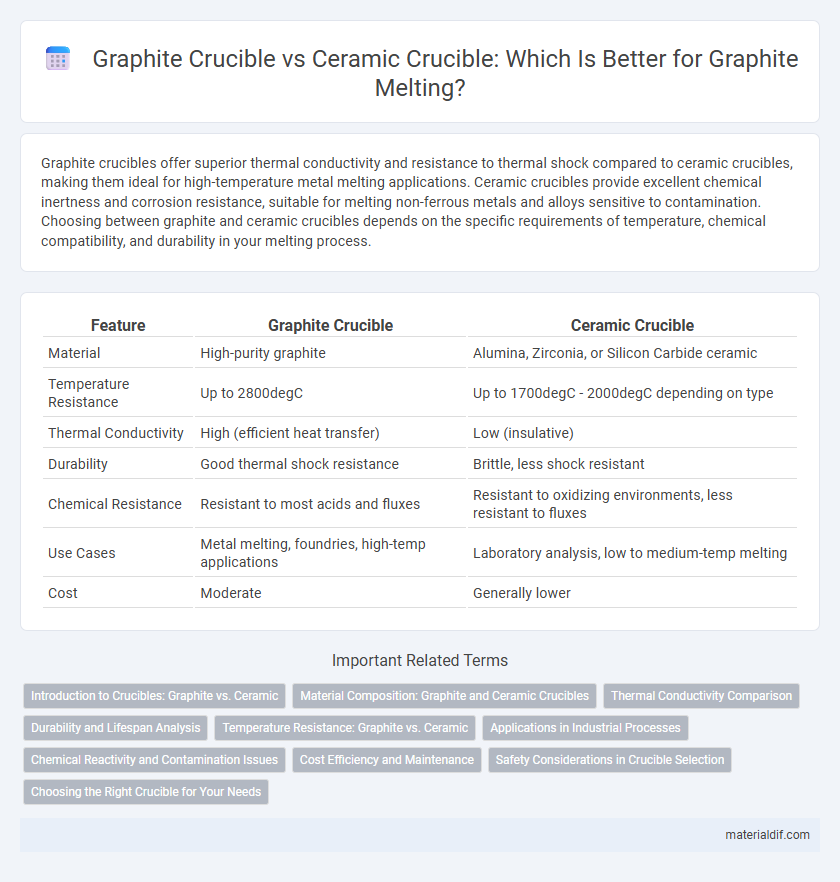

Graphite crucibles offer superior thermal conductivity and resistance to thermal shock compared to ceramic crucibles, making them ideal for high-temperature metal melting applications. Ceramic crucibles provide excellent chemical inertness and corrosion resistance, suitable for melting non-ferrous metals and alloys sensitive to contamination. Choosing between graphite and ceramic crucibles depends on the specific requirements of temperature, chemical compatibility, and durability in your melting process.

Table of Comparison

| Feature | Graphite Crucible | Ceramic Crucible |

|---|---|---|

| Material | High-purity graphite | Alumina, Zirconia, or Silicon Carbide ceramic |

| Temperature Resistance | Up to 2800degC | Up to 1700degC - 2000degC depending on type |

| Thermal Conductivity | High (efficient heat transfer) | Low (insulative) |

| Durability | Good thermal shock resistance | Brittle, less shock resistant |

| Chemical Resistance | Resistant to most acids and fluxes | Resistant to oxidizing environments, less resistant to fluxes |

| Use Cases | Metal melting, foundries, high-temp applications | Laboratory analysis, low to medium-temp melting |

| Cost | Moderate | Generally lower |

Introduction to Crucibles: Graphite vs. Ceramic

Graphite crucibles offer excellent thermal conductivity and resistance to thermal shock, making them ideal for high-temperature metal melting applications, especially in foundries and laboratories. Ceramic crucibles provide superior chemical inertness and can withstand extreme corrosive environments, commonly used in chemical analysis and material science. Both types serve distinct purposes based on the temperature range, chemical compatibility, and mechanical strength required for specific industrial or scientific processes.

Material Composition: Graphite and Ceramic Crucibles

Graphite crucibles are composed primarily of pure graphite, offering exceptional thermal conductivity and resistance to thermal shock, which makes them ideal for high-temperature metal melting applications. Ceramic crucibles, made from materials such as alumina, zirconia, or silicon carbide, provide excellent chemical inertness and high-temperature stability but have lower thermal conductivity compared to graphite. The choice between graphite and ceramic crucibles depends on the specific melting requirements, including temperature range, chemical reactivity, and thermal shock resistance.

Thermal Conductivity Comparison

Graphite crucibles exhibit significantly higher thermal conductivity than ceramic crucibles, typically around 120-150 W/m*K compared to ceramic's 1-3 W/m*K, allowing faster heating and cooling cycles in metallurgical processes. This superior heat transfer capability enhances energy efficiency and temperature uniformity during melting or alloying operations. However, ceramic crucibles offer better resistance to high-temperature corrosion and thermal shock, making them suitable for different industrial applications despite lower thermal conductivity.

Durability and Lifespan Analysis

Graphite crucibles exhibit superior thermal shock resistance and longer lifespans compared to ceramic crucibles, making them ideal for high-temperature industrial applications. The inherent porosity and brittleness of ceramic crucibles often result in reduced durability and a higher risk of cracking during rapid temperature changes. Graphite's robust structure ensures enhanced durability, sustaining functionality over extended use cycles under extreme conditions.

Temperature Resistance: Graphite vs. Ceramic

Graphite crucibles offer superior temperature resistance, typically enduring continuous use up to 3000degC, ideal for high-temperature metal melting and casting applications. Ceramic crucibles generally withstand temperatures around 1600degC to 1800degC, making them suitable for moderate temperature processes but less effective for ultra-high temperature operations. The high thermal conductivity and structural integrity of graphite make it preferable for applications requiring rapid temperature changes and extreme heat tolerance compared to ceramic crucibles.

Applications in Industrial Processes

Graphite crucibles excel in high-temperature industrial processes such as metal casting, alloy production, and melting non-ferrous metals due to their superior thermal conductivity and resistance to thermal shock. Ceramic crucibles are preferred in applications requiring chemical inertness and resistance to oxidation, such as in laboratory-scale chemical reactions and high-purity material processing. The choice between graphite and ceramic crucibles depends on the specific industrial application's temperature requirements, chemical compatibility, and mechanical strength needs.

Chemical Reactivity and Contamination Issues

Graphite crucibles exhibit low chemical reactivity with most metals and alloys, reducing the risk of contamination during high-temperature processes. Ceramic crucibles, while resistant to oxidation, may release impurities due to their porous structure, potentially contaminating sensitive materials. The superior purity and chemical stability of graphite crucibles make them preferable for applications requiring minimal contamination.

Cost Efficiency and Maintenance

Graphite crucibles offer superior cost efficiency compared to ceramic crucibles due to their faster heating and cooling rates, resulting in reduced energy consumption and shorter cycle times. Maintenance requirements for graphite crucibles are lower because of their resistance to thermal shock and chemical corrosion, leading to extended lifespan and fewer replacements. Ceramic crucibles, while durable at high temperatures, often require more frequent inspections and careful handling to prevent cracking, increasing overall maintenance costs.

Safety Considerations in Crucible Selection

Graphite crucibles offer superior thermal shock resistance and excellent heat conductivity, reducing the risk of fractures during rapid temperature changes, which enhances safety in high-temperature applications. Ceramic crucibles, while chemically inert and stable at very high temperatures, are more brittle and prone to cracking under thermal stress, posing potential safety hazards. Selecting the appropriate crucible depends on balancing the material's thermal properties and mechanical strength to ensure safe handling and operation in metallurgical processes.

Choosing the Right Crucible for Your Needs

Graphite crucibles offer superior thermal conductivity and resistance to thermal shock, making them ideal for high-temperature metal melting and casting applications. Ceramic crucibles provide excellent chemical stability and are suitable for corrosive environments but generally have lower thermal conductivity and higher fragility compared to graphite. Choosing the right crucible depends on factors like temperature requirements, material compatibility, and whether thermal shock resistance or chemical inertness is prioritized.

Graphite Crucible vs Ceramic Crucible Infographic

materialdif.com

materialdif.com